Products

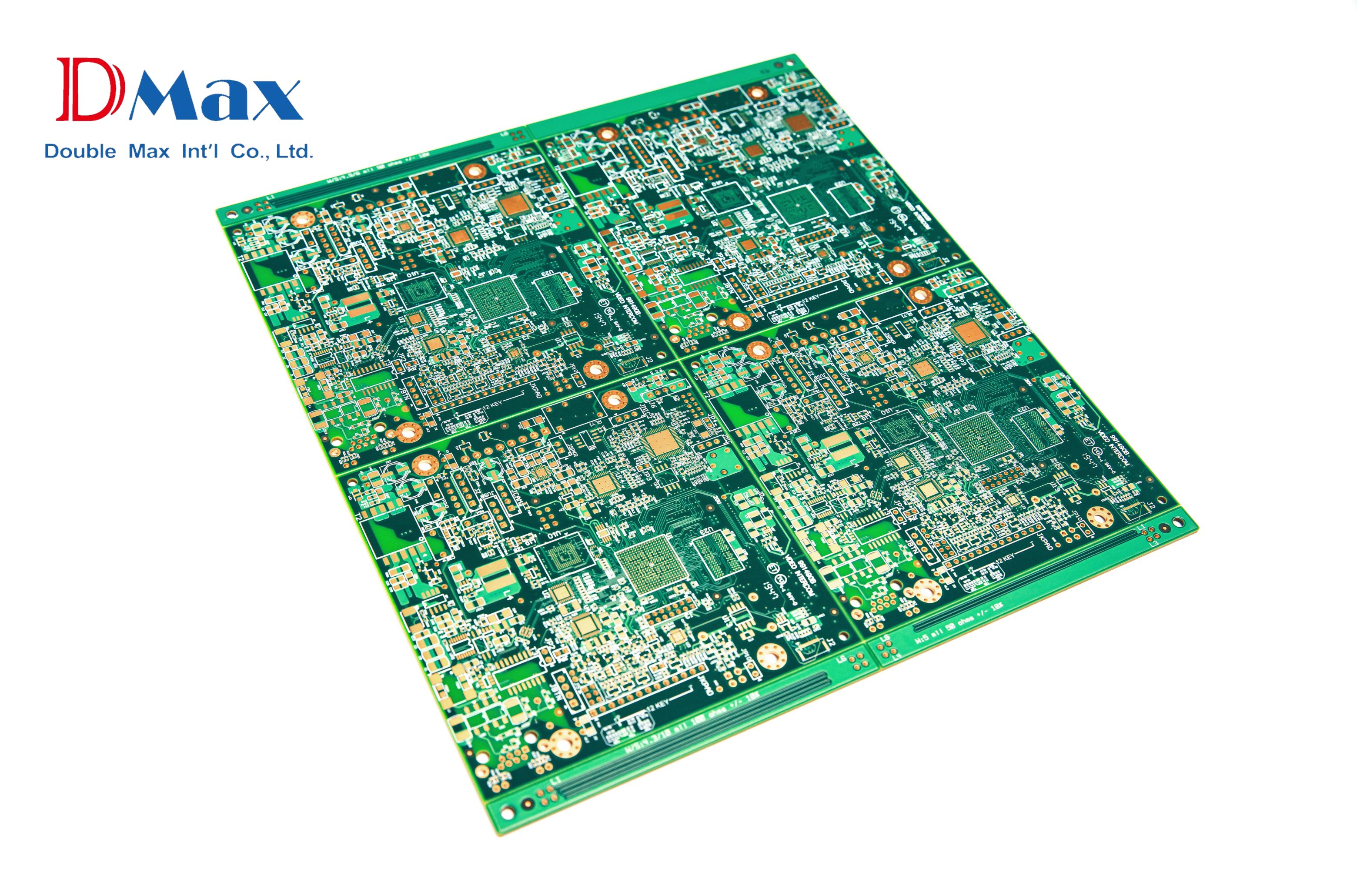

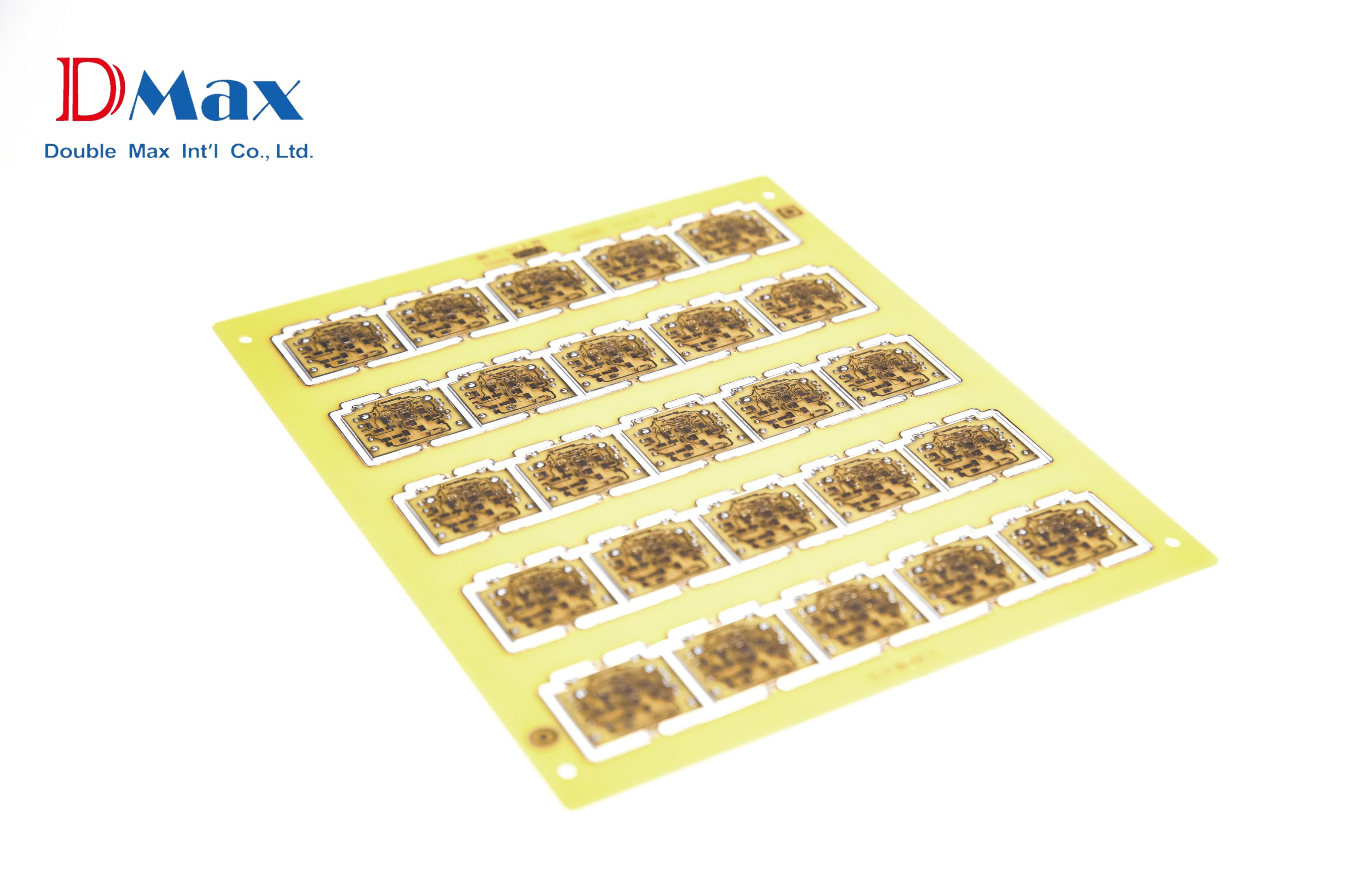

Rigid-Flex PCB Assembly

Model:

DMAX specializes in rigid-flex PCBs that combine the stability of rigid boards with the flexibility of FPC. Widely applied in aerospace, medical, and compact consumer devices, these PCBs reduce assembly complexity and improve reliability.

-

Online Quote

-

Upload PCB File

-

Order Review

-

Payment

-

Real-time Fabrication Tracking

-

Delivery

-

Confirm Received

DMAX – Rigid-Flex PCB Assembly Services

DMAX provides complete Rigid-Flex PCB assembly solutions for products requiring compact form factors, dynamic movement, and high reliability.

Rigid-Flex PCBs combine the structural stability of rigid boards with the flexibility of FPC, enabling 3D circuit designs that simplify wiring, reduce connectors, and improve durability under mechanical stress.

With over 25 years of PCB manufacturing and EMS expertise, DMAX delivers Rigid-Flex assemblies optimized for space-saving, vibration resistance, and complex system integration.

Advantages of Rigid-Flex PCB Technology

-

Combines rigid and flexible layers in a single interconnected design

-

Reduces interconnect failures by eliminating cables and connectors

-

Enables 3D folding, wrapping, and embedded designs

-

Improves signal integrity and electrical performance

-

Lightweight and ideal for mobile, medical, and aerospace applications

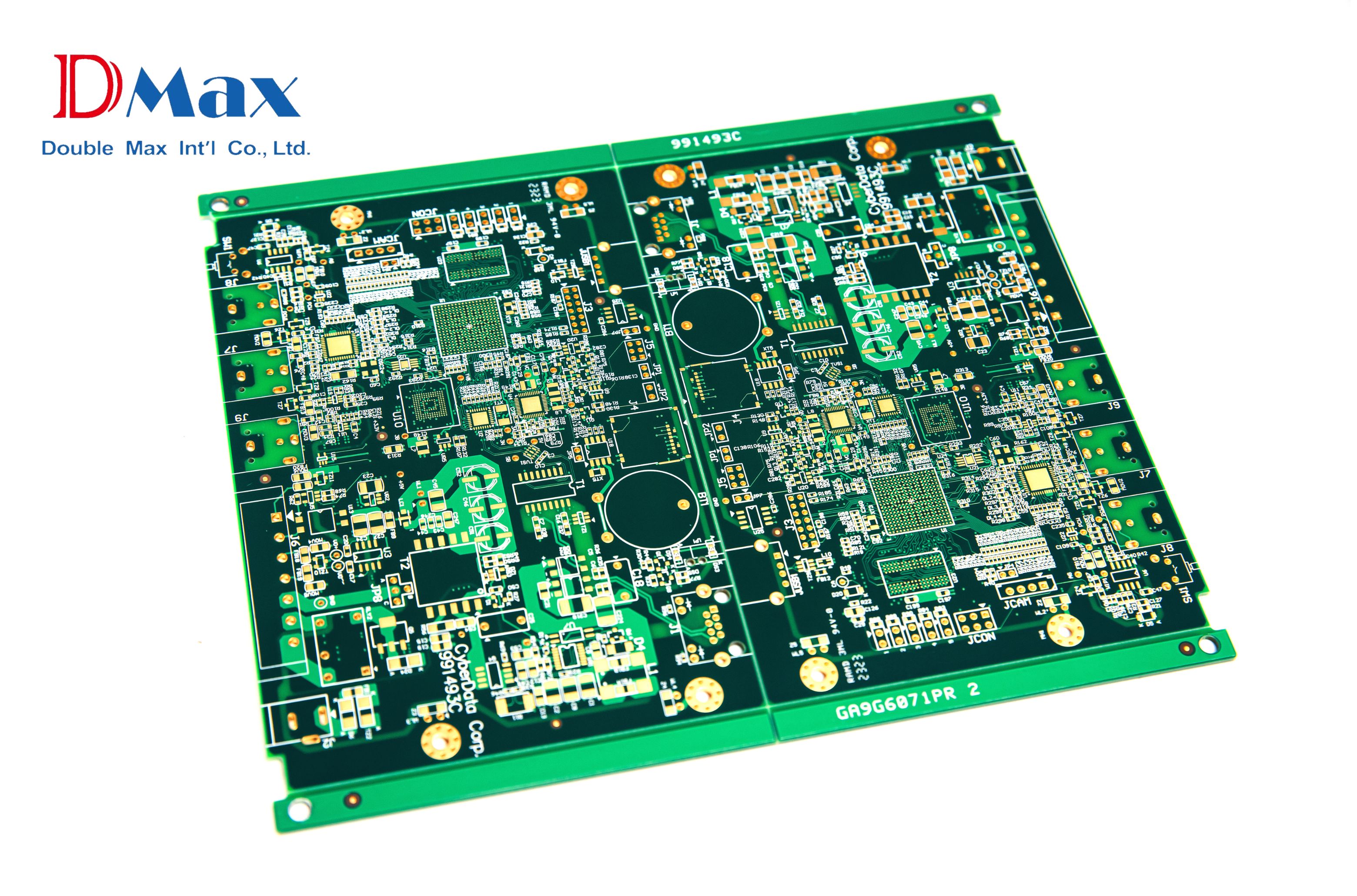

DMAX Rigid-Flex PCB Assembly Capabilities

-

Up to 10-layer rigid-flex stackups

-

Adhesiveless polyimide and high-Tg FR4 materials

-

Fine-pitch SMT with tight component placement on both rigid and flex zones

-

Laser cutting, stiffener bonding, and coverlay application

-

SMT/THT hybrid assembly with precision alignment

-

Comprehensive testing including bend-cycle, AOI, X-ray, and electrical validation

Applications We Serve

DMAX's Rigid-Flex PCB assemblies are used in:

-

Wearable health and medical monitoring devices

-

Aerospace navigation and instrumentation systems

-

Foldable or rotating display modules

-

Industrial handheld terminals

-

Compact automotive and EV modules

-

Military-grade portable electronics

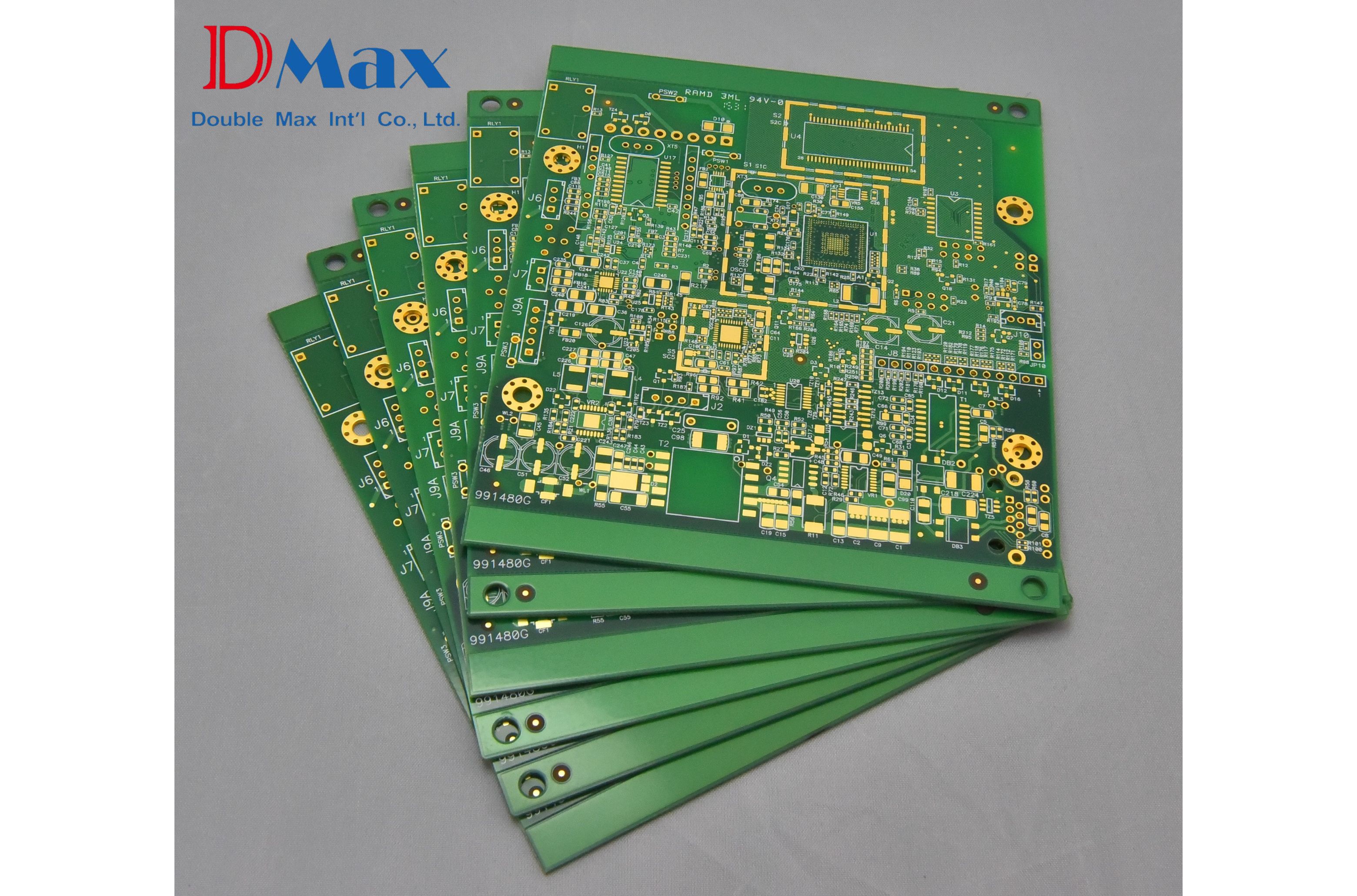

Why Choose DMAX for Rigid-Flex PCB Assembly

-

One-Stop Fabrication + Assembly:

DMAX offers full in-house support for Rigid-Flex PCB fabrication, component sourcing, SMT assembly, and final box build. -

Mechanical & Electrical Co-Design Support:

Our engineers collaborate with you to optimize layout, bend zones, and stiffener placement to reduce risk and enhance reliability. -

Low to High Volume Flexibility:

From prototype development to scalable mass production, DMAX accommodates flexible project scopes with fast lead times. -

Global EMS Experience:

Trusted by clients across medical, aerospace, industrial, and consumer electronics sectors for Rigid-Flex manufacturing excellence.

DMAX – Trusted Experts in Rigid-Flex PCB Integration

When space, flexibility, and performance matter, DMAX's Rigid-Flex PCB assembly services provide the robust, compact, and efficient solution your product needs.

Let us turn your complex mechanical-electrical challenge into a streamlined, manufacturable solution.

Contact DMAX to get started with your Rigid-Flex PCB project today.

FAQ

- What does a PCBA manufacturer typically provide?

- What are turnkey PCBA services and why are they important?

- Can a PCBA manufacturer support both prototyping and mass production?

- Which industries rely most heavily on PCBA manufacturing services?

- Which certifications should you verify when selecting a reliable PCBA manufacturer?

- What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

- What is a PCBA?

- What is a PCB?

- What is the difference between PCB and PCBA?

- What services does D-MAX's Turnkey PCBA provide?

- What is DFM? What is the importance of DFM for PCBA?

- What is Conformal Coating in PCBA?

- What is SMT? How do SMT work on my PCBA?

- What are the benefits of D-MAX's High-Speed SMT Technology for my PCBA?

- What is DIP? How is DIP technology applied in PCBA manufacturing?

- What is the difference between SMT and DIP? How should I choose for my PCBA?

- How is a Turnkey PCBA project quote calculated in D-MAX?

- How does D-MAX handle global electronic component shortages?

- Does the D-MAX PCBA Turnkey process include prototyping?

- During the PCBA design and production process, is there an NDA to protect my IP?

- PCBA 製造商通常提供什麼服務內容?

- 什麼是 Turnkey PCBA 服務?為何重要?

- PCBA 製造商能同時支援打樣與量產嗎?

- 哪些產業最依賴 PCBA 製造服務?

- 選擇可靠 PCBA 製造商時應檢驗哪些認證?

- PCBA 製造商常見的合作模式及選擇指南

- 台灣 PCBA 代工與 Turnkey PCBA 一站式服務|SMT/THT 組裝|DMAX

- Turnkey PCBA 一站式服務|PCBA 代工與 EMS

- PCBA 製造商能同時支援NPI試作與量產嗎?

- PCBA是什麼?

- PCB是什麼?

- D-MAX的Turnkey PCBA提供了哪些服務項目

- PCB跟PCBA的差異是什麼?

- 什麼是 DFM (可製造性設計)?DFM對PCBA的重要性?

- 什麼是三防漆?三防漆在PCBA上的作用是什麼?

- D-MAX 的 SMT 技術,對我的PCBA有什麼好處?

- D-MAX 的高速 SMT 技術,對我的PCBA有什麼好處?

- DIP 是什麼? DIP技術如何應用在 PCBA 的製造?

- SMT (表面貼裝) 和 DIP (通孔) 有什麼不同?我的產品該如何選擇?

- D-MAX Turnkey PCBA 專案的報價是如何計算的?

- D-MAX 如何應對全球性的 PCBA 電子元件缺料?

- D-MAX 的 PCBA Turnkey 製程裡包含打樣嗎?

- PCBA 的設計與生產過程中,有任何保密協議可以保護我的 IP 嗎?

- 台湾のPCBAメーカー|Turnkey PCBA・基板実装(EMS)|SMT/THT|DMAX

- ターンキーPCBAとは|基板実装(EMS)ワンストップの重要性とメリット|DMAX

- DMAX:試作から量産までのワンストップPCBAパートナー(台湾)

RECOMMENDATIONS

News