Products

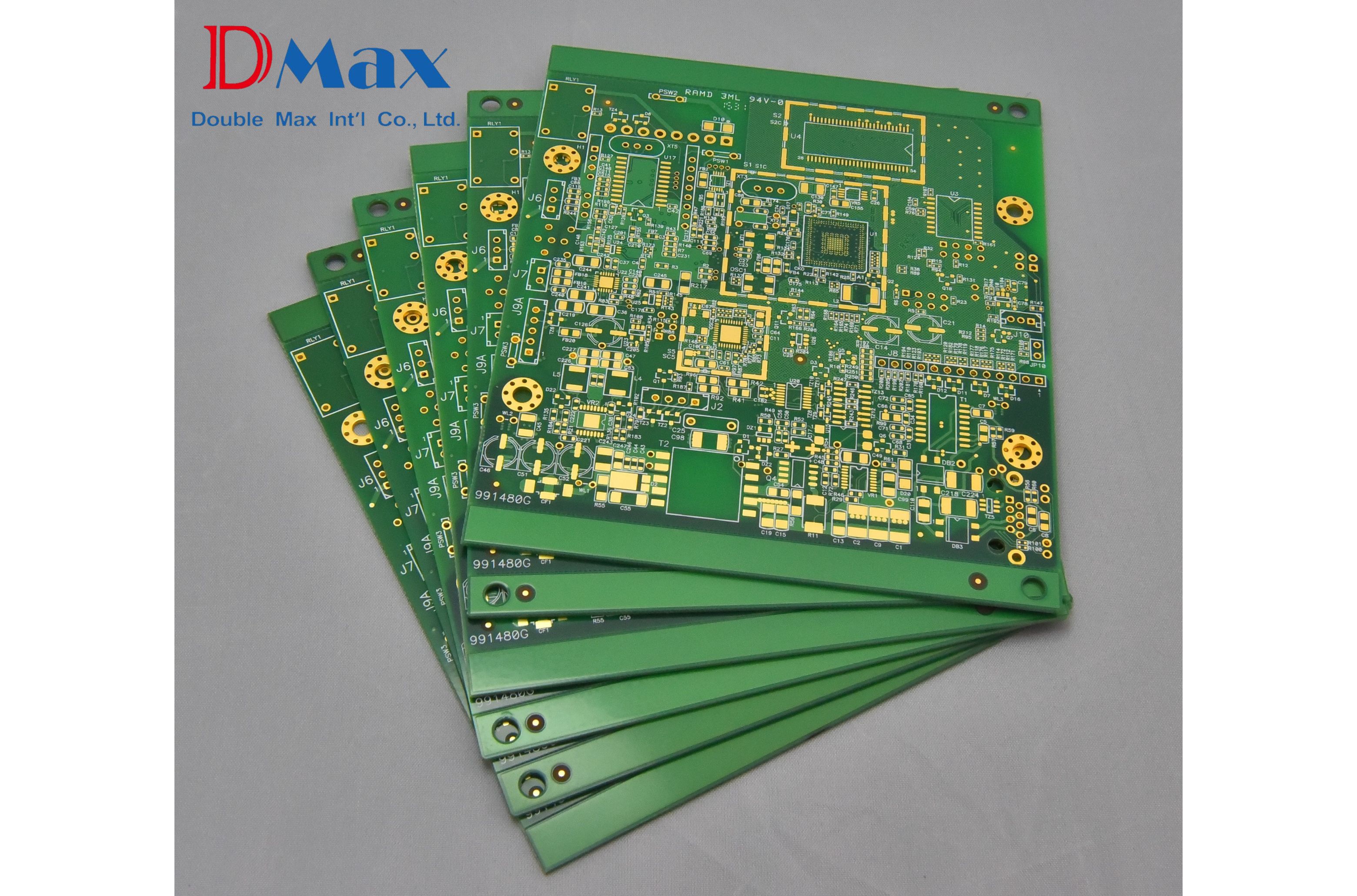

HDI (High Density Interconnect) PCBs

Model:

We provide High-Density Interconnect (HDI) PCBs with fine line widths, microvias, and laser drilling technology. Perfect for high-performance products requiring compact layouts, such as smartphones, tablets, and IoT devices.

-

Online Quote

-

Upload PCB File

-

Order Review

-

Payment

-

Real-time Fabrication Tracking

-

Delivery

-

Confirm Received

DMAX – HDI (High Density Interconnect) PCB Manufacturing

DMAX delivers high-performance HDI PCBs (High Density Interconnect PCBs) for compact, high-speed, and space-constrained electronic devices.

With advanced laser drilling, fine-line etching, and microvia stacking capabilities, DMAX enables multilayer HDI fabrication that meets the signal integrity and miniaturization demands of next-generation technology.

Backed by 25+ years of PCB experience, DMAX supports high-end product development across telecom, automotive, medical, and consumer electronics sectors.

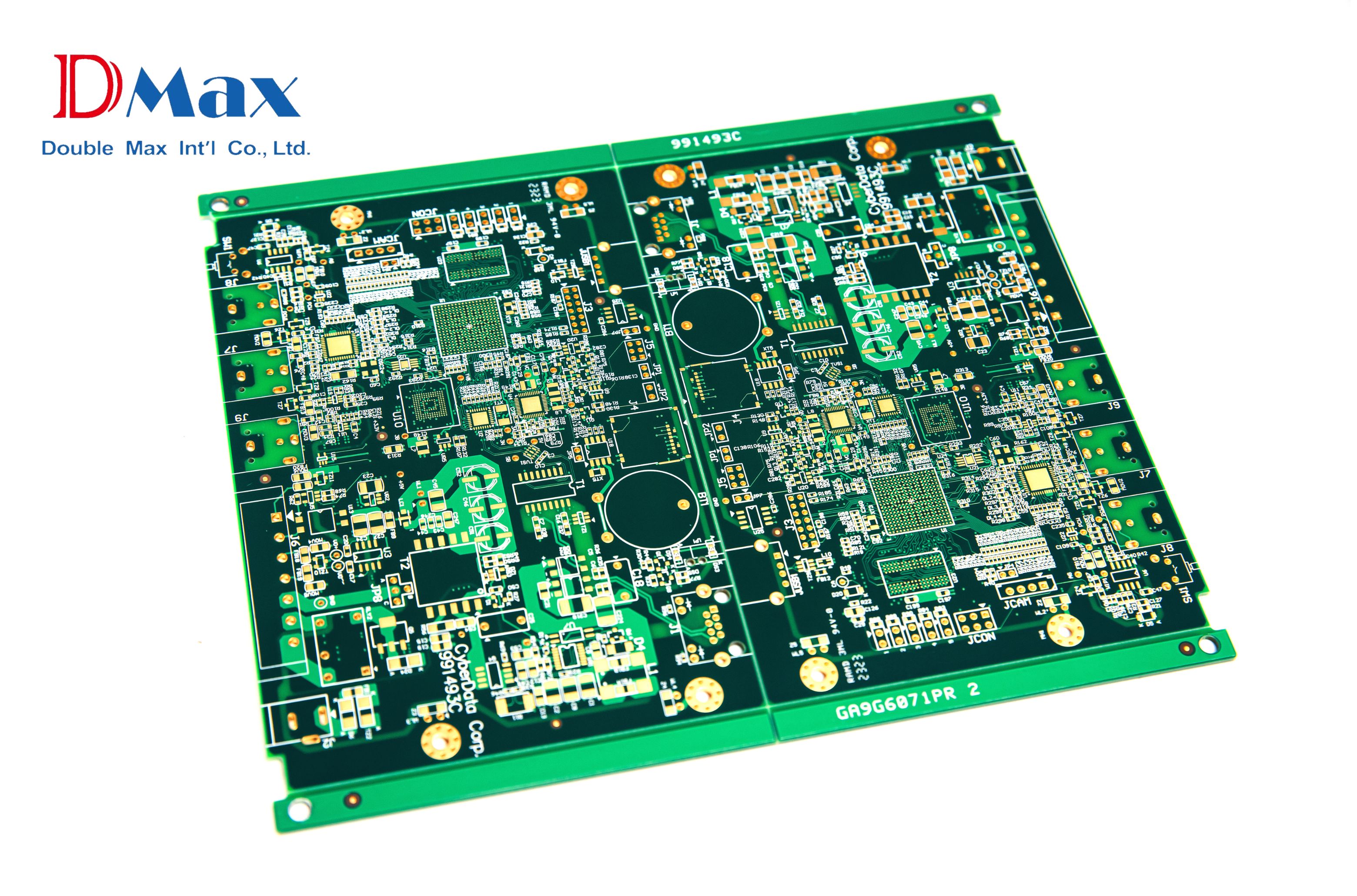

Key Features of DMAX HDI PCBs

-

4–12+ layers with microvias and blind/buried vias

-

Laser-drilled via-in-pad and stacked via structures

-

Minimum line/space: 3/3 mil or better

-

High-Tg and low-loss dielectric materials

-

Impedance-controlled multilayer stack-ups

-

Advanced surface finishes: ENIG, ENEPIG, OSP

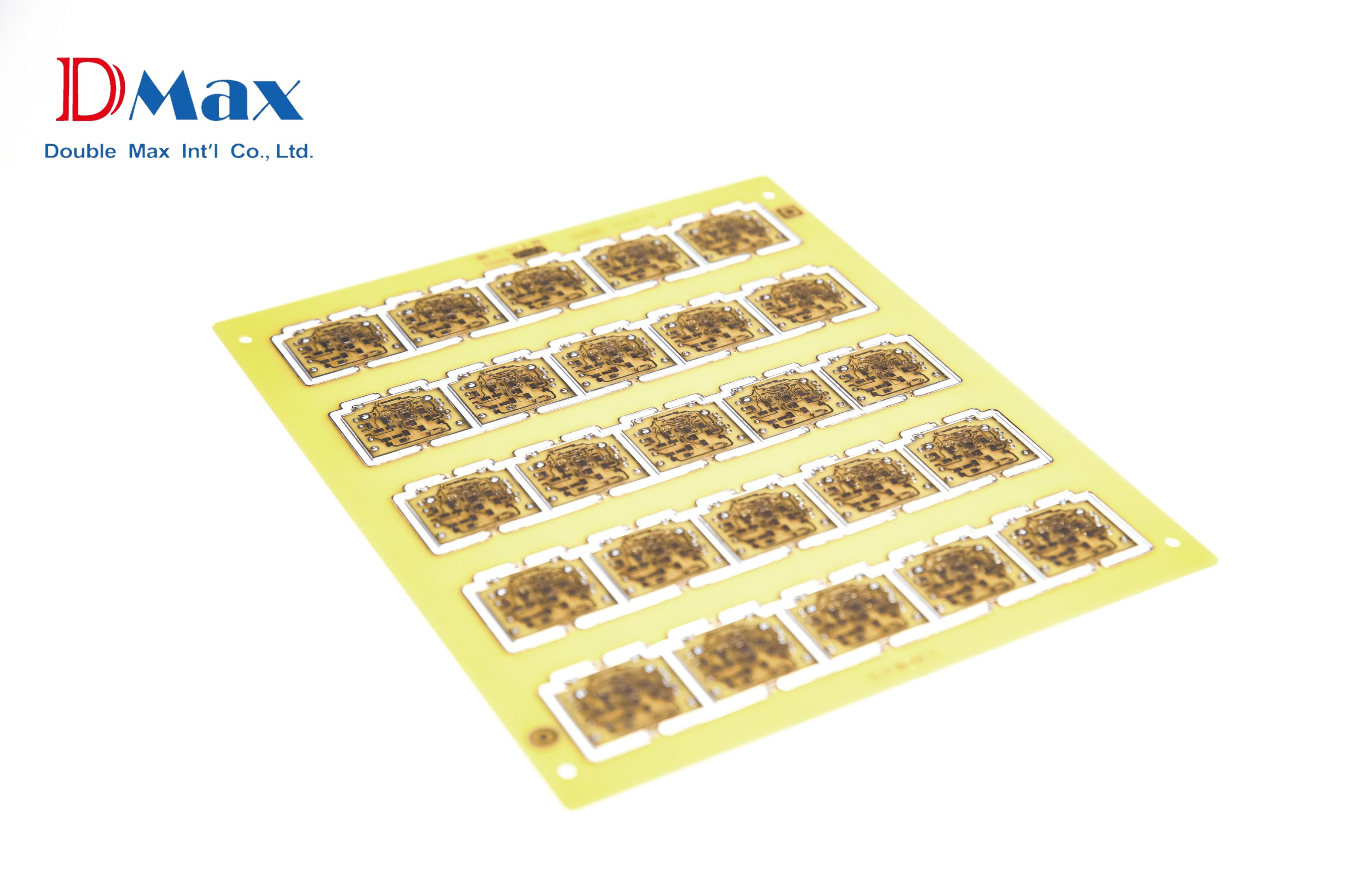

Typical Applications of HDI PCBs

DMAX's HDI technology powers a wide range of advanced electronics:

-

5G modules and high-frequency communication boards

-

Smartphone and tablet PCBs

-

Camera and image sensor boards

-

Medical diagnostic and implantable electronics

-

Automotive radar and infotainment systems

-

High-speed storage, SSD controllers, and networking gear

-

Compact wearable devices and smartwatches

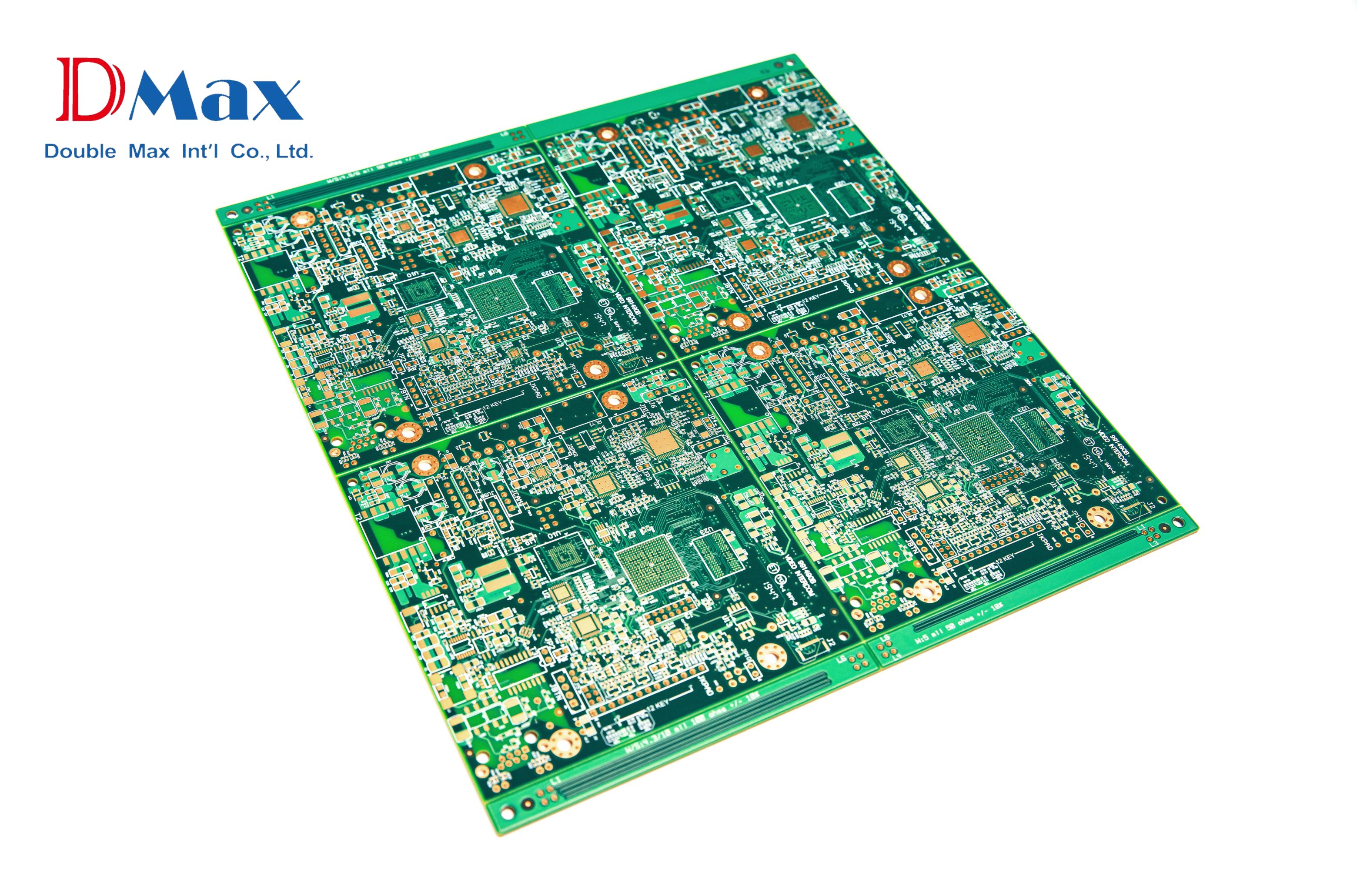

Why Choose DMAX for High Density Interconnect PCBs

-

Advanced Manufacturing Technology:

DMAX employs state-of-the-art equipment for laser drilling, copper plating, and fine-line imaging to achieve consistent HDI quality. -

Stack-Up and Signal Integrity Expertise:

Our engineers assist with material selection and impedance planning to ensure optimal high-speed performance in multilayer environments. -

High Precision & Tight Tolerances:

We meet strict dimensional and electrical specs required for ultra-dense boards in medical, RF, and mobile applications. -

Prototype to Mass Production Ready:

From HDI prototypes to full-volume production runs, DMAX provides fast turnaround and scalable capacity. -

Quality Guaranteed:

All boards undergo electrical testing, cross-section analysis, and IPC Class 2/3 inspections per project needs.

Partner with DMAX for Next-Generation HDI PCB Production

Whether you're building ultra-compact wearables or high-speed communications systems, DMAX's HDI PCB manufacturing services deliver the density, speed, and reliability that modern designs demand.

Contact DMAX today to discuss your HDI PCB requirements.

FAQ

- What does a PCBA manufacturer typically provide?

- What are turnkey PCBA services and why are they important?

- Can a PCBA manufacturer support both prototyping and mass production?

- Which industries rely most heavily on PCBA manufacturing services?

- Which certifications should you verify when selecting a reliable PCBA manufacturer?

- What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

- What is a PCBA?

- What is a PCB?

- What is the difference between PCB and PCBA?

- What services does D-MAX's Turnkey PCBA provide?

- What is DFM? What is the importance of DFM for PCBA?

- What is Conformal Coating in PCBA?

- What is SMT? How do SMT work on my PCBA?

- What are the benefits of D-MAX's High-Speed SMT Technology for my PCBA?

- What is DIP? How is DIP technology applied in PCBA manufacturing?

- What is the difference between SMT and DIP? How should I choose for my PCBA?

- How is a Turnkey PCBA project quote calculated in D-MAX?

- How does D-MAX handle global electronic component shortages?

- Does the D-MAX PCBA Turnkey process include prototyping?

- During the PCBA design and production process, is there an NDA to protect my IP?

- PCBA 製造商通常提供什麼服務內容?

- 什麼是 Turnkey PCBA 服務?為何重要?

- PCBA 製造商能同時支援打樣與量產嗎?

- 哪些產業最依賴 PCBA 製造服務?

- 選擇可靠 PCBA 製造商時應檢驗哪些認證?

- PCBA 製造商常見的合作模式及選擇指南

- 台灣 PCBA 代工與 Turnkey PCBA 一站式服務|SMT/THT 組裝|DMAX

- Turnkey PCBA 一站式服務|PCBA 代工與 EMS

- PCBA 製造商能同時支援NPI試作與量產嗎?

- PCBA是什麼?

- PCB是什麼?

- D-MAX的Turnkey PCBA提供了哪些服務項目

- PCB跟PCBA的差異是什麼?

- 什麼是 DFM (可製造性設計)?DFM對PCBA的重要性?

- 什麼是三防漆?三防漆在PCBA上的作用是什麼?

- D-MAX 的 SMT 技術,對我的PCBA有什麼好處?

- D-MAX 的高速 SMT 技術,對我的PCBA有什麼好處?

- DIP 是什麼? DIP技術如何應用在 PCBA 的製造?

- SMT (表面貼裝) 和 DIP (通孔) 有什麼不同?我的產品該如何選擇?

- D-MAX Turnkey PCBA 專案的報價是如何計算的?

- D-MAX 如何應對全球性的 PCBA 電子元件缺料?

- D-MAX 的 PCBA Turnkey 製程裡包含打樣嗎?

- PCBA 的設計與生產過程中,有任何保密協議可以保護我的 IP 嗎?

- 台湾のPCBAメーカー|Turnkey PCBA・基板実装(EMS)|SMT/THT|DMAX

- ターンキーPCBAとは|基板実装(EMS)ワンストップの重要性とメリット|DMAX

- DMAX:試作から量産までのワンストップPCBAパートナー(台湾)

RECOMMENDATIONS

News