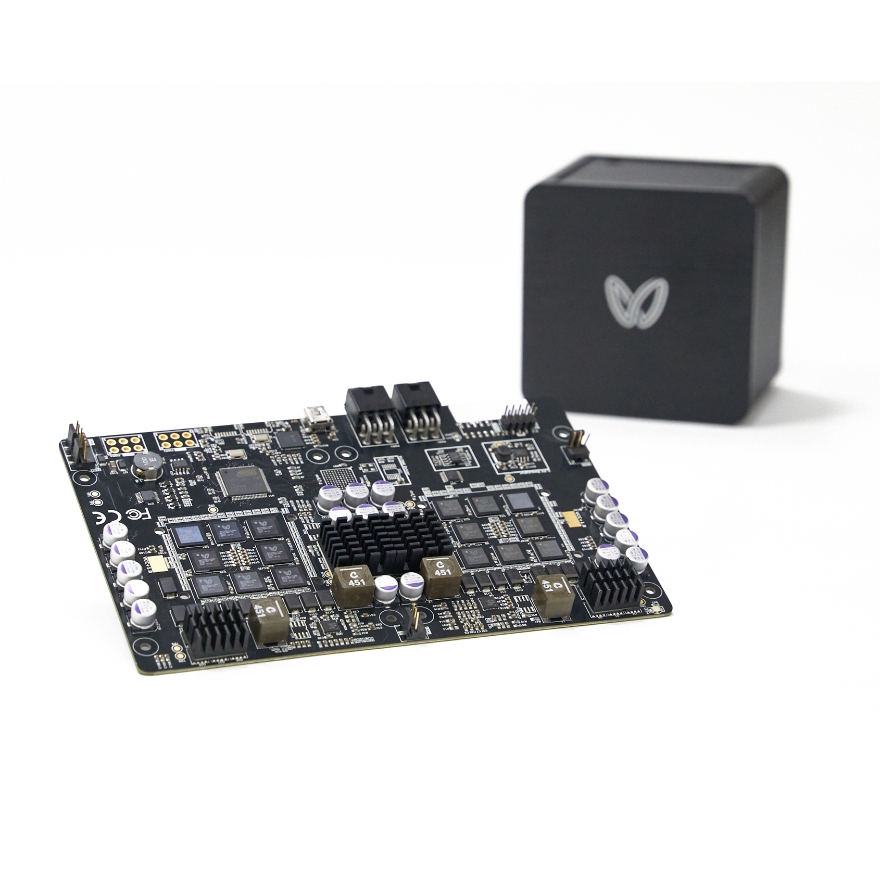

High Quality PCBs

High Quality PCBs & Quick Turn Supply

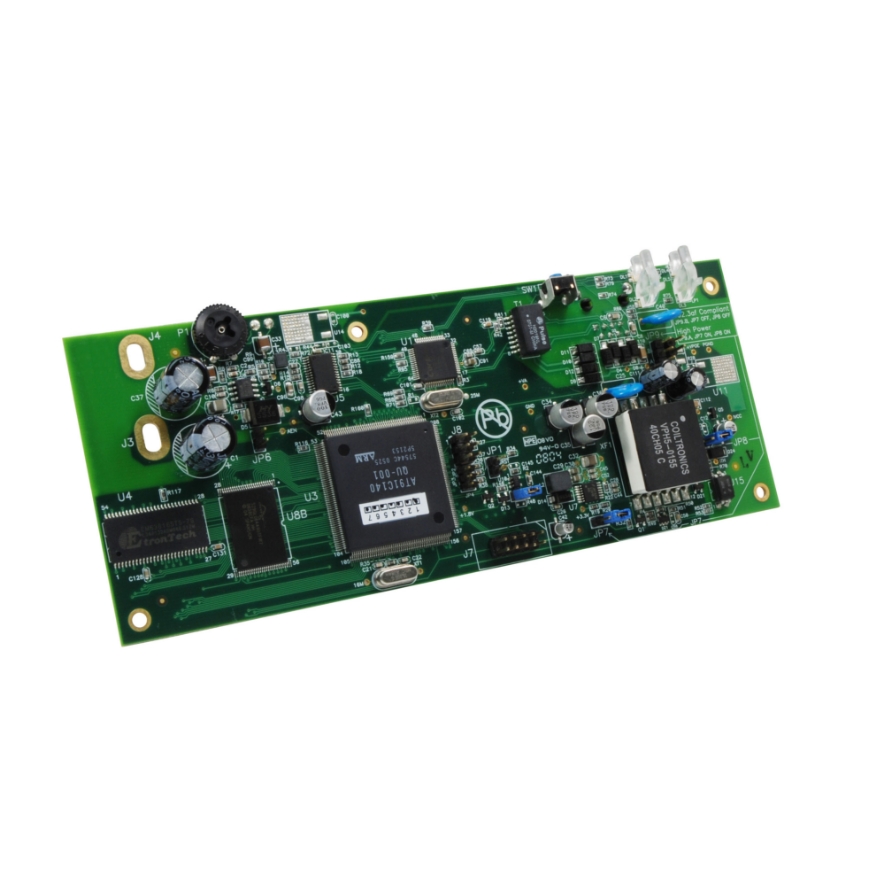

At DMax, we offer a comprehensive range of high-quality PCB products, backed by reliable global sourcing and materials management services, ensuring consistent and cost-effective PCB supply for your projects.

- DMax provides a variety of PCB types to meet diverse industry needs:

- Multilayer PCBs:

Designed for complex circuits with high-density requirements.

- High Frequency PCBs:

Optimized for high-speed applications.

- High-Density Interconnect (HDI) Multilayer PCBs:

Offering superior performance and miniaturization.

- FPC Multilayer/2 Layer FCCL:

Flexible PCBs ideal for compact and flexible designs.

- Rigid-Flex Boards:

Combining the benefits of rigid and flexible circuits in one product.

PCB Production Capabilities

Our PCB production capabilities ensure we meet even the most demanding technical requirements:

Multilayer PCBs

-

Base Materials

FR-4, HIGH TG FR-4, FCCL, HB, 94V-0,

Aluminum, Arlon, Taconic, Teflon, Rogers. -

Layers

Single layer up to 40 layers.

-

Copper Foil Thickness

Inner layer: 0.5oz to 4oz;

Outer layer: 0.5oz to 6oz. -

Finished Board

Thickness

2 Layers: Minimum 0.2mm.

4 Layers: Minimum 0.4mm.

Multilayers: 0.4mm to 7.0mm. -

Minimum Hole Size

Mechanical drill: 0.15mm;

Laser drill: 0.1mm. -

Minimum Trace/Width

2.5/2.5 mil (63.5/63.5 μm).

-

HDI Design

Blind and buried micro-via available.

-

Impedance Control

Differential and single-end within ±5%.

FPC Boards

-

Layers

1 to 8 layers.

-

Minimum Board

Thickness

70μm.

-

Minimum Hole Size

4mil(0.10mm).

-

Minimum Trace/Width

2mil/2mil (0.05mm)

-

Solder Mask

Smallest print width: 3mil.

-

Surface Treatments

Immersion Gold (ENIG), Electrolytic (Bondable) & Electroless Soft Gold, Immersion Silver, Immersion Tin, ENEPIG, ENTEK.

-

We also offer a wide range of PCBA services to cater to various specifications. For detailed requirements, please Contact Us to discuss your project. For detailed requirements, please feel free to Contact Us to discuss your project!

- CONTACT

Quality Control

We ensure the highest standards of quality throughout our PCB production process:

-

ISO Certification

Our production facilities adhere to international quality management standards, ensuring consistency and reliability.

-

Advanced Testing Equipment

Inline Auto Optical Inspection (AOI), Solder Paste Inspection (SPI), and X-ray Inspection to detect defects and ensure precise quality control.

-

RoHS/REACH/Lead-Free Compliance

All our PCBs comply with environmental standards, including RoHS and REACH regulations, ensuring safe and eco-friendly products.

-

UL Certification

Our PCBs meet the rigorous requirements of UL standards for safety and performance.

Technical Advantages

Our PCBs are designed to offer superior performance in terms of electrical and mechanical properties:

-

High Conductivity

Materials such as FR-4, Teflon, and Metal Core PCB (Aluminum) ensure excellent conductivity and signal integrity.

-

Stability and Durability

With materials like 94V-0, HB, and FR-5, our PCBs offer outstanding thermal stability, fire resistance, and mechanical strength.

-

Precise Manufacturing

Our capabilities include fine trace/space with a minimum of 2.5/2.5 mil and high-precision drilling with laser drill capabilities as small as 0.1mm.

Application Scope

Our PCBs are used in a wide range of industries, including:

-

Electronics

Serving various applications, from consumer electronics to communication systems

-

Medical

High reliability for medical devices, ensuring performance and safety.

-

Automotive

Robust PCBs for automotive systems, designed to withstand harsh environments.

-

Industrial and Aerospace

Reliable and durable for use in complex industrial machinery and aerospace applications.

- PCB Assembly (PCBA)

- 6 SMT PCBA production lines

to meet high-volume manufacturing needs.

- Mounting Capabilities:

7,600,000 pcs/day for PCBA manufacturing.

- 2 DIP lines

for wave soldering, ideal for PCBA assembly.

- N2 Reflow:

For enhanced soldering quality in PCBA processes.

- Inline Auto Optical Inspection (AOI):

For precise PCBA quality control.

- Inline Solder Paste Inspection (SPI):

Tailored for PCBA soldering quality control.

- X-Ray Inspection:

Used for detecting defects in PCBA assemblies.

- ISO, UL Certified:

Ensuring compliance with production standards.

- Fully compliant with RoHS/REACH/Lead-Free regulations in PCBA manufacturing.

- Adheres to IPC-A-600/IPC-A-610 standards for PCBA quality assurance.

Quality Assurance

We maintain rigorous quality assurance standards to ensure the highest level of product reliability:

- Inline Auto Optical Inspection (AOI) for real-time defect detection

- Inline Solder Paste Inspection (SPI) to monitor paste application quality.

- X-ray Inspection to identify hidden defects in assemblies.

- A well-established QC team and system for continuous monitoring.

- Certified under ISO and UL quality standards.

- Fully compliant with RoHS/REACH/Lead-Free regulations.

- Adherence to IPC-A-600/IPC-A-610 standards for PCB and PCBA quality.

AOI

SPI

X-Ray Inspection

ISO, UL Certified

RoHS/REACH/Lead-Free

IPC-A-600/IPC-A-610

With DMax, you can expect reliable, high-quality PCBs and PCBA services for a wide range of applications, all while ensuring quick turnaround times, rigorous quality control, and regulatory compliance. Reach out to us today with your BOM and Gerber files to get started!

Contact US