SMT & DIP Production

Advanced PCB Assembly

SMT & DIP Technologies for High-Performance Electronics

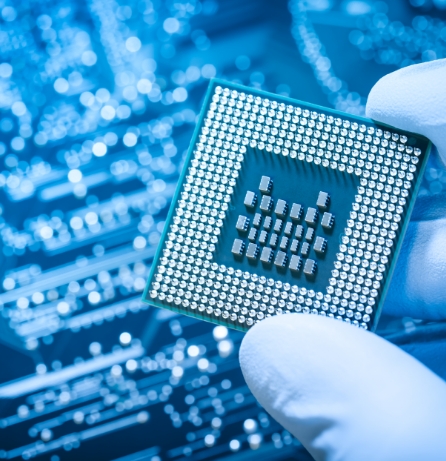

SMT (Surface Mount Technology) and DIP (Dual In-line Package Technology)

are two major assembly technologies in modern electronic component production.

With over 25 years of SMT expertise and 6 advanced SMT production lines, DMax ensures high-performance PCB assembly using both SMT and DIP technologies.

-

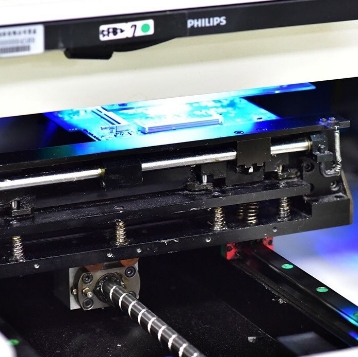

SMT

involves mounting components directly onto the surface of the PCB (Printed Circuit Board), suitable for highly integrated and miniaturized electronic products, offering advantages such as high efficiency and precision.

-

DIP

inserts the component leads into the holes of the PCB, typically applied in larger products or those requiring higher mechanical strength. The combination of both technologies improves product performance and production flexibility.

Advanced SMT Production Lines and Equipment for Superior PCB Assembly

To ensure production efficiency and high quality, the company is equipped with the latest SMT production lines and advanced equipment to support various PCB assembly needs. Key equipment includes:

- High Efficiency Rectifier (Water Cooling)

- Applications: Hardware plating, PCB plating, wastewater treatment

- Control: Pulse Width Modulation (PWM) with IGBT module

- Control Voltage: DC 0-10V

- Advantages: Small size, high efficiency, energy-saving, excellent thermal dissipation, uniform surface plating, environmentally friendly.

- Silicon Control Rectifier (Oil-Water Cooling / Oil Cooling)

- Applications: Hardware plating, copper foil plating, PCB plating, wastewater treatment, anodic treatment, aluminum foil plating, continuous plating

- Control:SCR (Thyristor) control

- Operation:Panel control / Remote control

- Advantages: Low-frequency control, simple structure, solid construction with high acid and alkali resistance, durable.

- Silicon Control Rectifier (Air-Water Cooling / Oil Cooling)

- Applications: Hardware plating, copper foil plating, PCB plating, wastewater treatment, anodic treatment, aluminum foil plating, continuous plating

- Control:Pulse Width Modulation (PWM) with IGBT module

- Operation:Remote control available, can be connected with computers or PLC

- Advantages:IGBT control, stable output, output ripple smaller than 3%, uniform surface plating.

- Switching Power Supply (Air Cooling)

- Applications: Noble metal plating, PCB plating, continuous plating, lab power supply

- Control:Pulse Width Modulation (PWM) with IGBT module

- Advantages:Uniform surface plating, corrosion-resistant design, high precision output.

- Precision Switching Power Supply / Parallel Rectifier

- Applications: Noble metal plating, PCB plating, precious surface plating, terminal continuous plating

- Advantages:High performance, stable output, ideal for high-end noble metal plating processes.

- Controller (RS-485 Communication Interface, DBR Controller)

- Applications: Precise control and communication with other equipment

- Advantages:Supports remote monitoring and management, seamlessly connects with other equipment via RS-485 communication protocol, enabling precise data control.

Cutting-Edge PCBA and PCB Solutions by DMax

Capacity & Quality

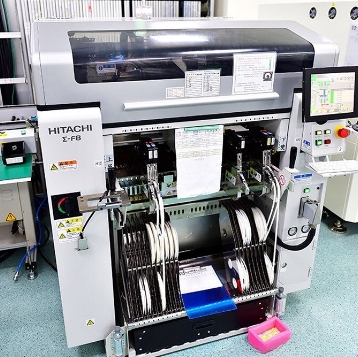

The company operates the latest 6 SMT production lines, aiming to maximize production efficiency and capacity to meet the needs of various PCB assembly requirements.

Daily Capacity

Total of 7,600,000 pieces, sufficient to support large-scale production.

7,600,000+

CONTACTAdvantages

-

High Precision

Advanced equipment and meticulous processes ensure extremely high component mounting accuracy.

-

High Efficiency

Parallel operation of multiple SMT lines significantly boosts production efficiency to meet high-demand orders.

-

Stability

Rigorous quality control processes ensure consistent product quality at every production stage, enhancing the reliability of the final product.

We are committed to providing efficient, stable, and precise SMT and DIP production services to help our customers gain a competitive edge in the market.

Contact US