FAQ

What does a PCBA manufacturer typically provide?

What does a PCBA manufacturer typically provide?

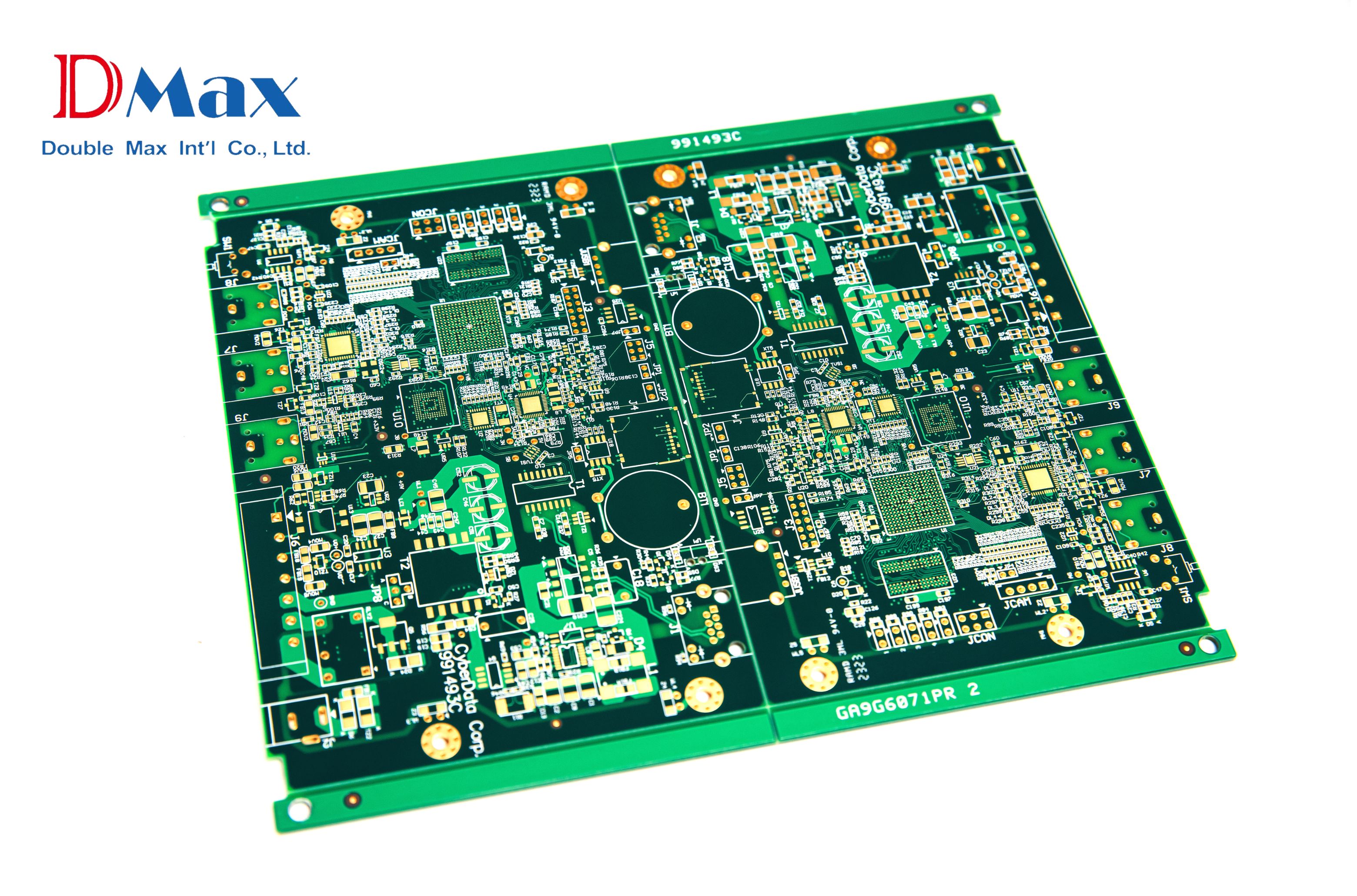

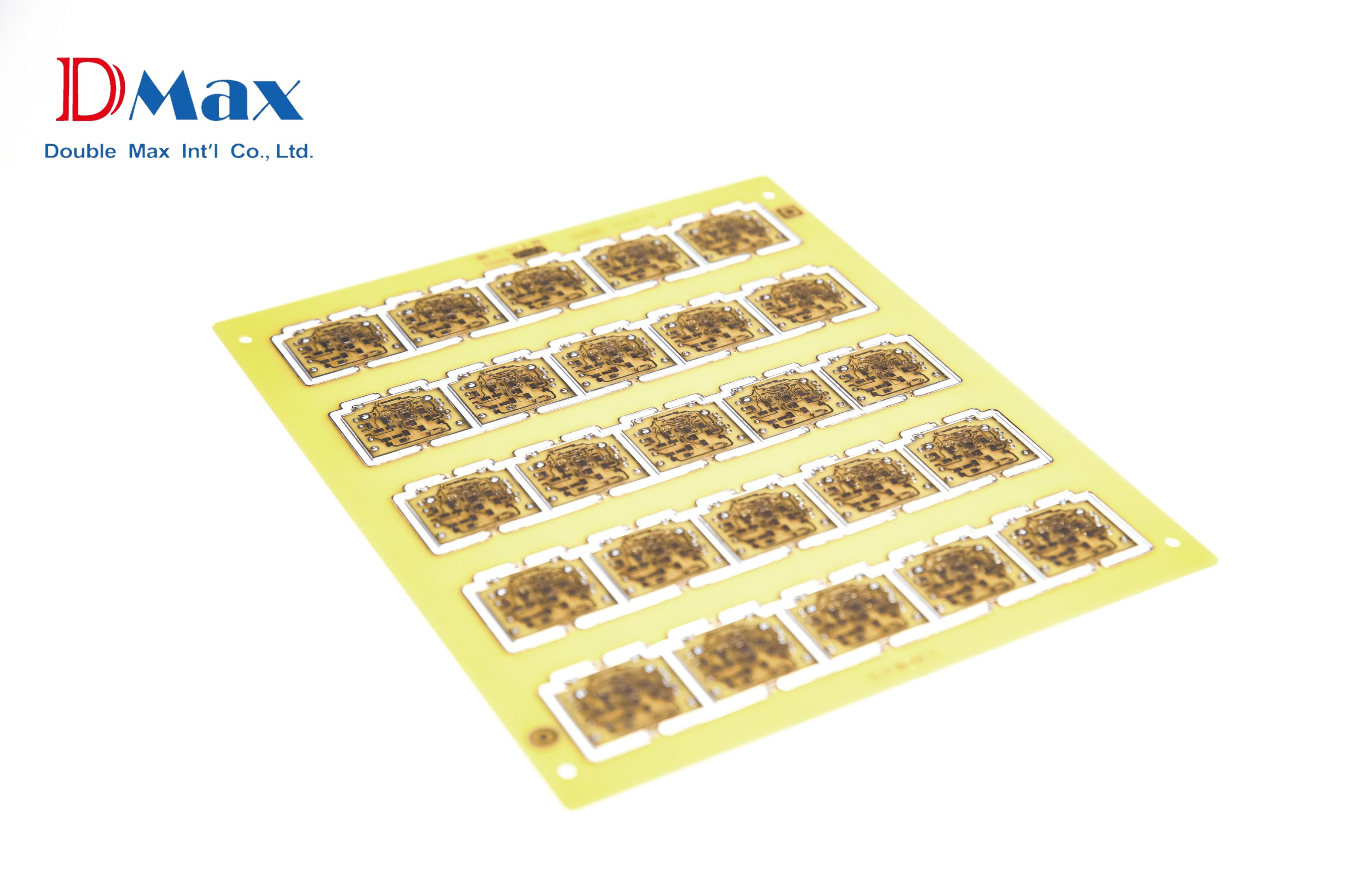

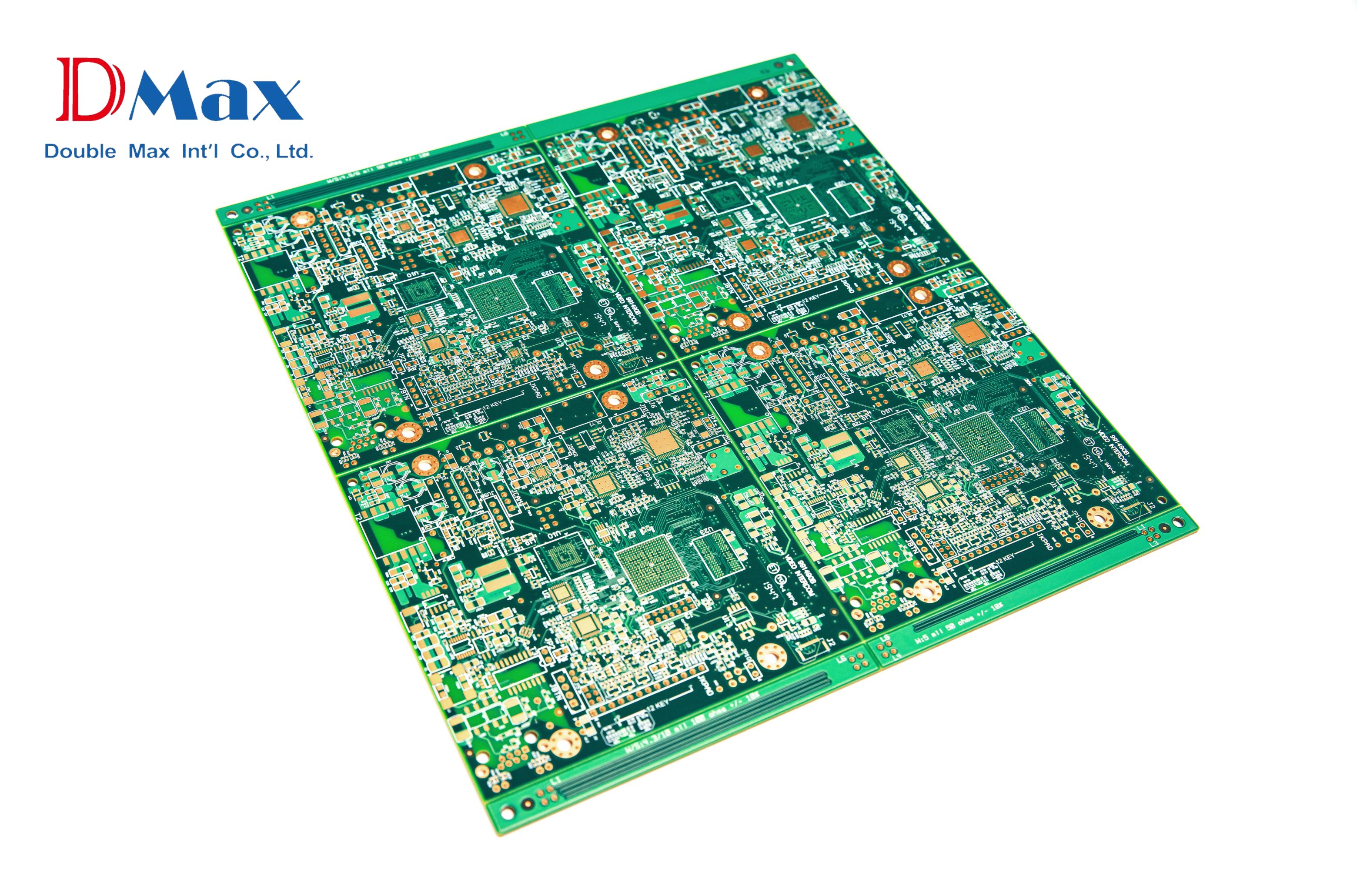

Complete PCBA Manufacturing Services

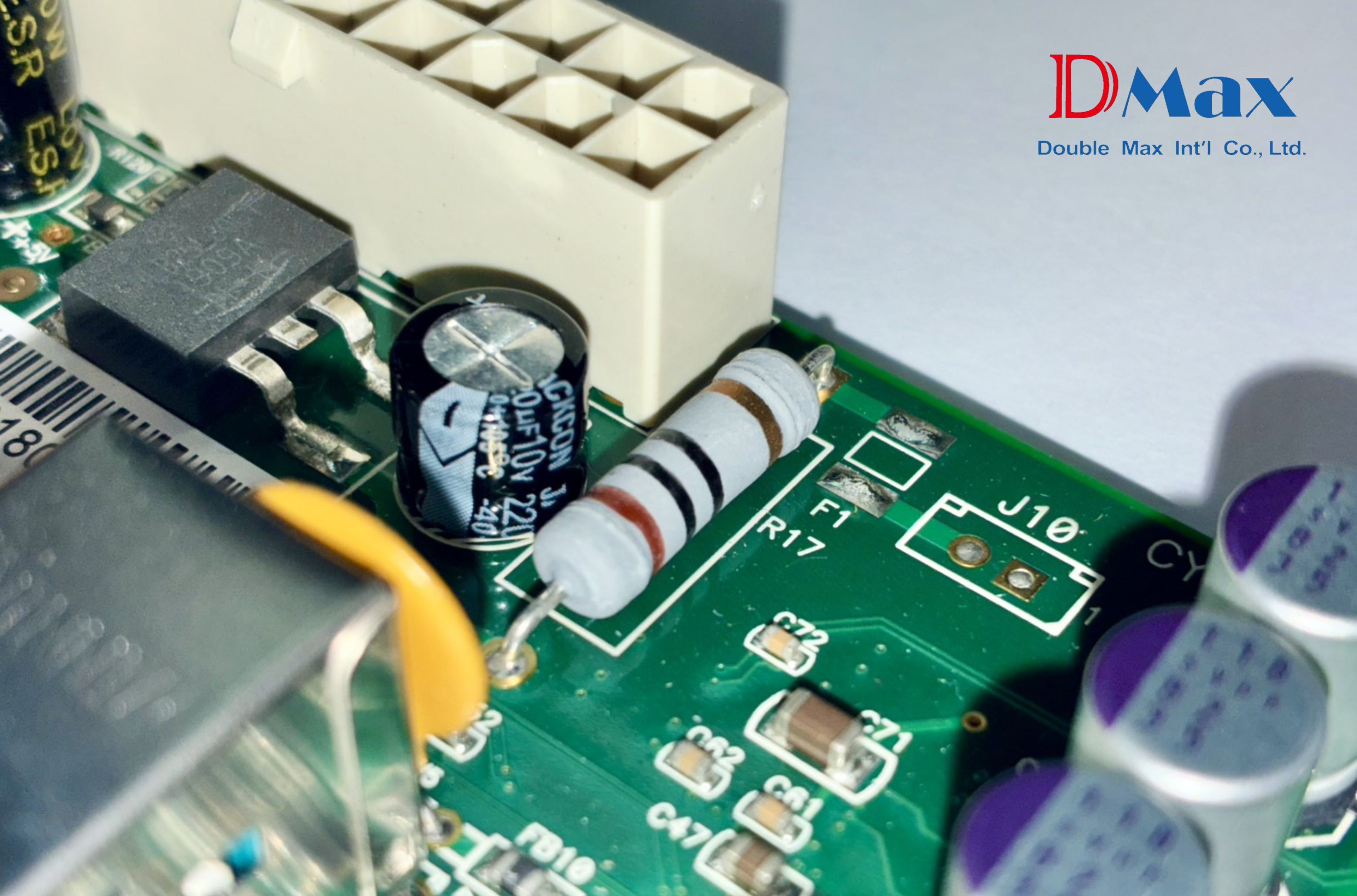

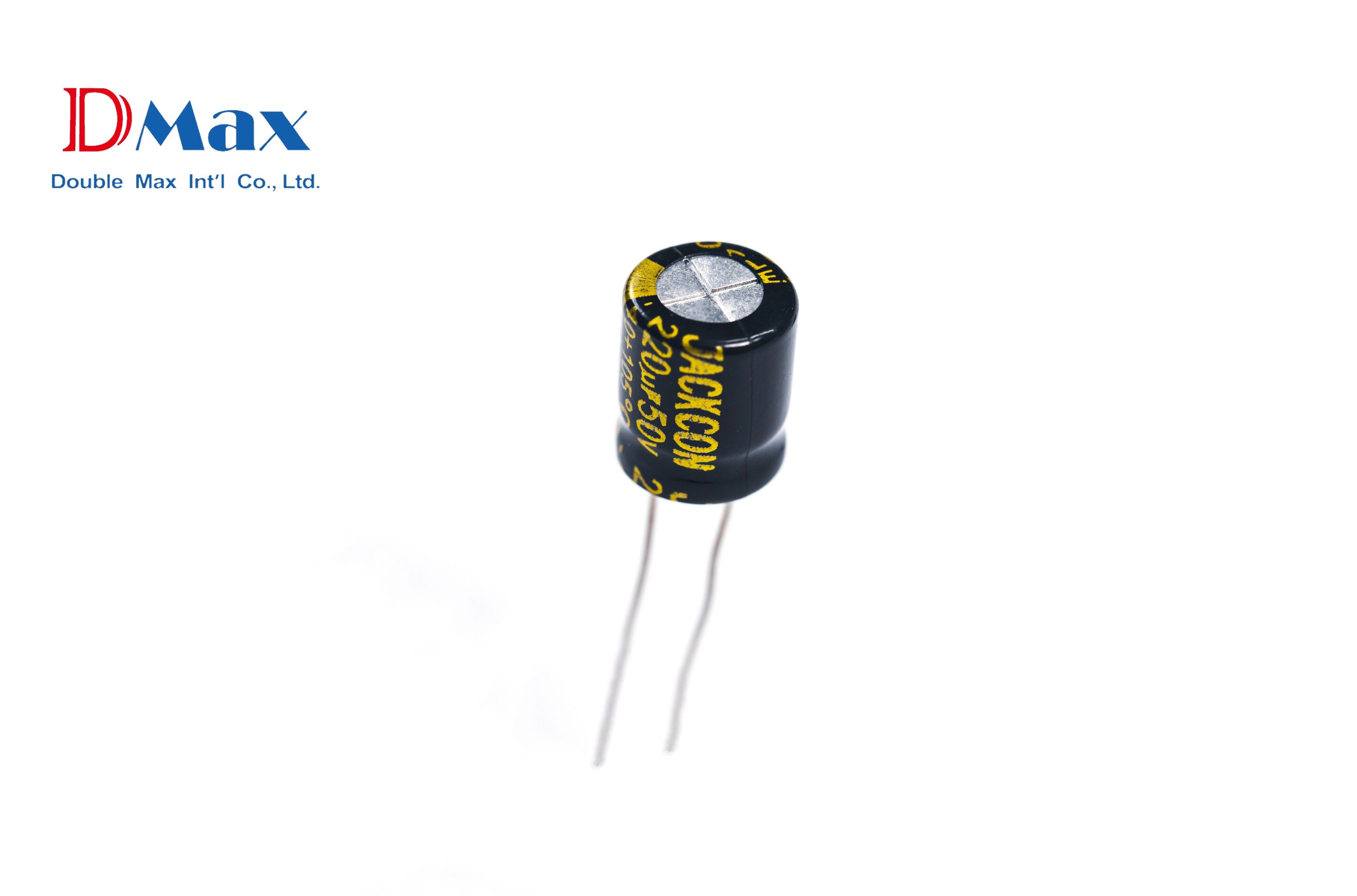

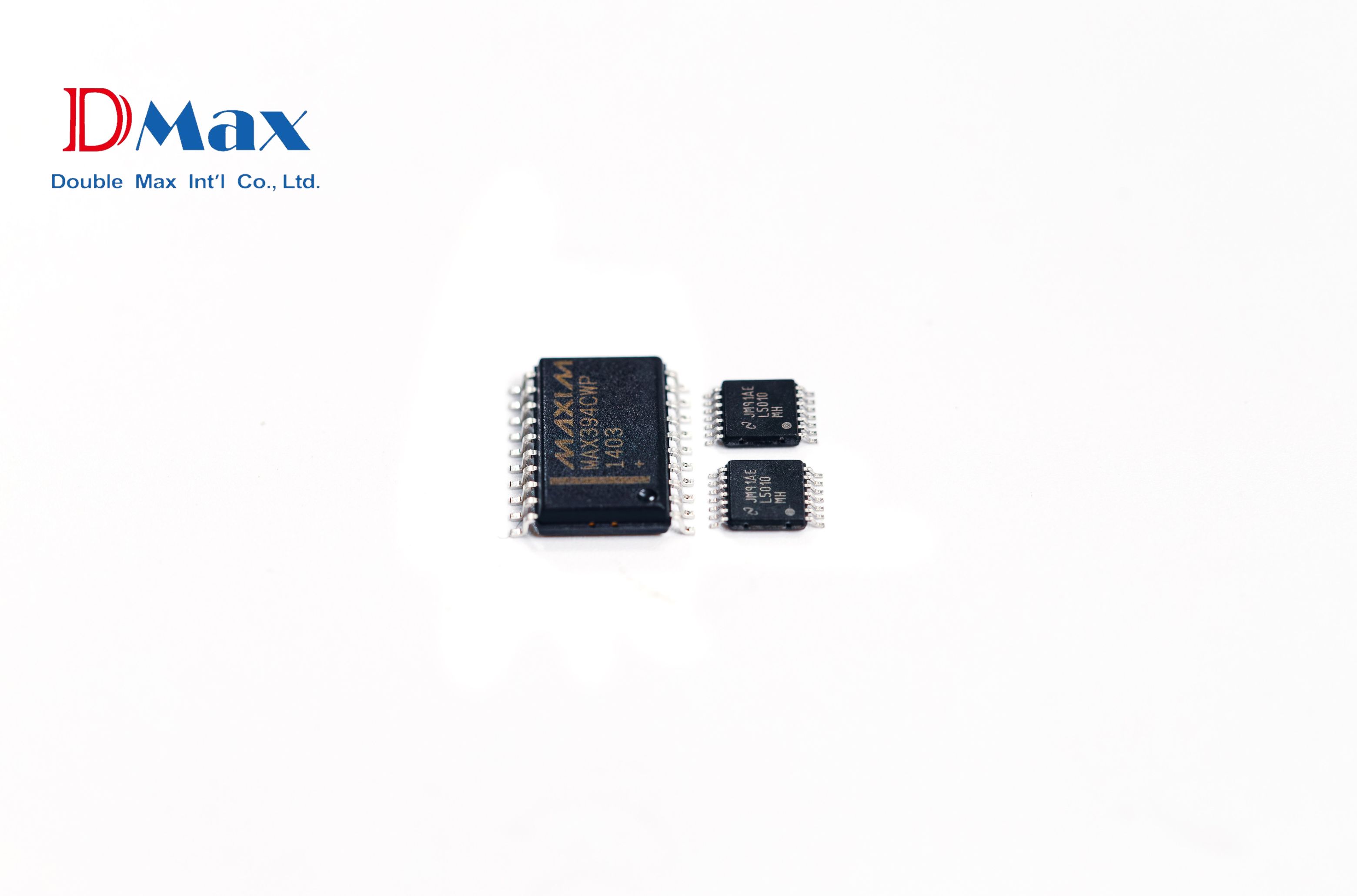

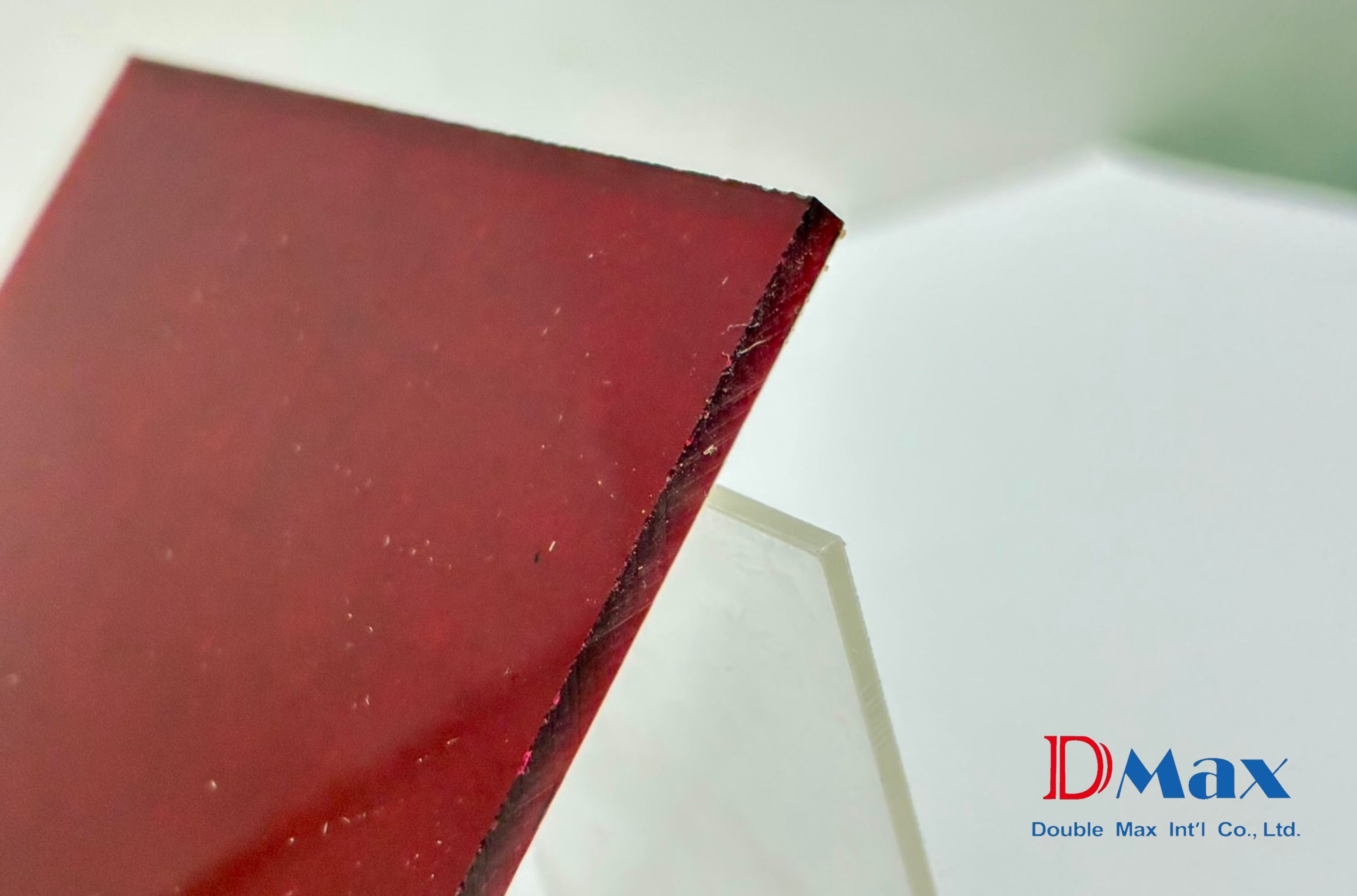

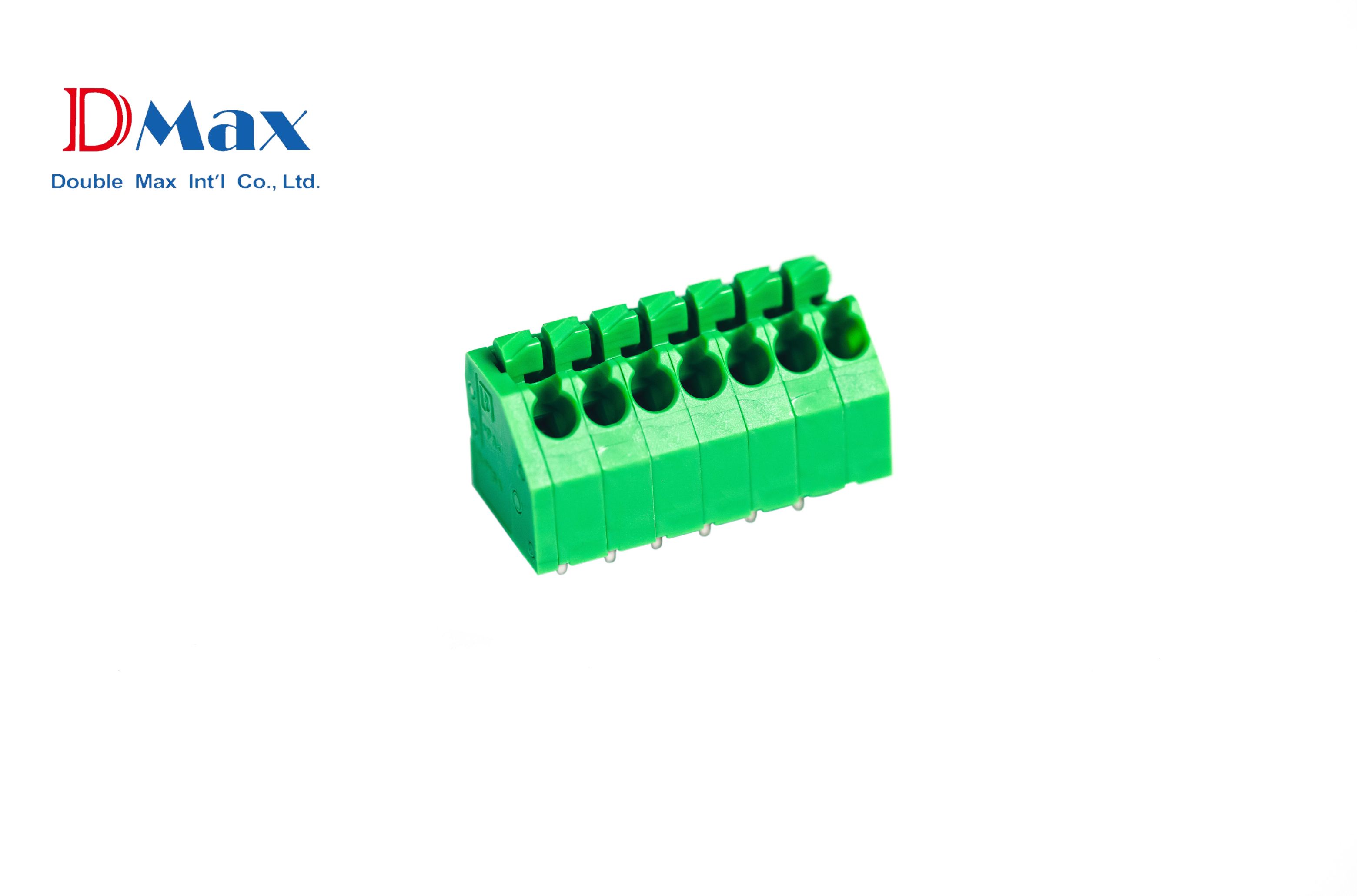

A professional PCBA manufacturer typically offers end-to-end Printed Circuit Board Assembly (PCBA) services, covering every stage of the electronics manufacturing process. PCBA manufacturer services include PCB fabrication or procurement, electronic component sourcing, SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly, optical and electrical inspections, and final packaging and shipping.

A capable PCBA manufacturer plays a critical role in turning product concepts into reliable, manufacturable electronics by managing both the technical and operational aspects of assembly.

🔹 Flexible Support for Prototyping and Mass Production

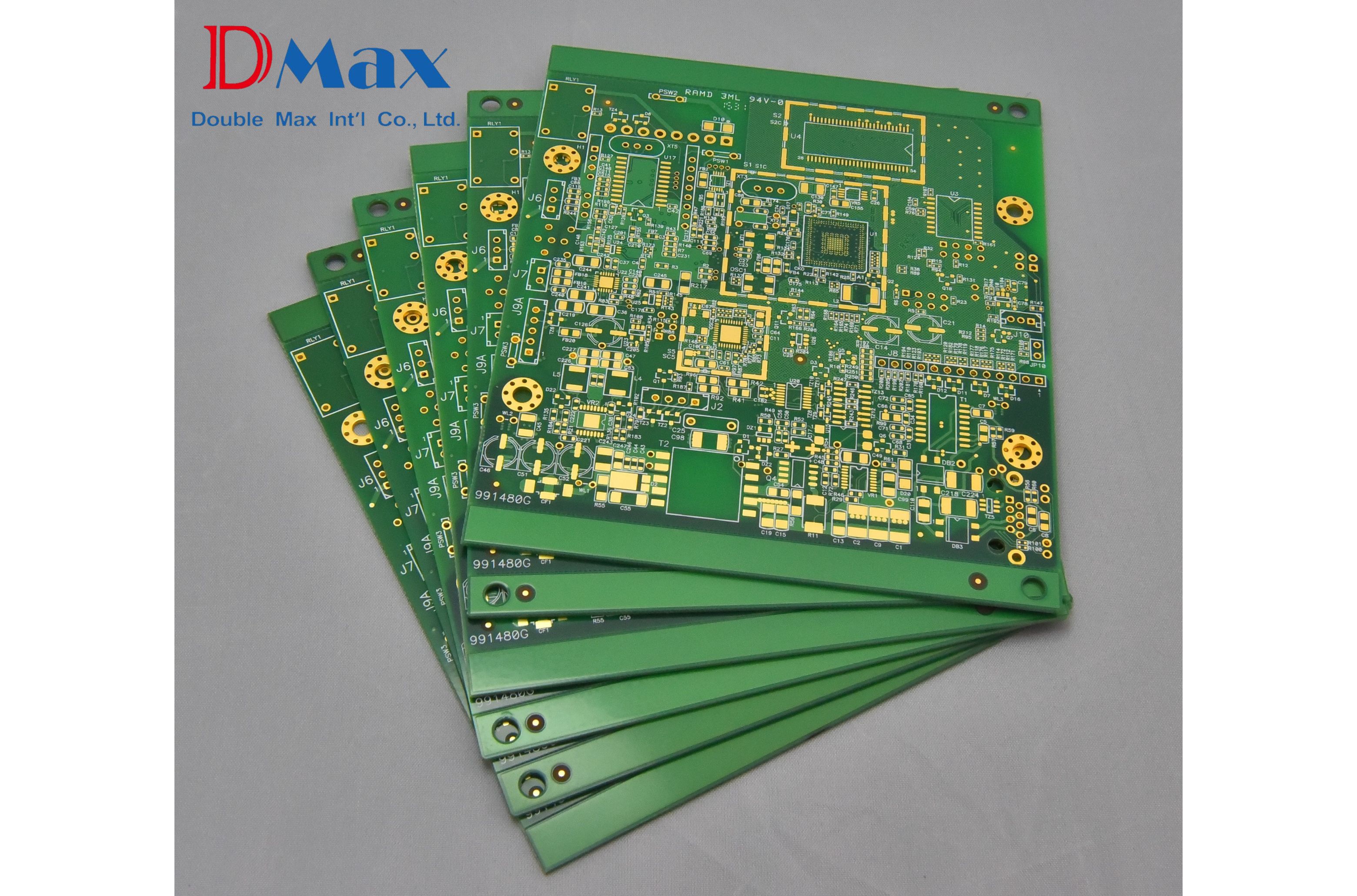

A competitive PCBA manufacturer can support both small-batch prototyping and full-scale production, providing flexibility at various stages of product development. Advanced capabilities may include BGA, QFN, and 0201 component mounting, conformal coating, firmware programming, and functional testing to ensure product performance and compliance with technical standards.

🔹 Advantages of Turnkey PCBA Services and One-Stop Suppliers

Many companies prefer to work with PCBA manufacturers that offer turnkey PCBA services—handling not just the assembly but also component sourcing, quality control, functional testing, packaging, and logistics.

A reliable one-stop PCBA manufacturer streamlines supply chain operations, minimizes errors, reduces lead times, and accelerates time-to-market, especially beneficial for OEMs and startups alike.

🔹 Standard Collaboration Process with a PCBA Manufacturer

Working with a professional PCBA manufacturer typically involves the following steps:

1. Requirement clarification and submission of technical documents (e.g., Gerber files, BOM, pick-and-place, testing specs)

2. Quotation and lead time confirmation

3. Prototype production and customer validation (if needed)

4. Mass production and quality inspection (AOI, X-ray, functional testing)

5. Final packaging and shipping

6. Post-production support and technical feedback (if applicable)

🔹 How to Choose the Right PCBA Manufacturer

When selecting a qualified PCBA manufacturer, consider the following factors:

• Possession of certifications such as ISO 9001, RoHS, and IPC-A-610

• Capability to support both prototypes and high-volume production

• Ability to handle component sourcing and testing

• Experience with complex components like BGA and QFN

• Transparent quality control processes and traceability

• Familiarity with your specific industry (e.g., medical, automotive, telecom)

These criteria help ensure a trustworthy long-term PCBA manufacturing partner.

🔹 Does a PCBA Manufacturer Accept Mini Orders?

Most modern PCBA manufacturers support small-volume or prototype production (as few as 5 to 50 pieces) to accommodate product development needs. However, it's important to note that the cost per unit may be higher for small batches, and some components may have MOQ (Minimum Order Quantity) restrictions. Partnering with a flexible PCBA supplier helps reduce entry costs for startups and R&D teams.

🔹 PCBA Lead Time and Key Influencing Factors

Lead time for PCBA varies depending on project size and complexity. A general estimate is:

• Prototyping: 5–10 working days

• Small-batch production: 10–15 working days

• High-volume production: 15–30+ working days

Factors influencing delivery time include turnkey service scope, component availability, specified brands, test requirements, and PCB layer count. An experienced PCBA manufacturer helps mitigate these risks and improve overall timeline reliability.

🔹 PCBA Packaging and Shipping Methods

A reliable PCBA manufacturer uses appropriate packaging based on product characteristics and shipping methods, including:

• ESD (Electrostatic Discharge) protective bags

• Bubble wrap, foam layers, or anti-static trays

• Labeled moisture-proof outer cartons with tracking codes

For industries like medical or automotive, cleanroom packaging or special handling may also be provided. Most PCBA suppliers support global shipping via air, sea, or express courier depending on order volume and urgency.

🔹 DMAX – Your Trusted PCBA Manufacturer in Taiwan

DMAX is a professional PCBA manufacturer based in Taiwan, offering turnkey solutions that include PCB fabrication, component sourcing, SMT/THT assembly, functional testing, and full-process quality assurance. DMAX serves global OEMs and startups across industries such as industrial automation, medical technology, automotive systems, and networking devices.

With ISO 9001 certification, IPC-compliant workflows, fast delivery capability, and a flexible one-stop manufacturing model, DMAX helps clients shorten product development cycles and enhance production efficiency—making it a reliable long-term partner for high-performance PCBA solutions.

PCBA manufacturer

RECOMMENDATIONS

_2_cover.png)

_cover.png)