FAQ

What is the difference between SMT and DIP? How should I choose for my PCBA?

What is the difference between SMT and DIP? How should I choose for my PCBA?

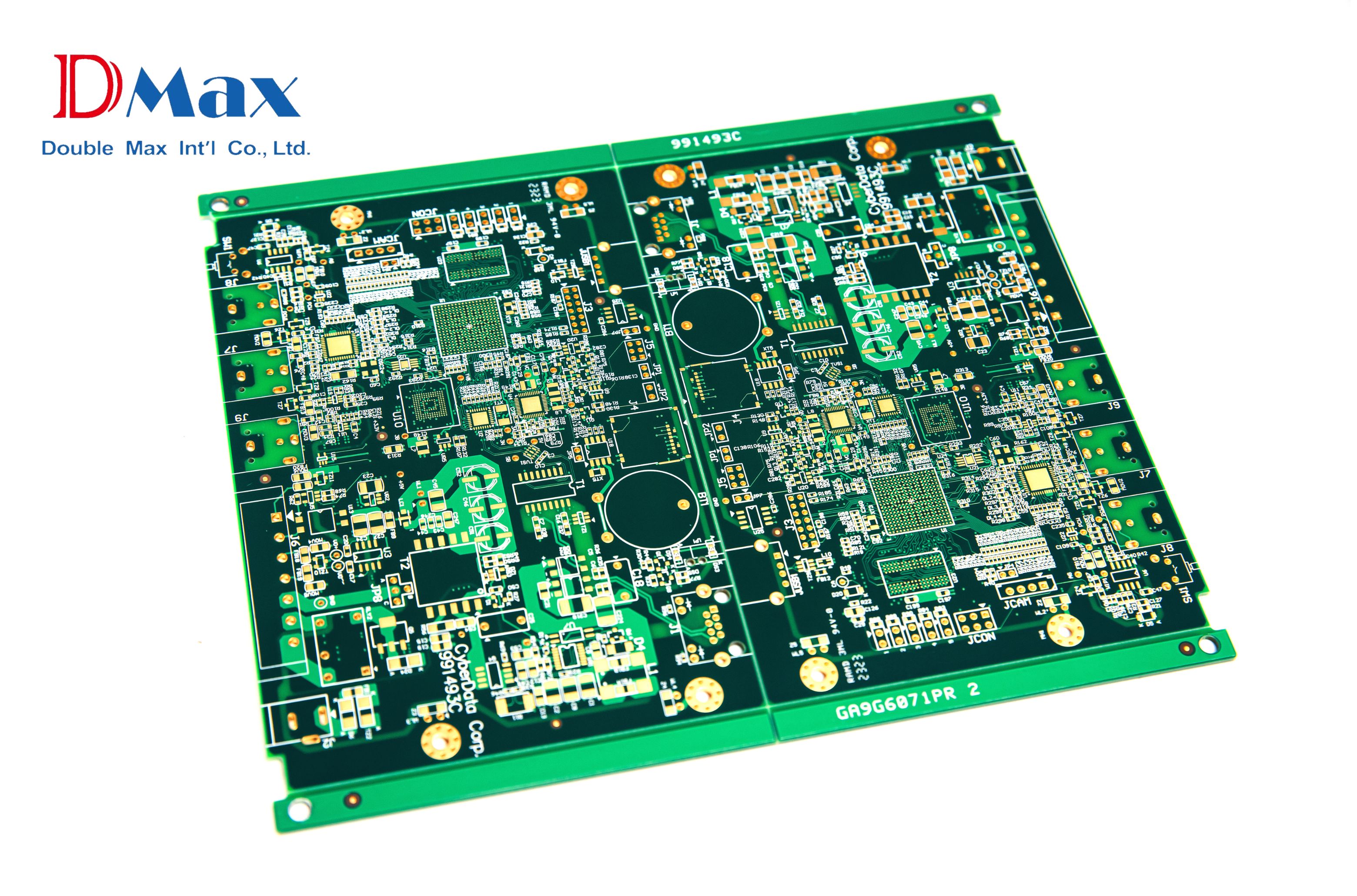

SMT (Surface-Mount Technology) and DIP (Dual In-line Package / insertion technology) are the two core assembly processes that make up a PCBA (Printed Circuit Board Assembly).

Simply put, their key difference lies in "how the PCBA components are installed on the PCB":

- SMT (Surface-Mount Technology):

Involves "mounting" components onto the surface of the PCB.

- DIP (Insertion Technology):

Involves "inserting" component leads "through" the PCB's through-holes.

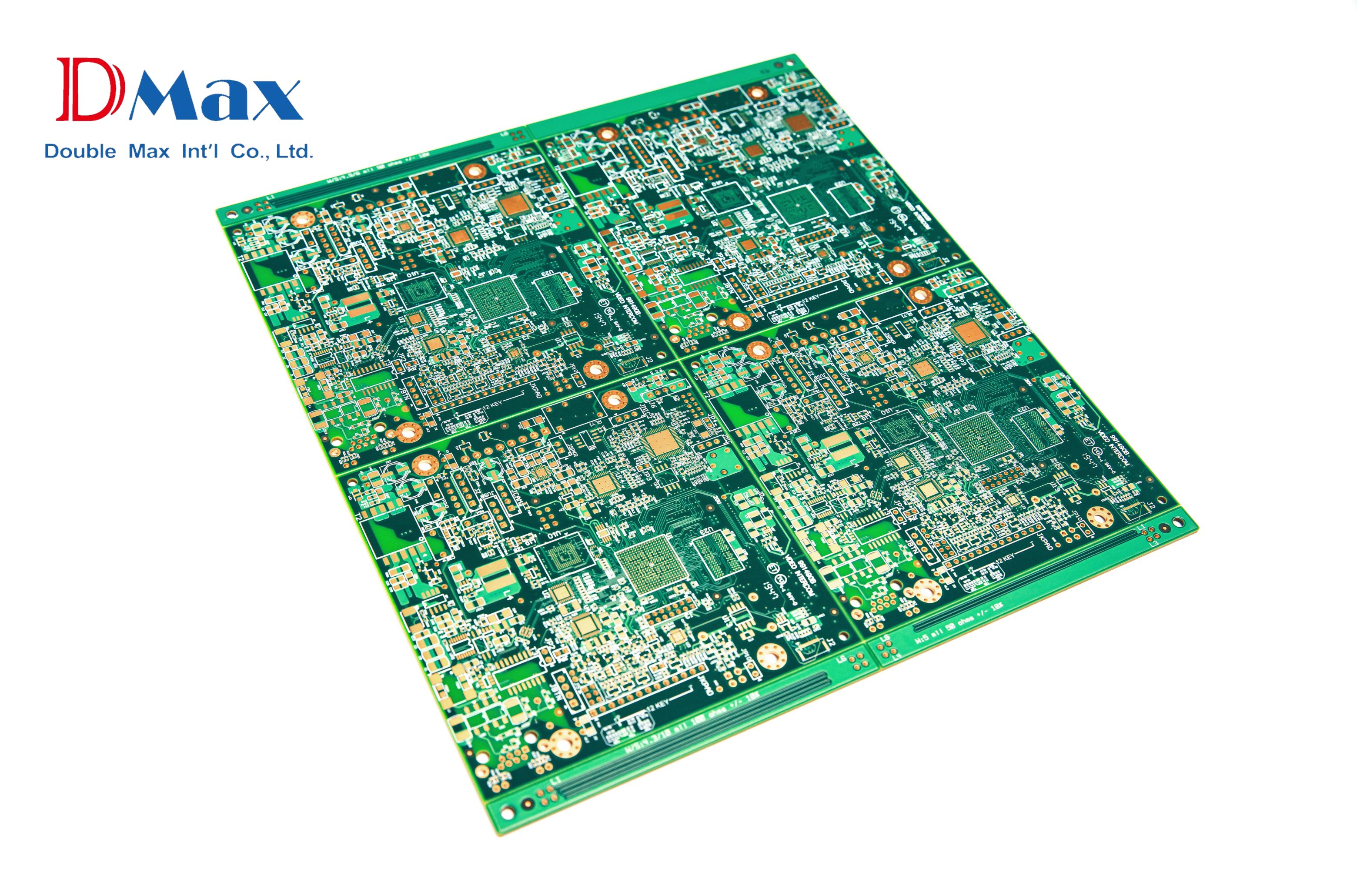

In modern electronics manufacturing, you rarely need to "choose one or the other." 99% of modern PCBAs use "Mixed-Technology," meaning both SMT and DIP components exist on the same board.

Your (the customer's) "product design" determines which components must use SMT and which must use DIP. D-MAX's expertise lies in perfectly mastering these two distinct processes and integrating them onto a single PCBA.

SMT (Surface-Mount Technology) - The Representative of "Precision" & "Density"

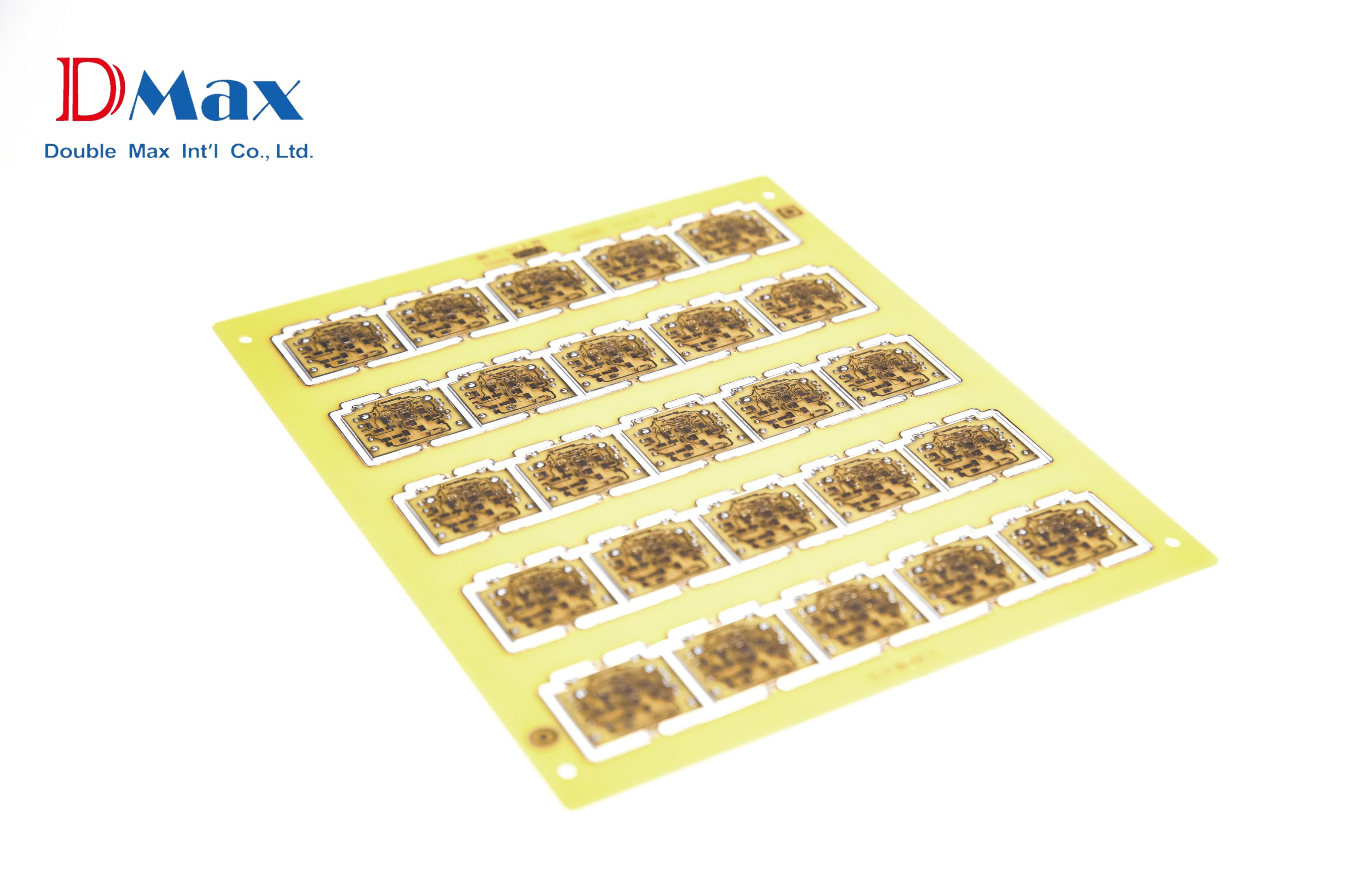

Core Concept: Precisely "placing" tiny, leadless components (called SMDs) onto the solder pads on the PCB's surface.

Soldering Method: Solder paste is printed first, then a "Reflow Oven" is used for high-heat soldering, attaching the components to the same side of the PCB surface.

Key Advantages:

Extreme Miniaturization: Components can be as small as a grain of sand (e.g., 01005).

- High-Density: Components can be mounted on both sides of the board for an extremely dense layout.

- Good High-Frequency Performance: Extremely short leads minimize signal interference, making it the only choice for high-speed computing (like CPUs, 5G).

- Full Automation: Produced via "High-Speed SMT Pick-and-Place Machines" for fast, low-cost, and consistent quality.

DIP (Insertion Technology / THT) - The Representative of "Strength" & "Stability"

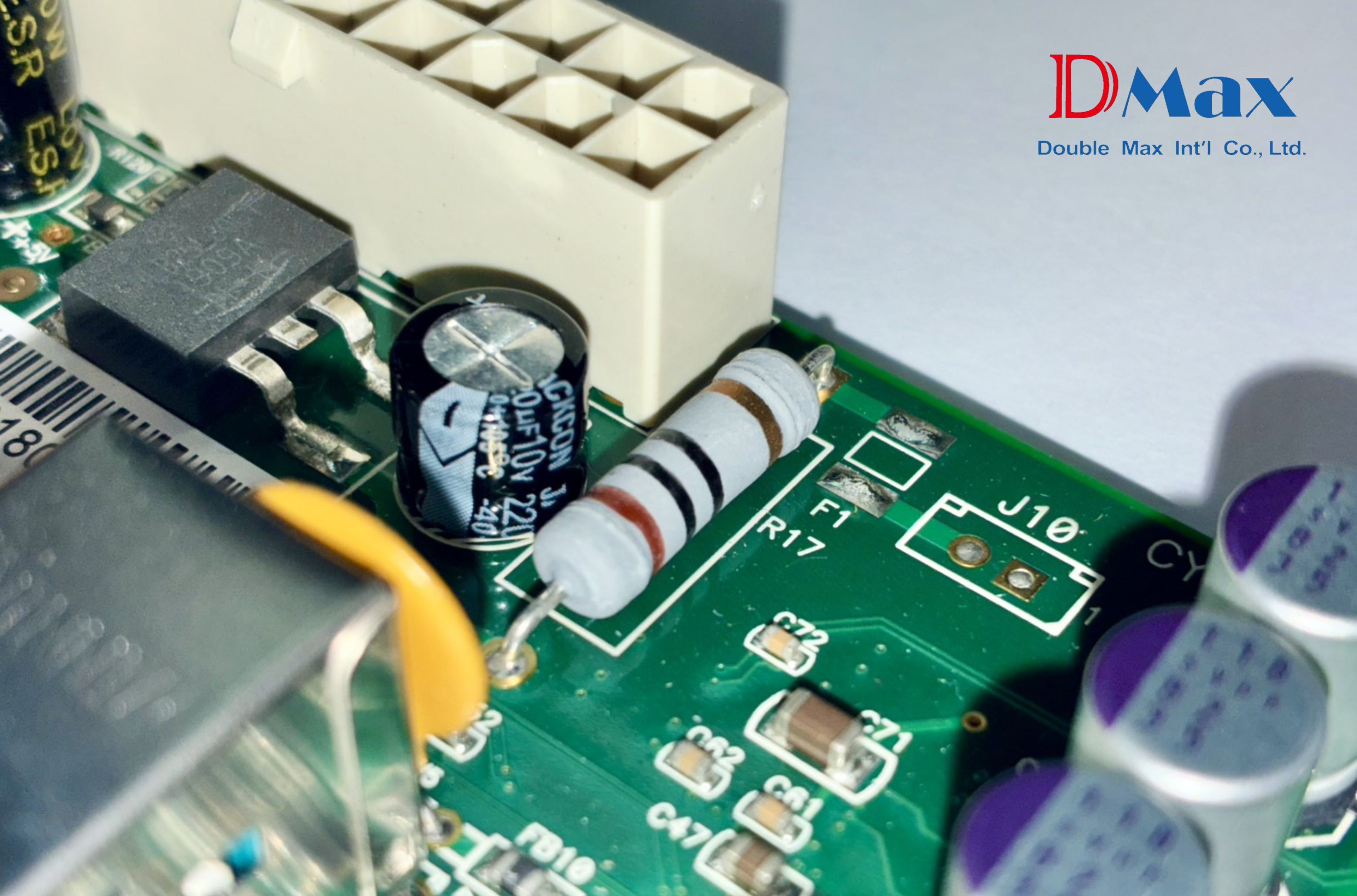

Core Concept: "Inserting" components that have long metal "leads" (legs) "through" pre-drilled "through-holes" on the PCB.

Soldering Method: Components are secured on the other side of the PCB via "Wave Soldering" or "manual soldering."

Key Advantages:

Extreme Mechanical Strength: Component leads pass through the PCB, making solder joints as strong as tree roots, able to withstand strong external forces, stress, and vibration.

- High Power/Heat Tolerance: Robust leads and the through-hole structure can conduct large currents and effectively dissipate heat.

- Durability: Ideal for components that require long-term reliable operation or exist in harsh environments.

How should I choose for my product? (D-MAX's Professional Advice)

You don't have to worry about choosing; your "product function" has already decided for you.

When D-MAX's DFM (Design for Manufacturability) engineers review your BOM list, they will automatically classify this for you. The component selection logic on a PCBA is as follows:

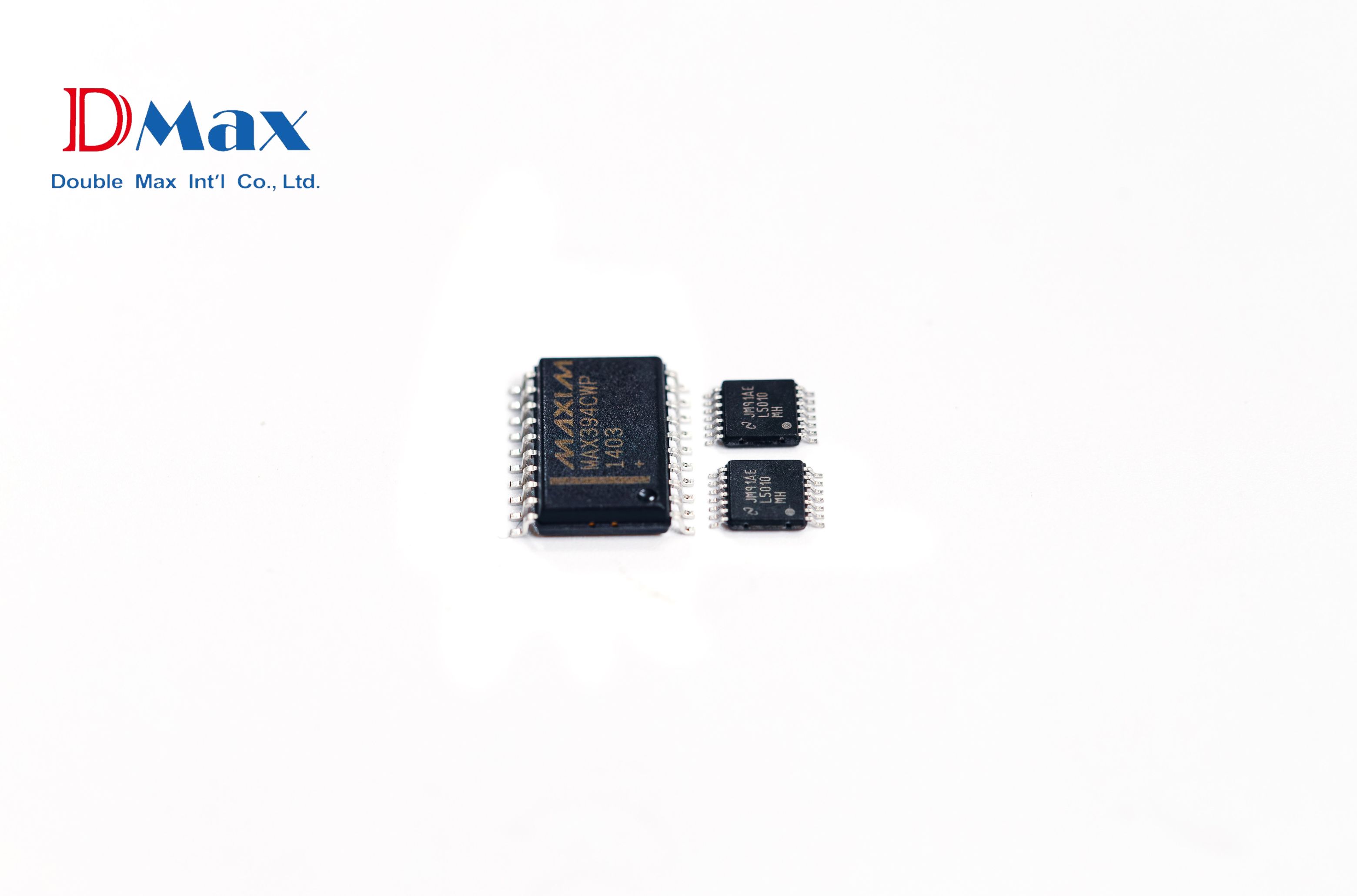

1. Your Product's "Brain" & "Nerves": Always use SMT

Examples: Main processors (CPU/MCU), chipsets (BGA/QFN), memory (RAM), and the vast majority of passive components (resistors, capacitors).

Reason: These are the "functional core" of the product. They require high-speed computation, high-density layouts, and must be extremely miniaturized. SMT is the only way to achieve these functions.

2. Your Product's "Joints" & "Heart": Must use DIP

Examples:

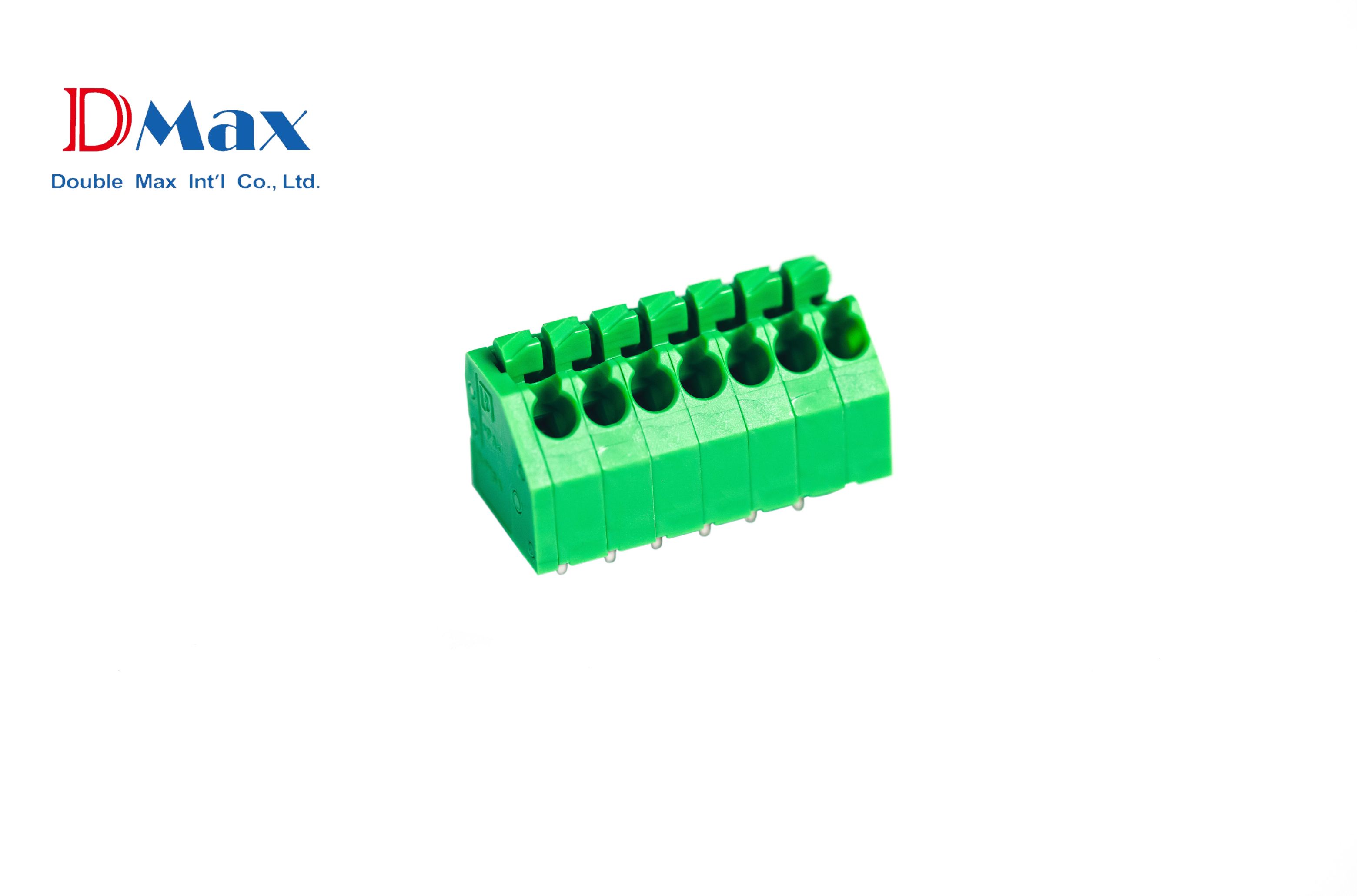

I/O Connectors: USB, HDMI, RJ45 (network) ports, power sockets.

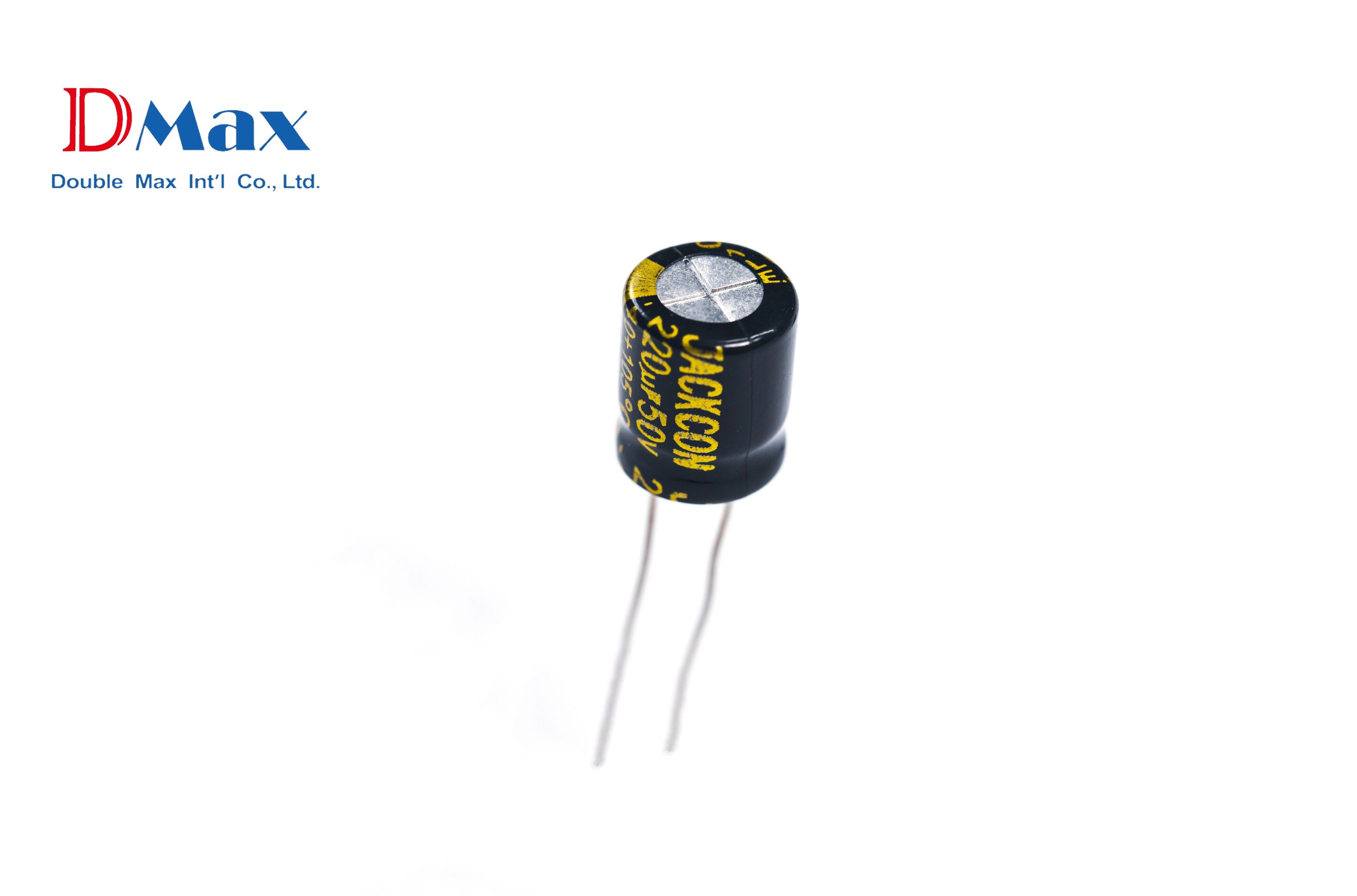

High-Power Components: Large electrolytic capacitors, transformers, power transistors.

Reason:

"Connectors" must withstand daily user "plugging/unplugging" and "physical torsion." The strength of an SMT solder joint is absolutely insufficient; only DIP insertion can guarantee it will not come loose.

"High-power components" are bulky and heavy, requiring the physical support of a DIP structure, and they use their robust leads to conduct large currents and dissipate heat.

How does D-MAX master "Mixed-Technology"?

The Challenge: On a single PCBA, how do you perform SMT (reflow) first, then DIP (wave solder), without letting the second round of high heat "damage" the results of the first?

This is D-MAX's core expertise.

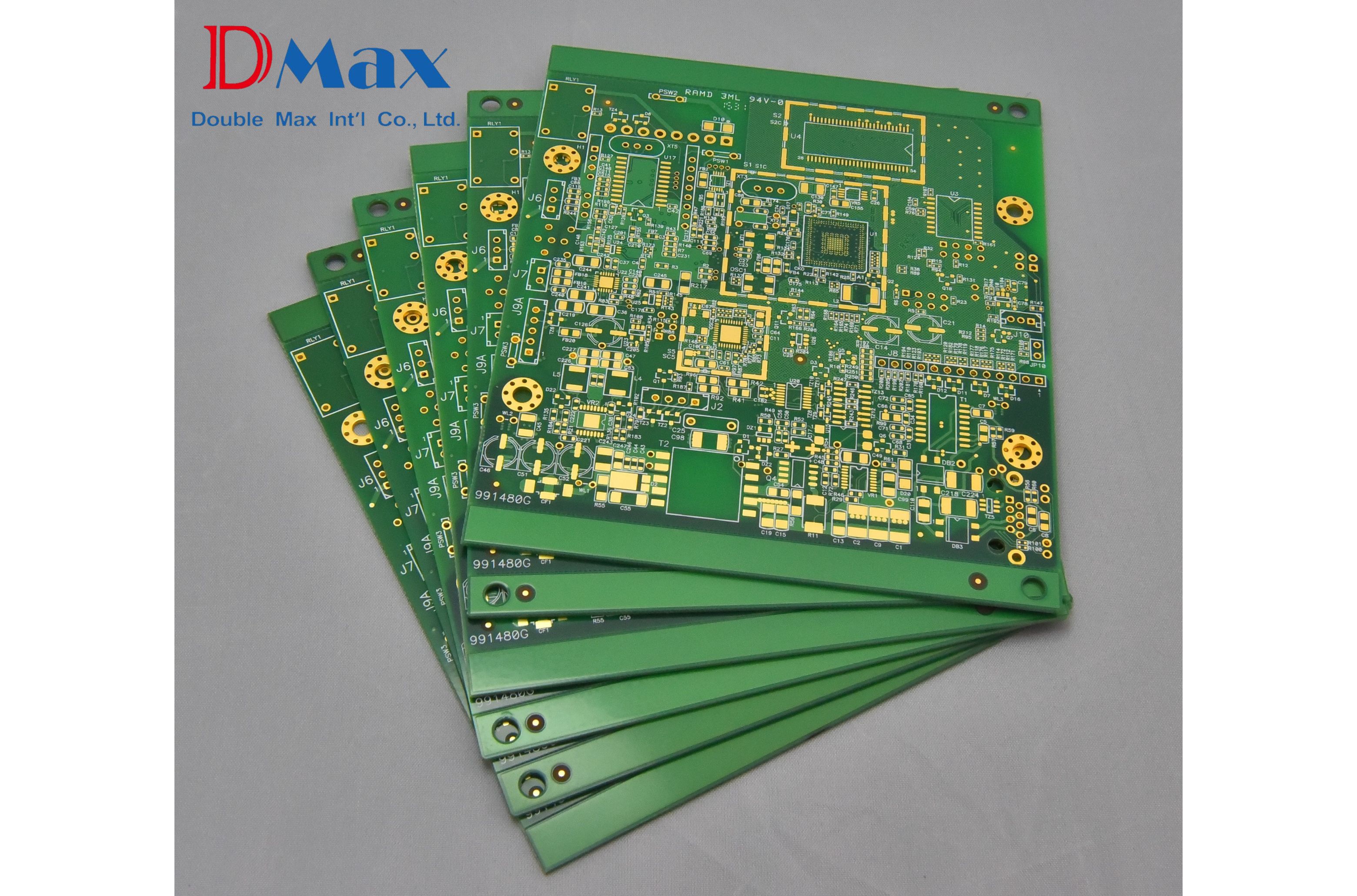

Rigorous DFM Analysis:

Before production, our DFM team inspects your PCBA design and layout. D-MAX ensures that the DIP component holes are not too close to SMT components (especially BGAs), preventing the SMT parts from being damaged during the second pass over the high-temperature wave solder.

Customized "Wave Solder Carrier":

This is our key technology. D-MAX's engineers will design a specialized "carrier" (fixture) for your PCBA. This carrier precisely shields all SMT areas that do not need to be soldered, exposing only the DIP leads.

Precise Process Control:

The carrier moves the PCBA through the wave solder at a precisely calculated speed and temperature. The solder wave only contacts the DIP leads it is supposed to, while the SMT areas remain perfectly protected by the carrier.

SMT is responsible for your product's "precision" and "function"; DIP is responsible for your product's "durability" and "strength."

Through rigorous DFM engineering and precise mixed-technology process control, D-MAX perfectly combines the "high density" of SMT with the "high strength" of DIP on a single PCBA, providing you with a 100% reliable, fully functional Turnkey service.

- What is DIP? How is DIP technology applied in PCBA manufacturing?

- How is a Turnkey PCBA project quote calculated in D-MAX?

RECOMMENDATIONS

_2_cover.png)

_cover.png)