FAQ

How is a Turnkey PCBA project quote calculated in D-MAX?

How is a Turnkey PCBA project quote calculated?

This is one of the most critical business questions in B2B purchasing decisions. D-MAX is committed to providing "transparent and complete" Turnkey quotations. We don't just quote a vague "total price"; we provide "a comprehensive service ledger that integrates engineering, procurement, manufacturing, and risk management."

First, you must understand the fundamental difference between a Turnkey quote and a "Consignment" quote:

Consignment Quote: Appears cheap, but the quote "only" includes the "assembly labor fee." You (the customer) must personally bear all "hidden costs," including: procurement manpower, component inventory pressure, scrap losses from material errors, and the "line-down costs" caused by part shortages.

Turnkey Quote: This is a "Total Cost of Ownership (TCO)" quotation. It transforms all the hidden costs and risks mentioned above into D-MAX's professional "supply chain management service," making your procurement costs "fully controllable and predictable."

The Four Core Components of a Turnkey Quote

D-MAX's Turnkey PCBA quotation is accurately calculated based on the following four main components:

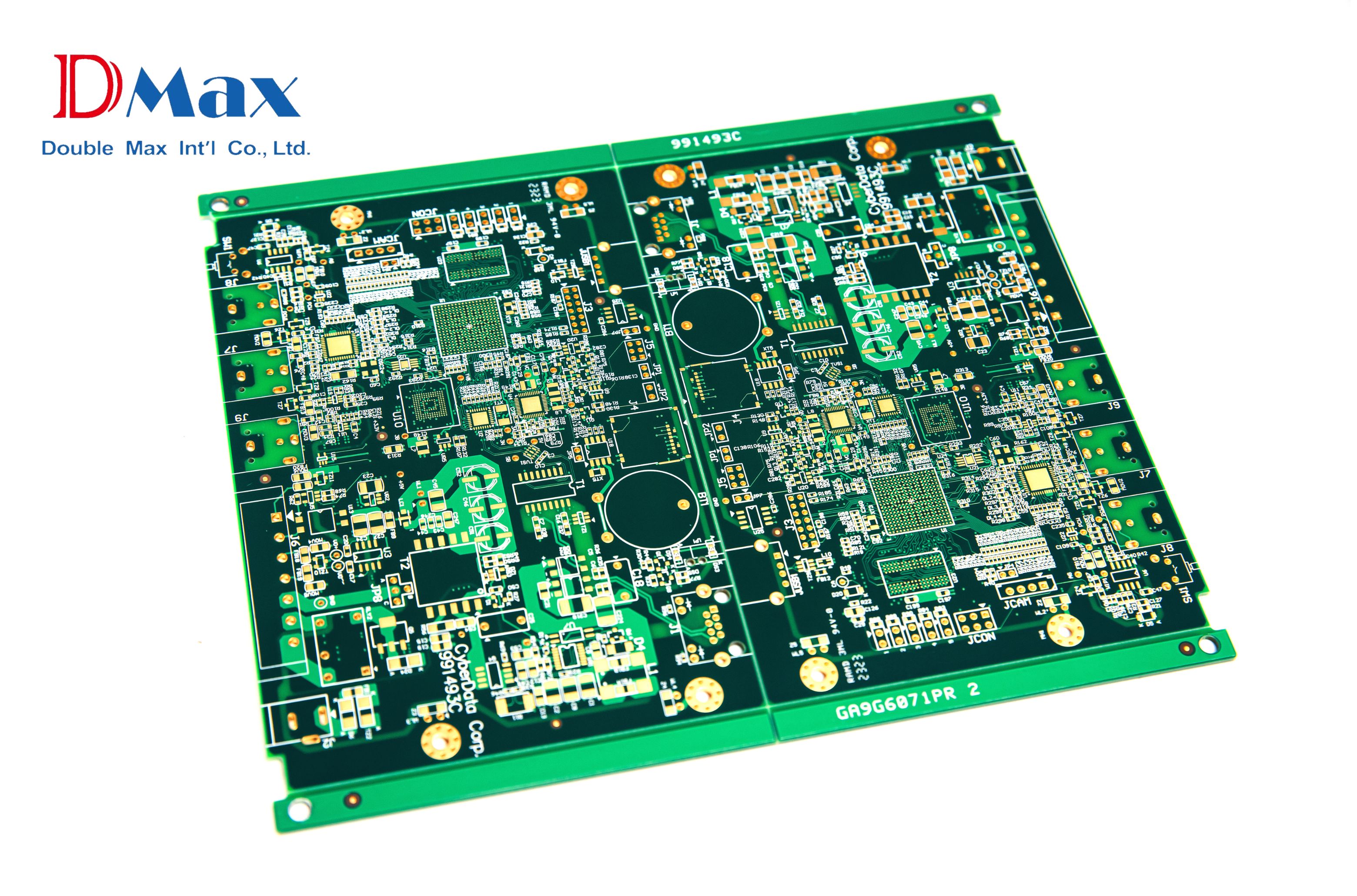

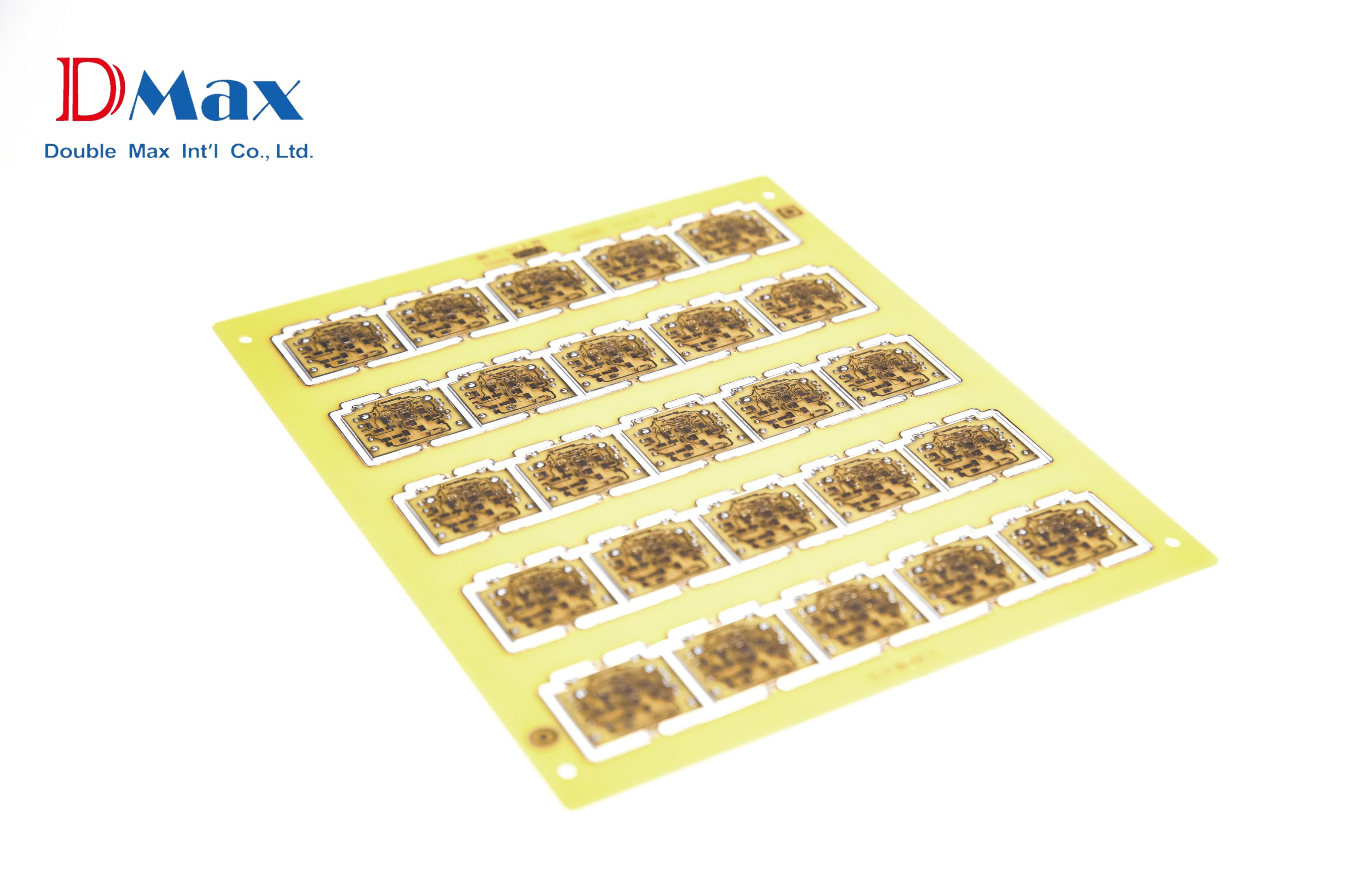

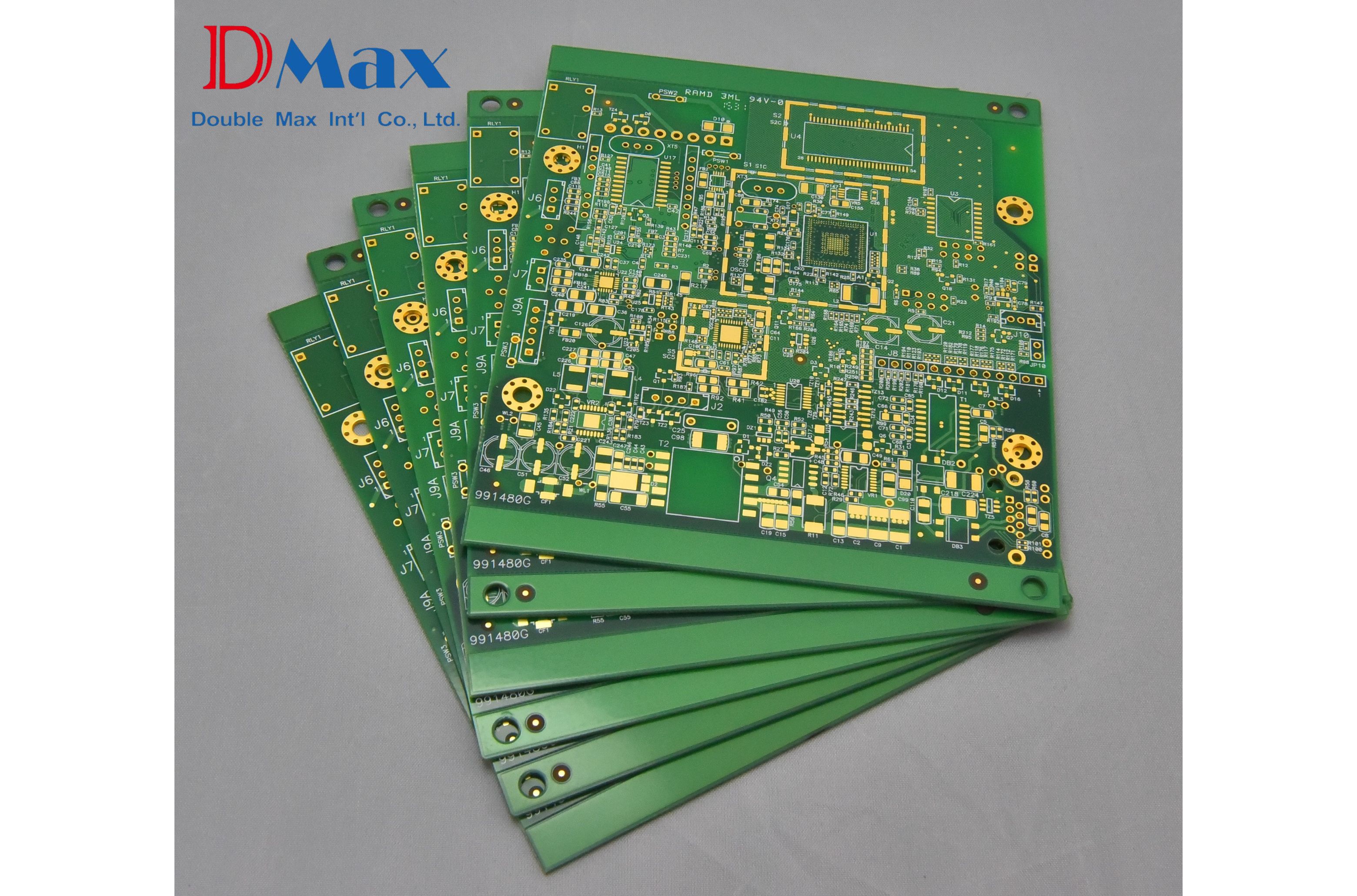

1. PCB Fabrication Cost

Basis of Calculation: This is the cost of manufacturing the "foundation." The price depends on the specifications in your Gerber files, including:

Layer Count: 2-layer, 4-layer, 8-layer, etc. (more layers = higher cost).

Material: Standard FR-4, high-frequency materials, Rigid-Flex, etc.

Process: Min. trace/space, surface finish (e.g., ENIG), solder mask color.

Quantity: Your order volume (higher volume = lower amortized unit cost).

2. BOM Component Cost

Basis of Calculation: This is the highest-percentage and most complex part of a Turnkey quote.

Component Cost: We will quote 100% according to the "specified Manufacturer Part Numbers (MPN)" and quantity on your BOM list, sourcing from global authorized distributors.

Sourcing Fee: This is a reasonable management fee. It "includes" the "service value" of D-MAX's professional procurement team performing "global price comparison," "lead time coordination," "Incoming Quality Control (IQC)," "counterfeit detection," "kitting," and "assuming the risk of part shortages" on your behalf.

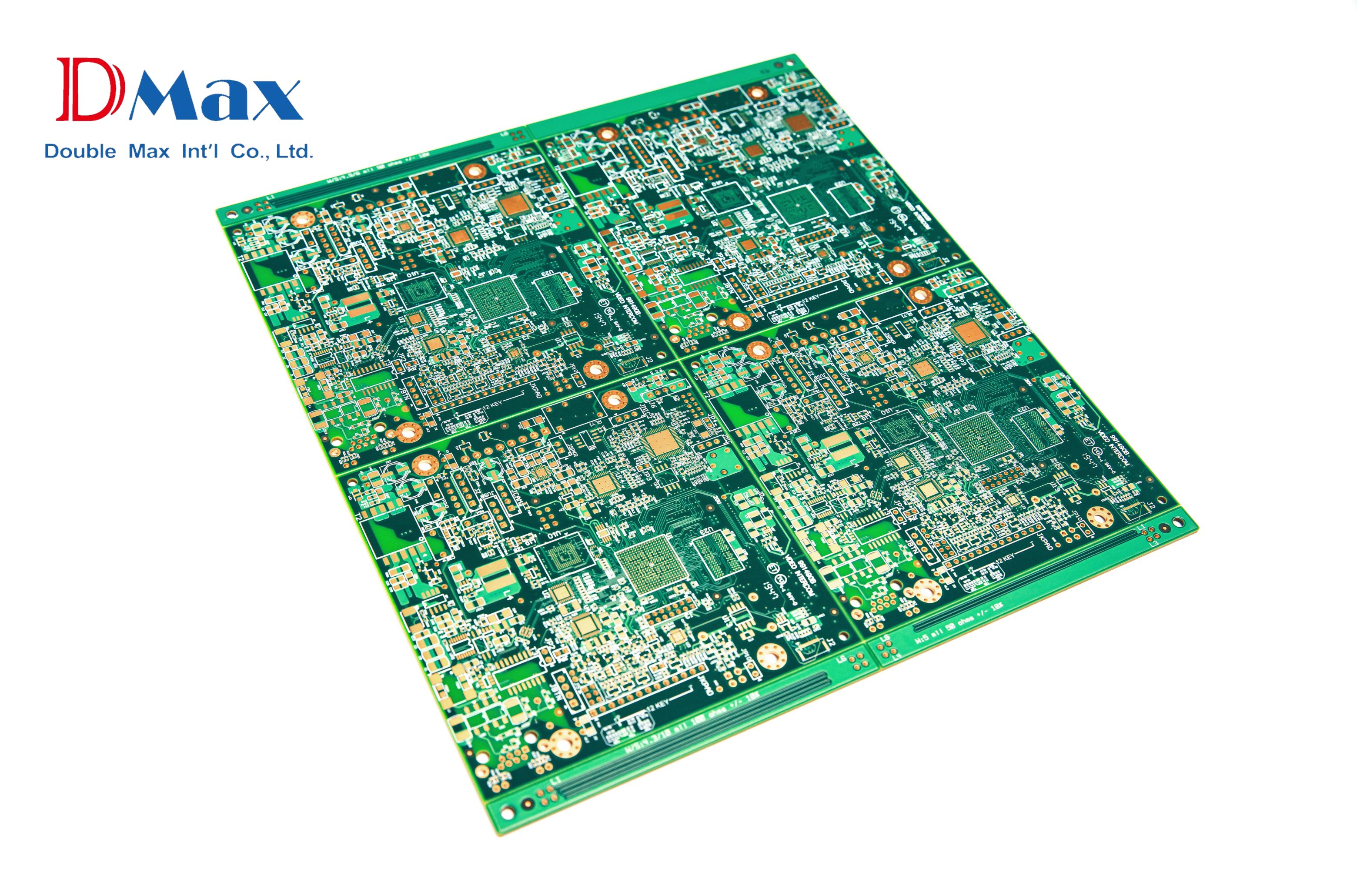

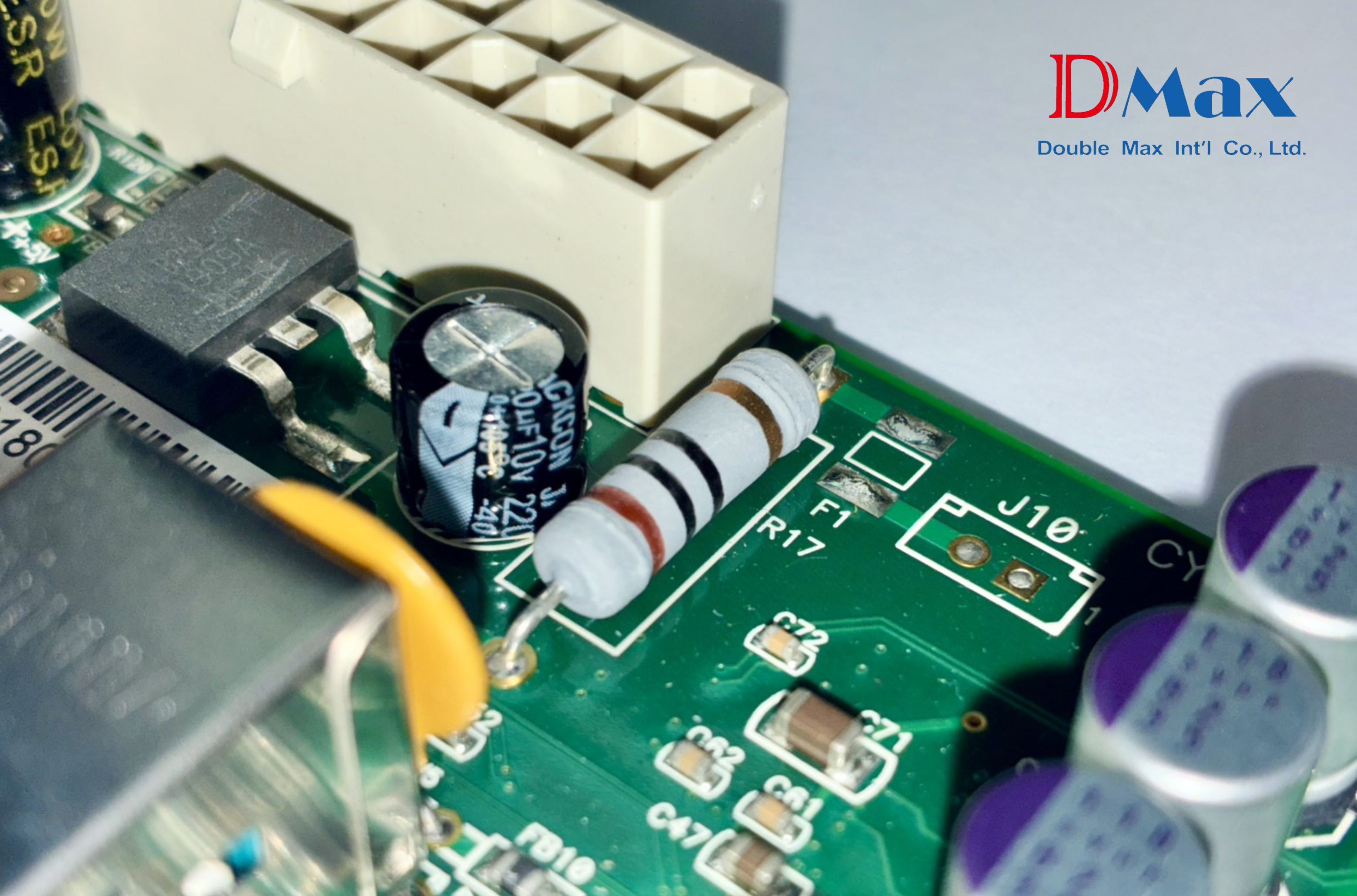

3. Assembly & Process Cost

Basis of Calculation: This is the "process fee" for combining the "foundation" and the "components."

SMT Placement Fee: Calculated based on the number of SMT component "points" (one point = one solder pad). The more SMT points, or the more precise (e.g., BGA, 01005), the higher the fee.

DIP Insertion Fee: Calculated based on the number of DIP component "pins" and the "manual insertion labor time."

Process Complexity: For example, does it require "double-sided SMT" (needs two reflow passes), "selective wave soldering," or "Conformal Coating"?

4. Testing & NRE (Non-Recurring Engineering) Cost

NRE (One-Time Engineering Fee): This is a one-time fee, including:

SMT Stencil Fee: The custom stencil used for printing solder paste.

Fixture Fee: Such as a "wave solder carrier" or "functional testing fixture."

Testing Fee:

AOI / X-Ray Inspection: D-MAX typically includes this as a "standard QC process" within the assembly fee.

FCT (Functional Testing): If you require us to perform 100% functional testing, we will quote based on the "labor time" required by the "Test SOP" you provide.

The "Value-Add" of a D-MAX Quote: More Than Just a Price, It's a DFM Analysis

D-MAX's Turnkey quote is not just a "sum of BOM prices."

When you submit your BOM and Gerber files to us, our "Quotation Process" and "DFM Analysis Process" are "activated simultaneously":

1. DFM Feedback:

As our engineers prepare the quote, they may proactively inform you: "The footprint design on your PCB does not match component A on your BOM; modification is recommended." This avoids costly rework at the quotation stage.

2. DFS (Design for Sourcing) Recommendations:

During quoting, our procurement team will proactively analyze the "supply chain health" of your BOM.

For example: "Component B you specified is EOL (End-of-Life); we recommend switching to model C."

Or: "Component D you specified has a 52-week lead time and is expensive. We found a 100% compatible substitute E with an 8-week lead time and 30% lower cost. Would you like to consider it?"

A Turnkey quotation from D-MAX is not just a PCBA cost list; it is a professional DFM/DFS diagnostic report to help you complete your product's production and manufacturing smoothly.

Our commitment to a "transparent" quote is to ensure you know exactly where every cent goes. Our proactive "engineering recommendations" are to maximize the reduction of your Total Cost of Ownership (TCO) before the project even begins.

- What is the difference between SMT and DIP? How should I choose for my PCBA?

- How does D-MAX handle global electronic component shortages?

RECOMMENDATIONS

_2_cover.png)

_cover.png)