FAQ

What are turnkey PCBA services and why are they important?

What are turnkey PCBA services and why are they important?

🔹 Understanding Turnkey PCBA: A One-Stop Manufacturing Model

Turnkey PCBA services refer to a full-service electronics manufacturing model in which a PCBA manufacturer manages the entire production process—from PCB fabrication and component sourcing to assembly, testing, and final delivery. Customers only need to provide the design files and specifications, while the manufacturer handles everything else. This model ensures streamlined coordination and production under a single point of control.

🔹 Why Turnkey PCBA Is Crucial in Modern B2B Manufacturing

With increasing time-to-market pressures and global sourcing challenges, turnkey PCBA solutions help businesses save time, reduce risks, and optimize project costs. By consolidating all stages of the process under one turnkey PCBA manufacturer, companies can avoid delays, miscommunication, and quality inconsistencies that often arise from managing multiple vendors.

Turnkey PCBA is especially valuable for OEMs, startups, and engineering teams that require fast, reliable, and cost-effective manufacturing with minimal internal overhead.

🔹 What’s Included in a Typical Turnkey PCBA Workflow?

A standard turnkey PCBA project typically includes:

Engineering file review and documentation analysis (e.g., BOM, Gerber, DFM)

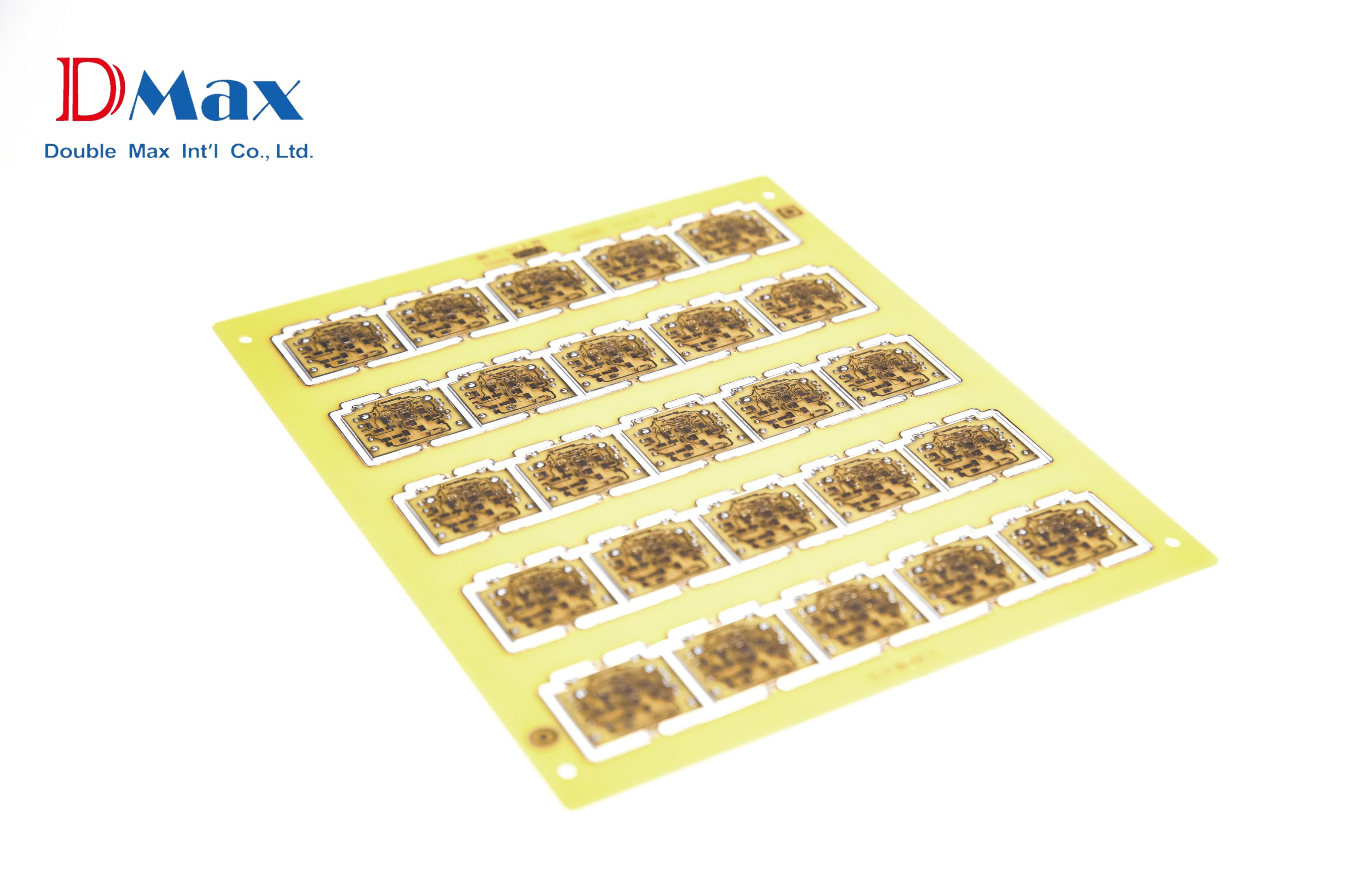

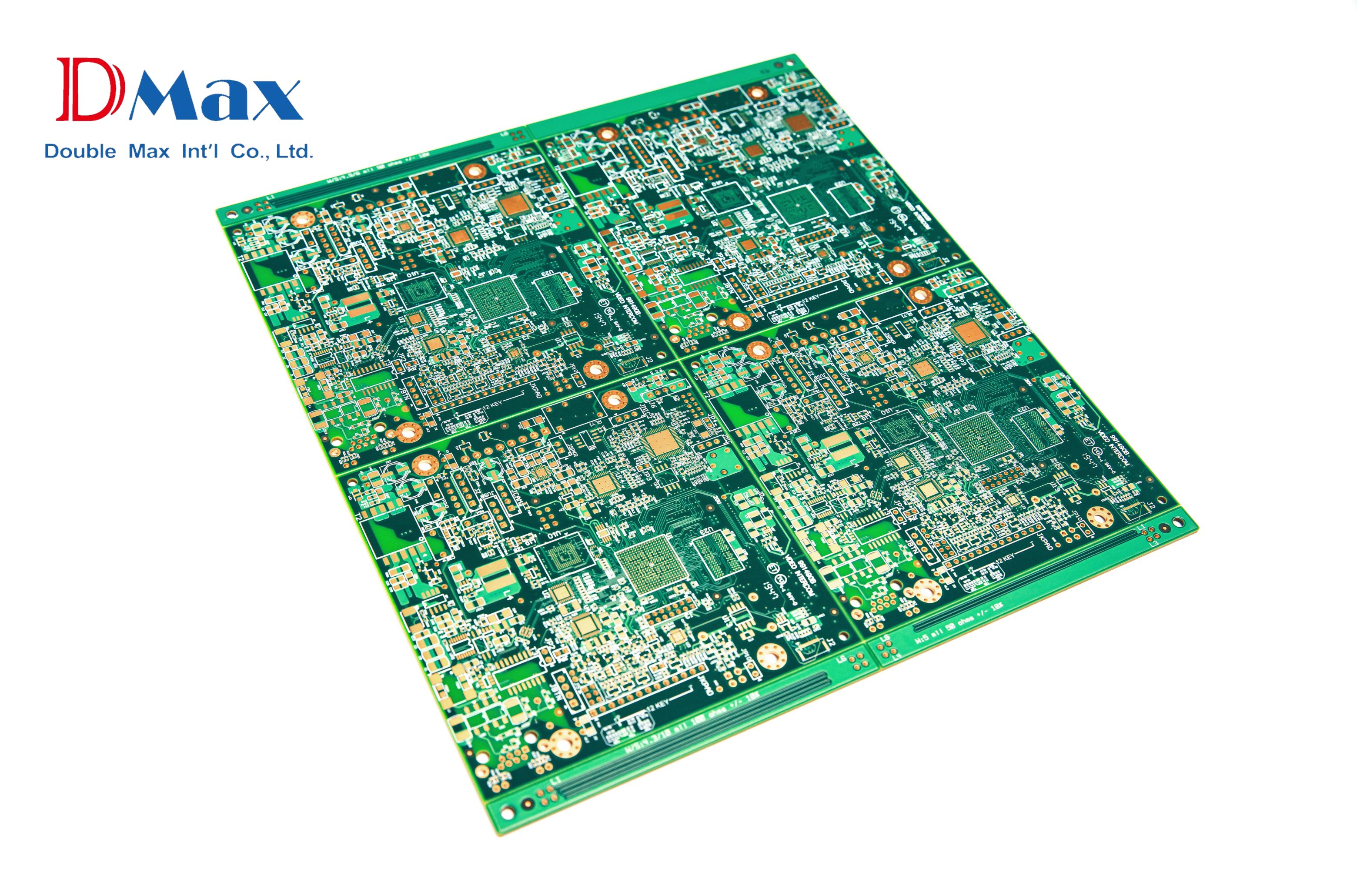

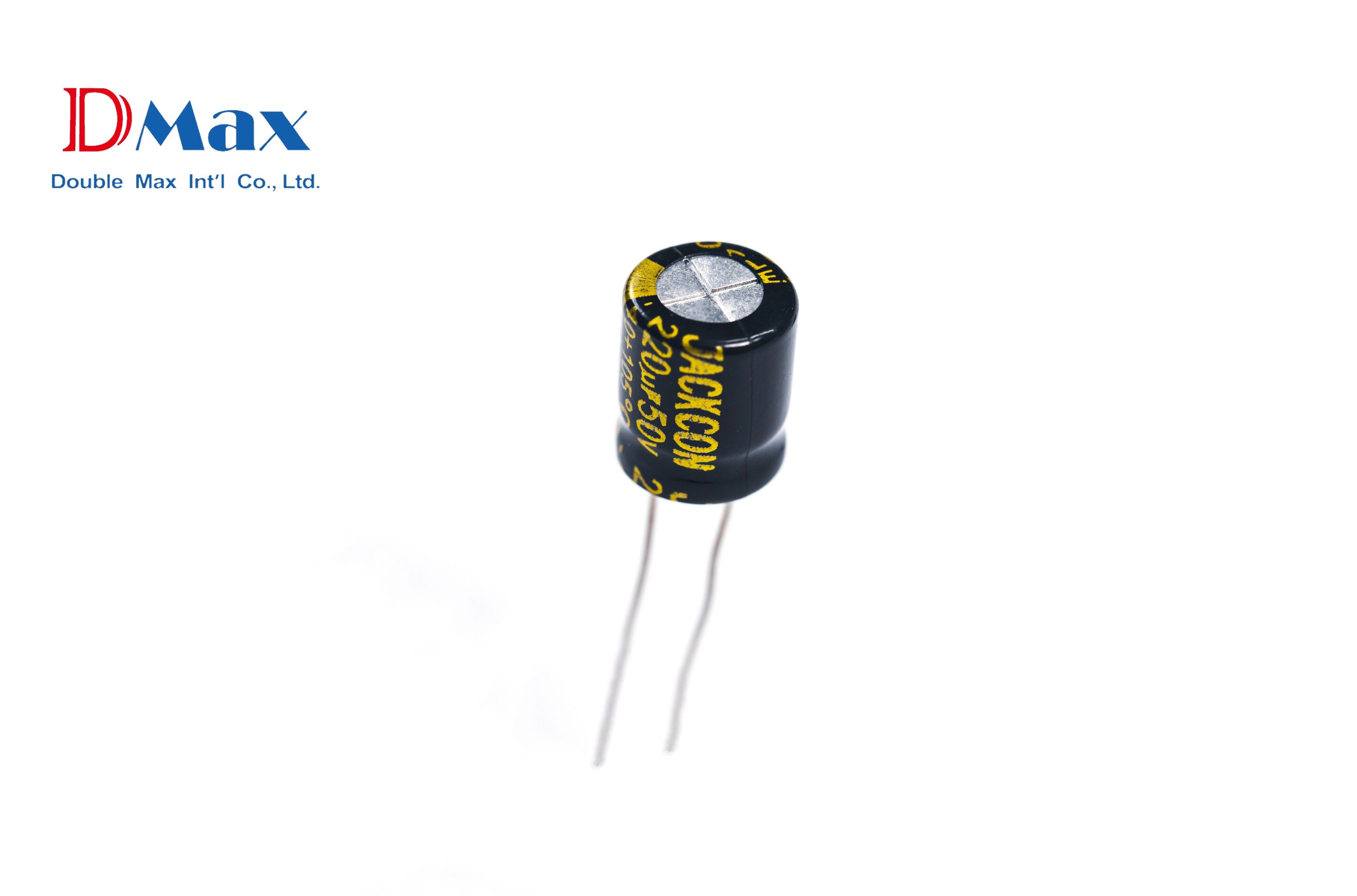

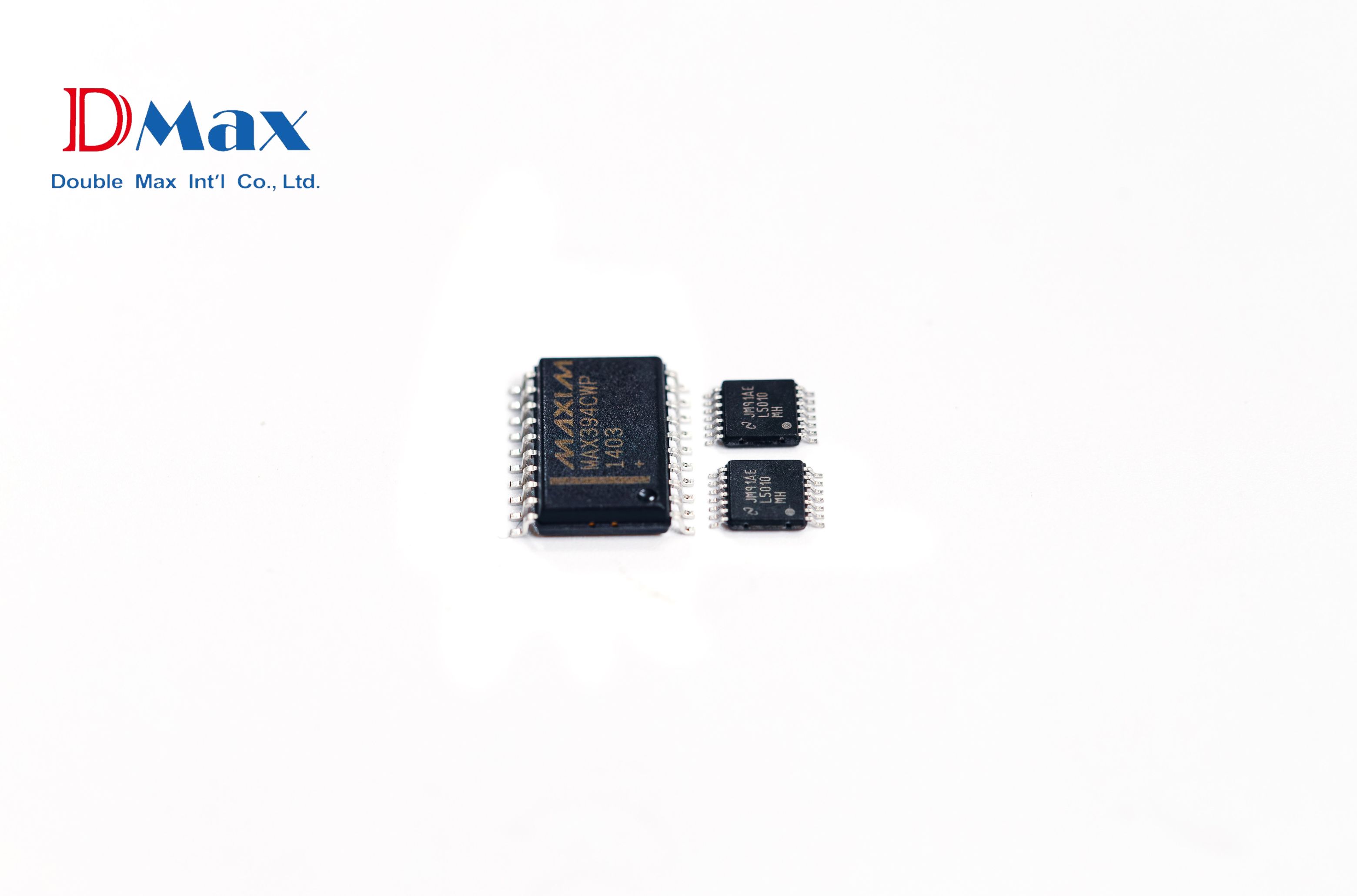

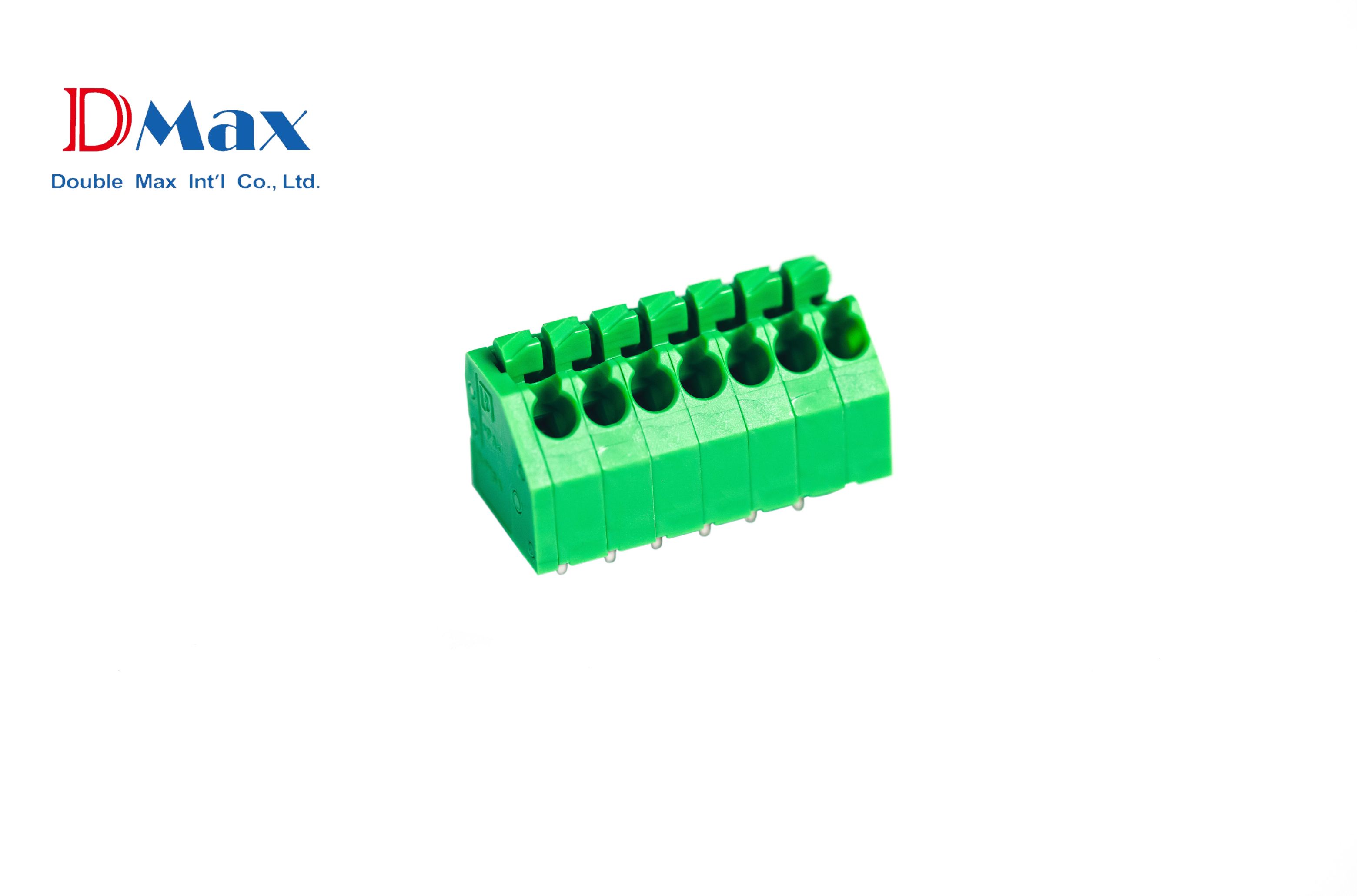

PCB fabrication and global component procurement

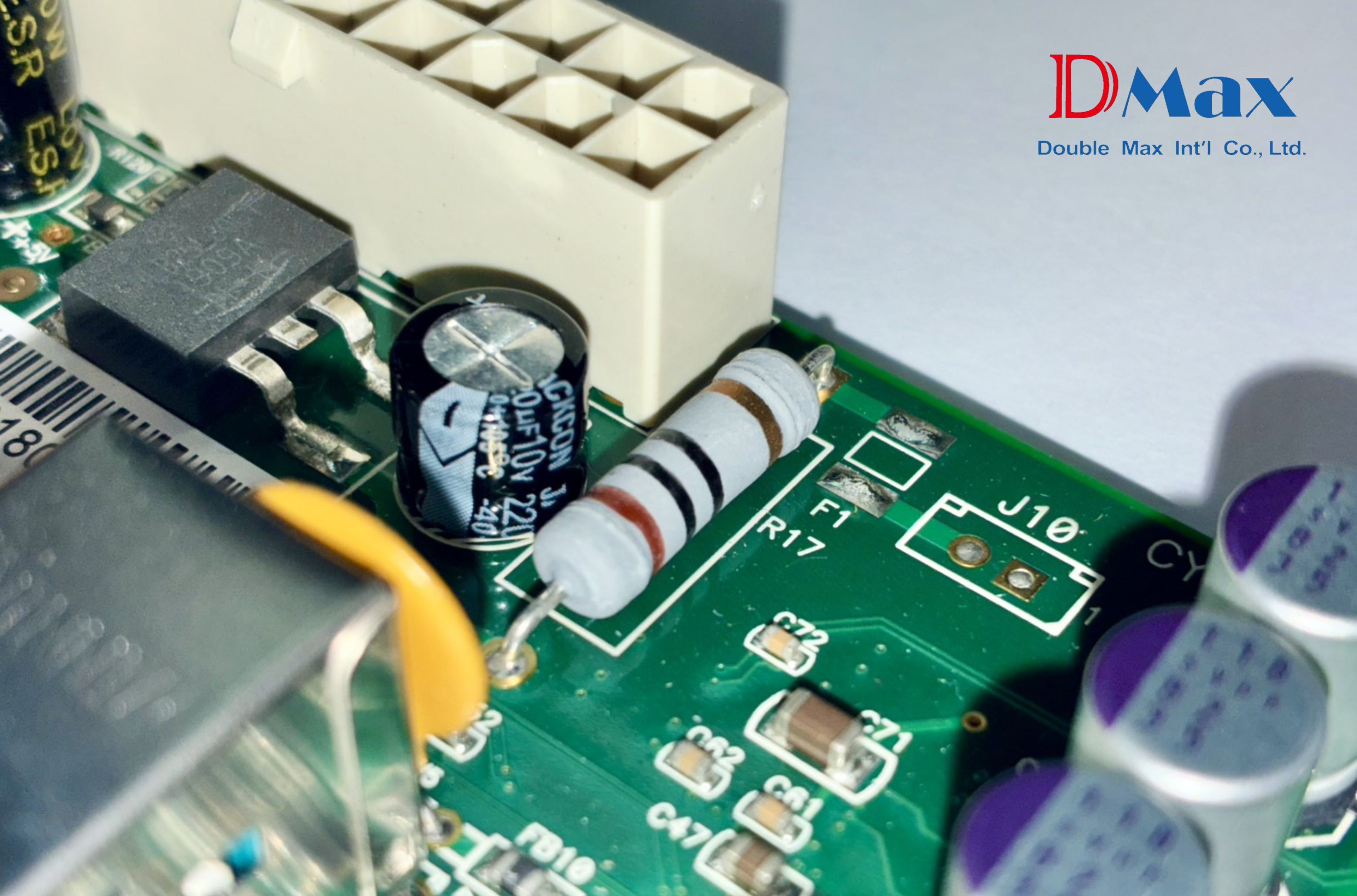

SMT and THT assembly processes

Testing procedures (AOI, ICT, functional testing)

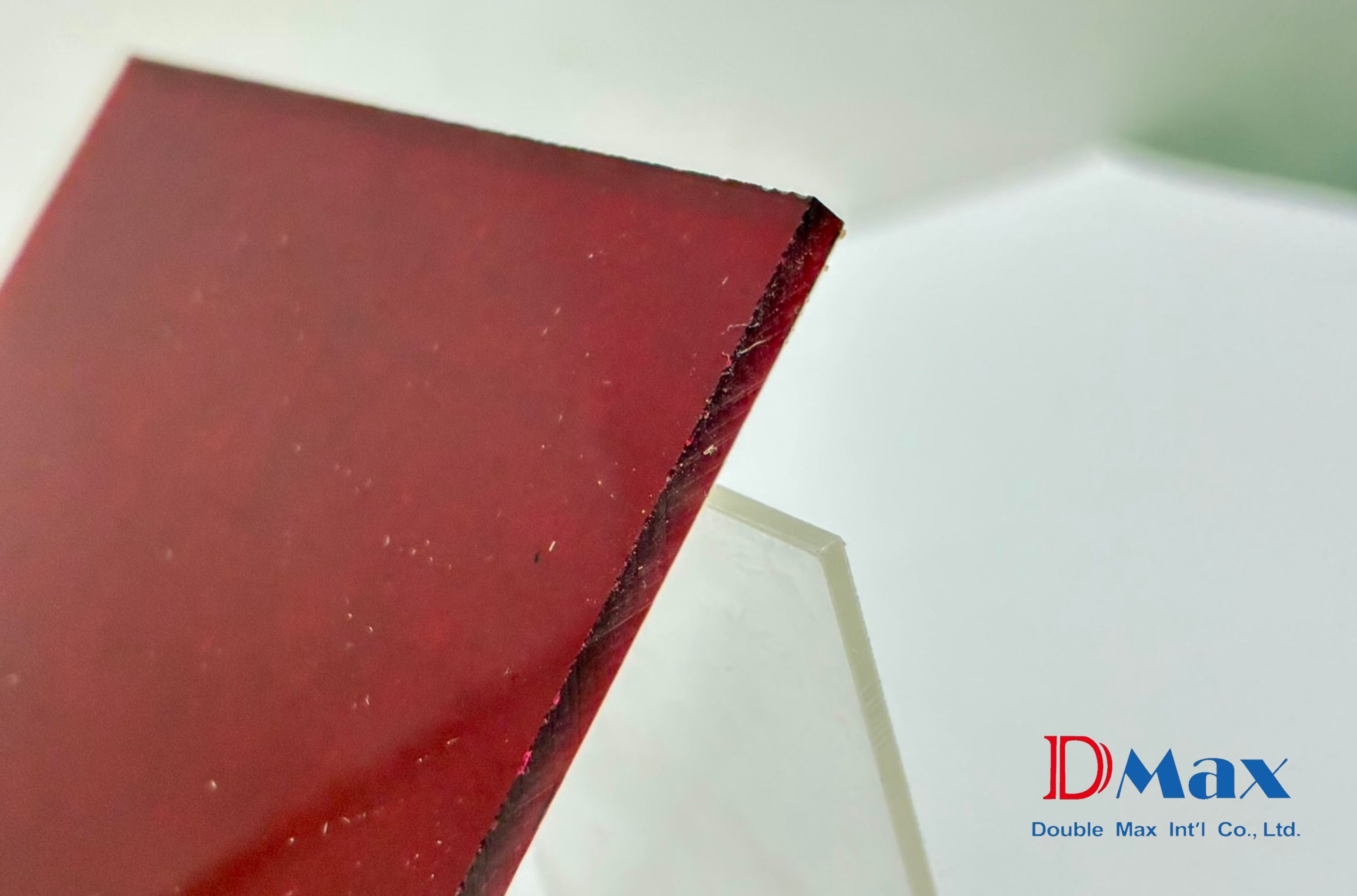

Secondary processing (e.g., conformal coating, potting)

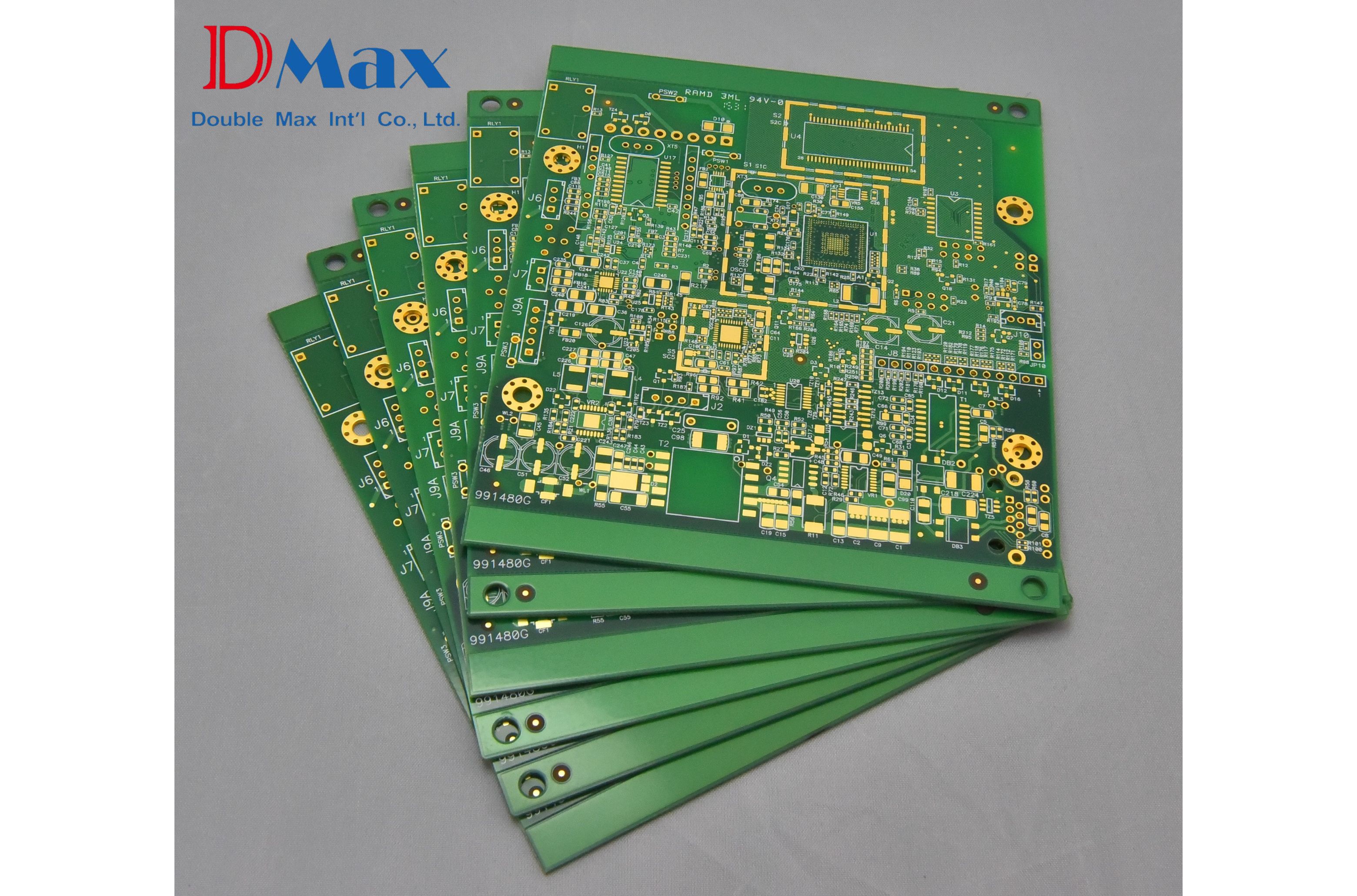

Final inspection, packaging, and shipment

Having a single turnkey PCBA partner manage all phases ensures process consistency, traceability, and better project control.

🔹 Advantages of Choosing Turnkey PCBA Over Fragmented Sourcing

Partnering with a turnkey PCBA manufacturer offers several key advantages over dealing with multiple vendors:

✅ Unified Quality Control: One team handles everything, ensuring process alignment and minimized error rates

✅ Faster Lead Times: Reduced coordination and synchronized timelines improve delivery speed

✅ Cost Optimization: Centralized procurement and bulk processing reduce overall costs

✅ Integrated Engineering Support: Easier to solve design-for-manufacturing issues in-house

✅ Full Documentation: Test reports, quality records, and traceability logs are well organized

These advantages make turnkey PCBA a strategic choice for high-reliability product development.

🔹 Who Should Consider Turnkey PCBA Services?

Turnkey PCBA is particularly beneficial for:

�� Overseas OEMs and global buyers lacking in-house supply chain support

🚀 Startups and product developers with limited resources

🧠 Companies developing complex electronics that require tight integration

⏱️ Projects under strict deadlines that need fast prototyping and transition to volume production

Choosing the right turnkey PCBA service provider can significantly accelerate product launch cycles.

🔹 Beyond Turnkey PCBA: Other Service Models Available

While turnkey PCBA is comprehensive, many manufacturers offer alternative PCBA service models depending on customer needs:

✅ Consigned PCBA Services

The customer provides all or some of the components, and the manufacturer handles assembly and testing.

✅ Partial Turnkey Services

A hybrid approach where critical or high-value components are supplied by the customer, while the rest are sourced and assembled by the manufacturer.

✅ Engineering & DFM Support

Experienced PCBA manufacturers may offer BOM optimization, Gerber reviews, and manufacturability consulting to reduce errors and costs.

✅ Testing-Only Services

Some clients may request stand-alone functional, AOI, or environmental testing on completed assemblies.

These flexible models allow clients to tailor PCBA services based on budget, supply chain structure, and project maturity.

🔹 How to Select a Reliable Turnkey PCBA Manufacturer

When evaluating a turnkey PCBA supplier, consider the following criteria:

Do they offer both PCB fabrication and SMT/THT assembly in-house?

Can they manage global component sourcing and procurement?

Do they support advanced component mounting (e.g., BGA, QFN)?

Are they capable of full-process documentation, testing, and traceability?

Do they meet quality standards like ISO 9001, RoHS, and IPC?

These factors are essential to ensure you partner with a trustworthy turnkey PCBA manufacturer.

🔹 DMAX – A Proven Turnkey PCBA Partner

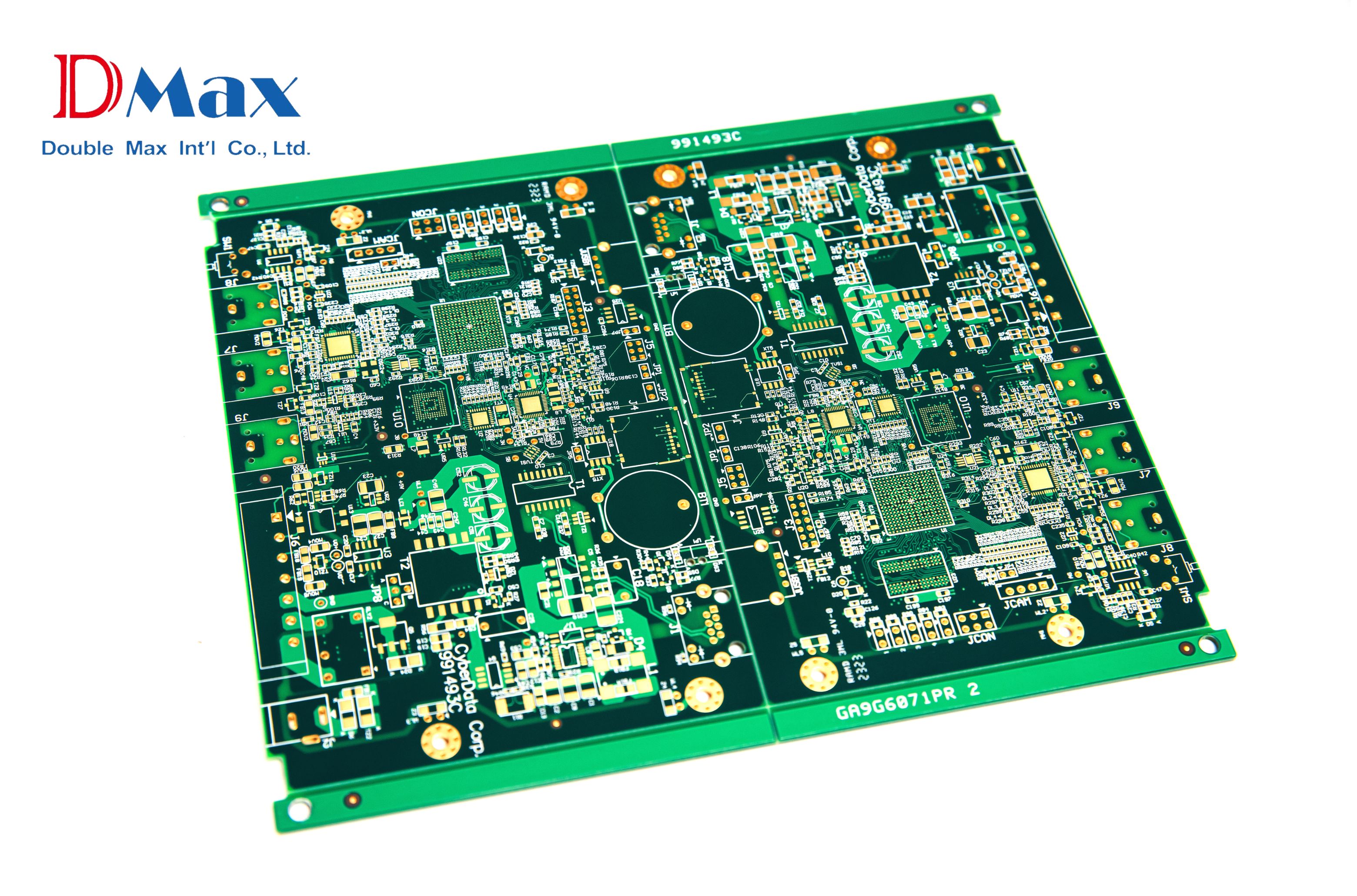

DMAX is a Taiwan-based PCBA manufacturer offering fully integrated turnkey PCBA services for industries such as industrial automation, medical devices, telecom systems, and automotive electronics.

Our capabilities include PCB production, component sourcing, SMT/THT assembly, ICT/AOI/functional testing, and value-added services like packaging and logistics. With ISO 9001-certified processes, flexible manufacturing models, and global delivery support, DMAX helps customers accelerate development, reduce risk, and deliver superior electronic products to market.

- What does a PCBA manufacturer typically provide?

- Can a PCBA manufacturer support both prototyping and mass production?

RECOMMENDATIONS

_2_cover.png)

_cover.png)