FAQ

Can a PCBA manufacturer support both prototyping and mass production?

Can a PCBA manufacturer support both prototyping and mass production?

🔹 Flexible Capabilities of a Modern PCBA Manufacturer

A professional PCBA manufacturer should be capable of supporting both low-volume prototyping and high-volume mass production, meeting the needs of products at various stages of development. From new product introduction (NPI) to large-scale manufacturing, businesses across industries require adaptable and scalable PCBA services.

🔹 The Role and Features of PCBA Prototyping

Prototyping is a critical phase during early product development. It verifies the feasibility of design, layout accuracy, and functional stability. An experienced PCBA manufacturer should be able to deliver high-quality prototypes quickly, with the following features:

Fast turnaround (typically 3–10 working days)

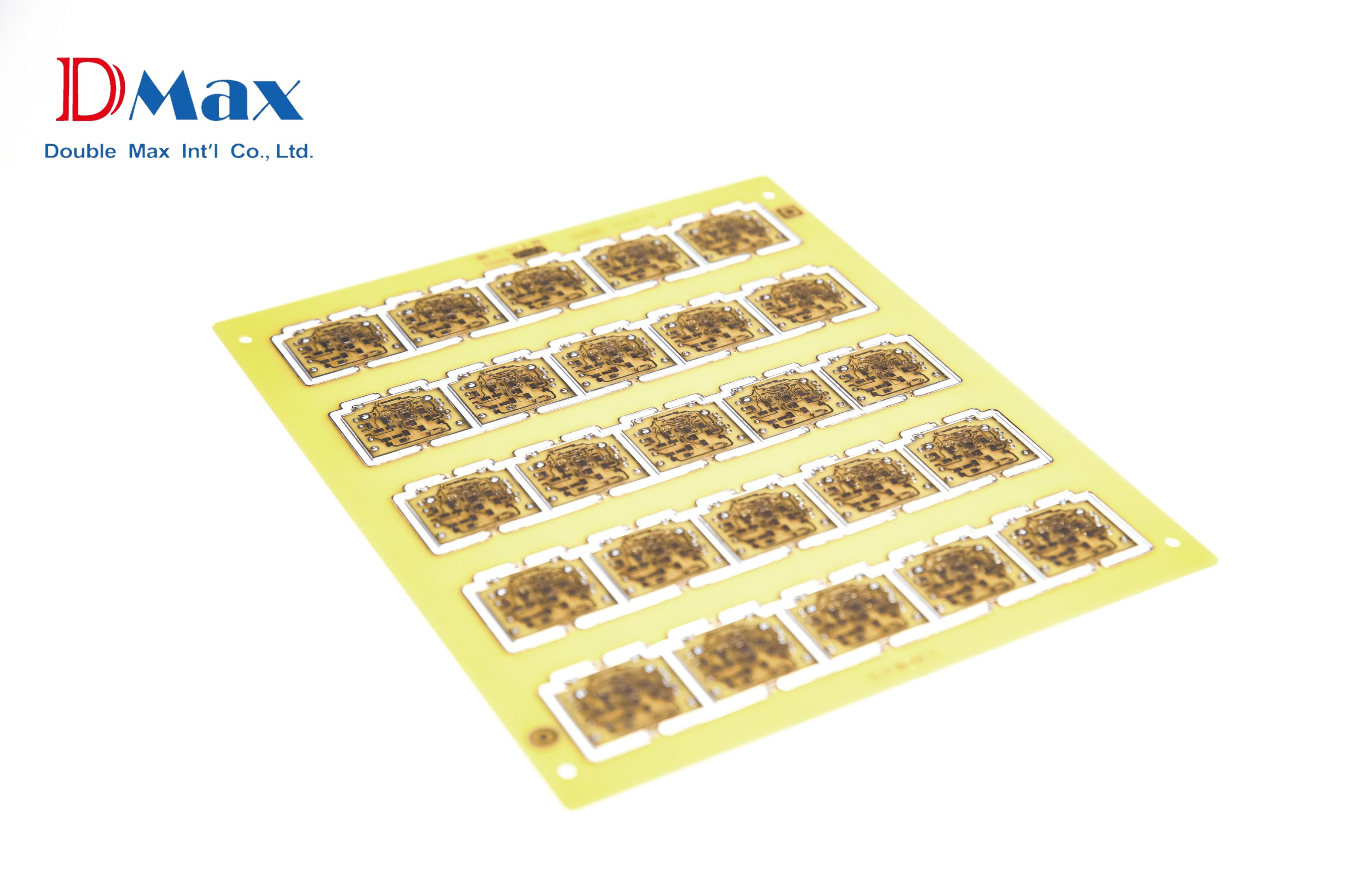

Support for low-quantity PCBA prototype builds

DFM (Design for Manufacturability) and BOM validation

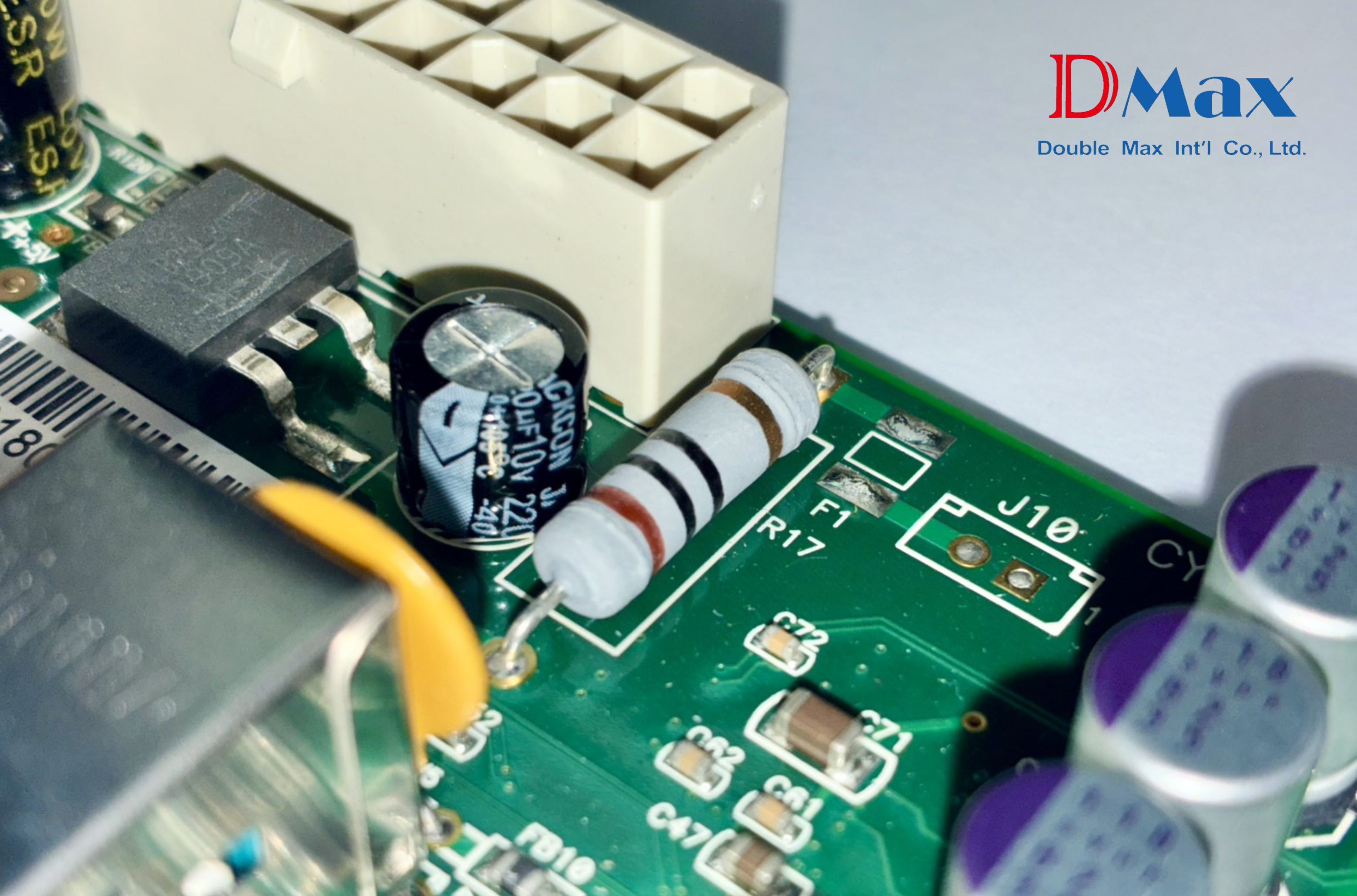

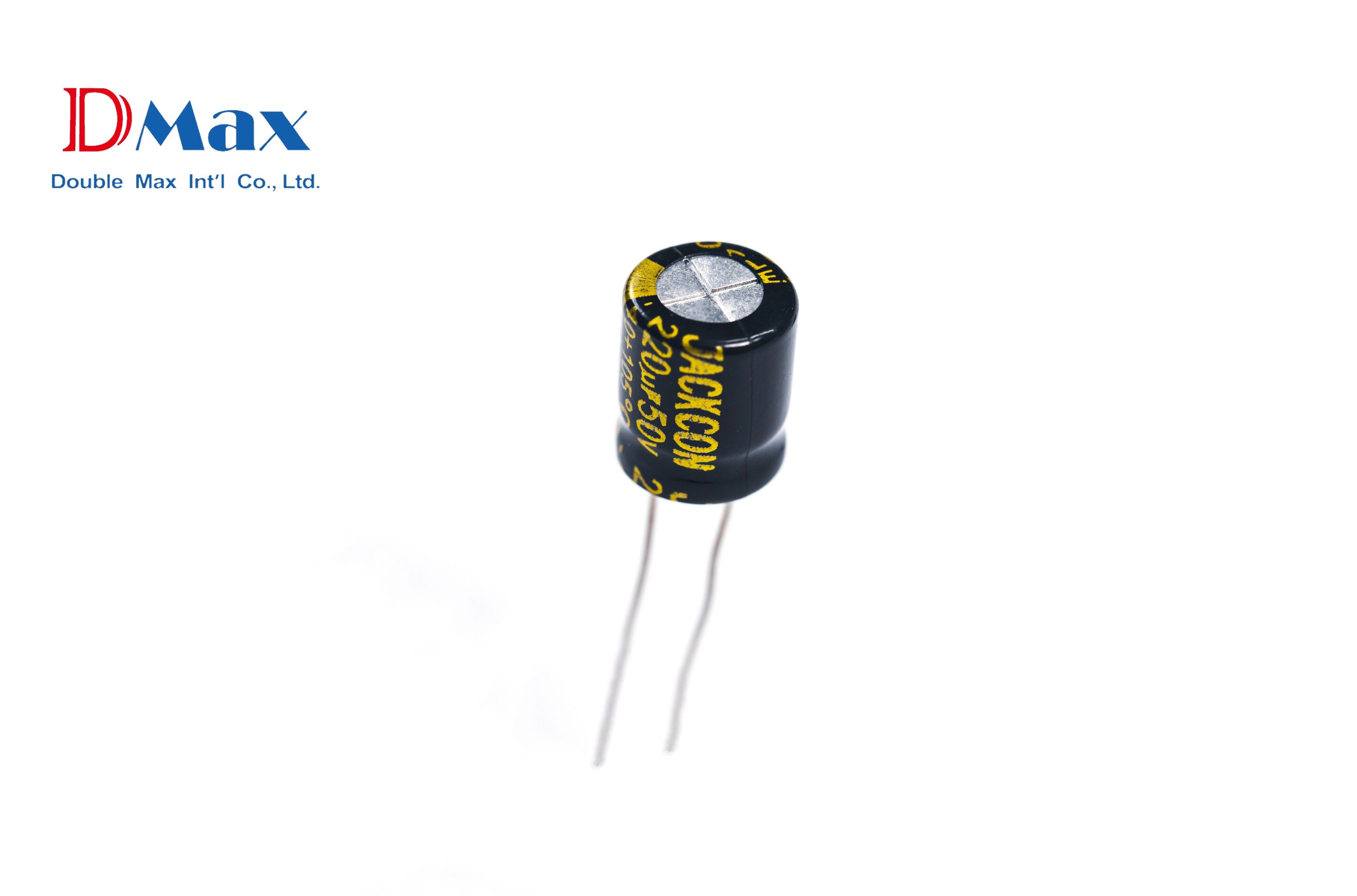

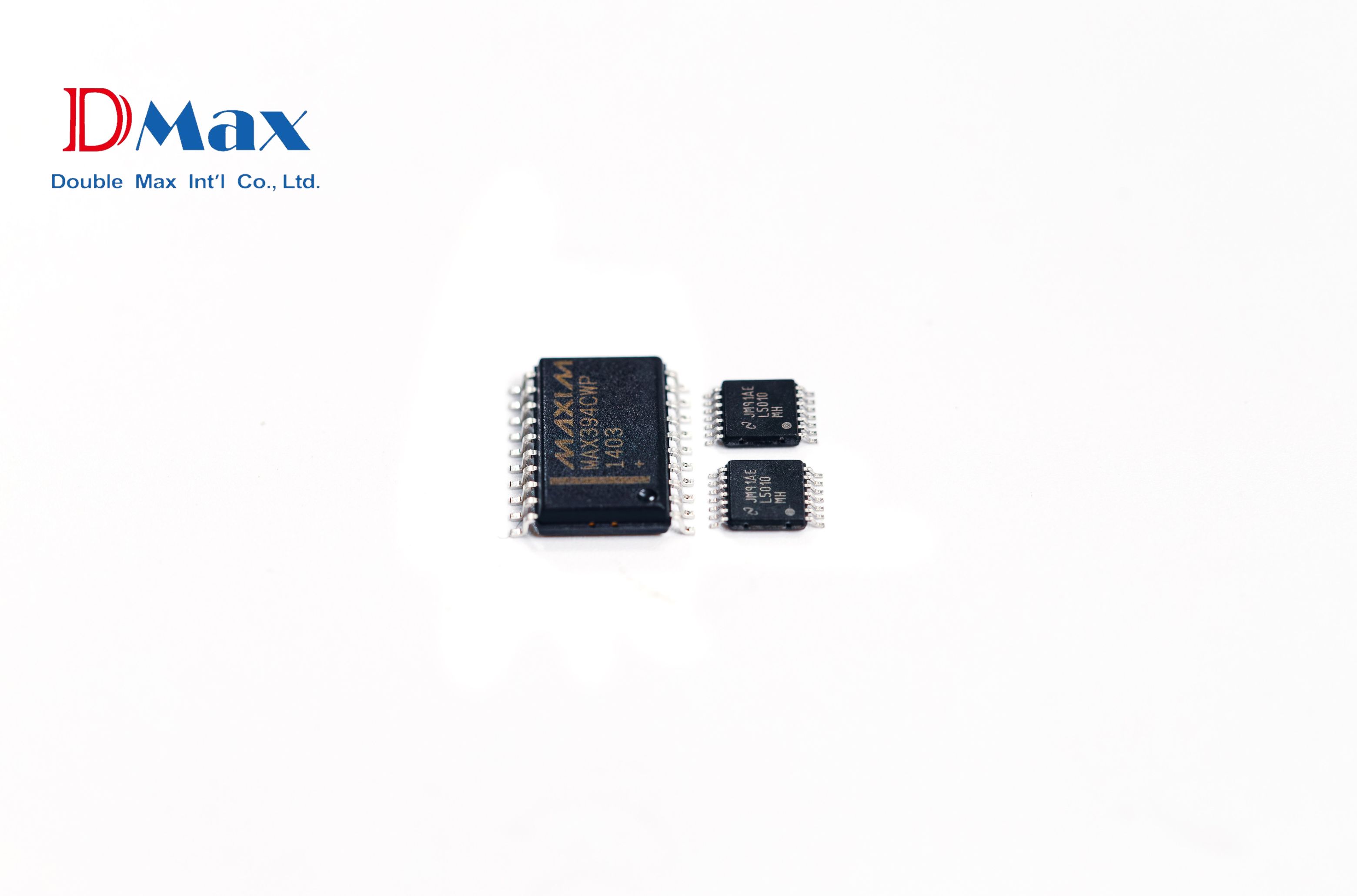

Capability to assemble complex components (e.g., BGA, QFN, 0201)

🔹 Key Considerations for PCBA Mass Production

Once the design has been validated through prototypes, the product enters the mass production stage. This phase requires:

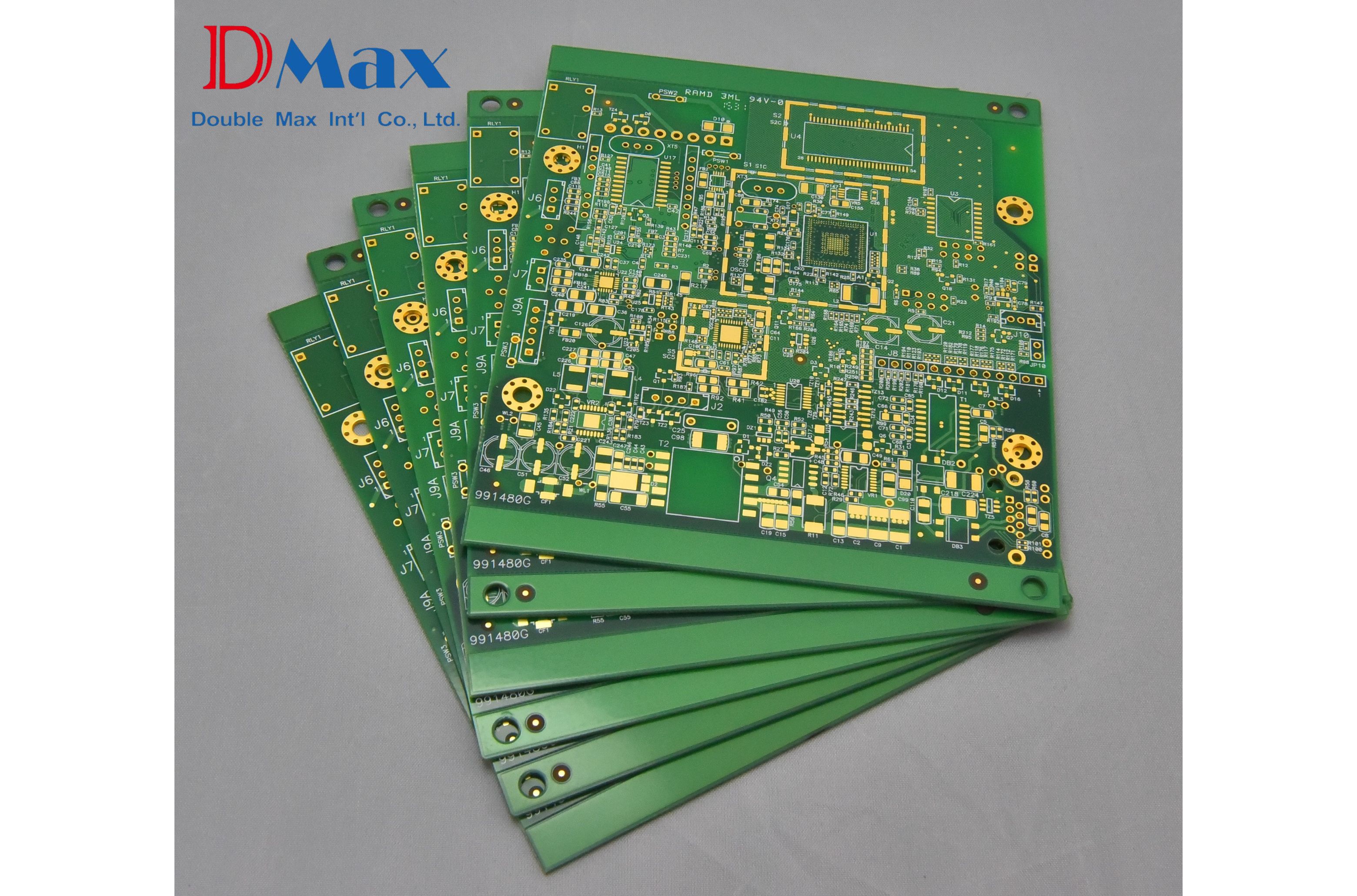

Stable yield rates and consistent processes

Component sourcing strategies and supply chain management

In-line and final inspection procedures

Customized packaging, labeling, and traceability

Compliance with standards such as IPC and ISO 9001

A qualified PCBA manufacturer will establish dedicated production parameters and quality control protocols to ensure consistent results.

🔹 Seamless Transition from Prototyping to Production

A well-organized PCBA manufacturer offers integrated workflows that transition smoothly from prototyping to small-batch trial runs and full-scale mass production. This is especially valuable for businesses that aim to reduce development time and bring products to market faster.

Manufacturers with strong NPI (New Product Introduction) experience can bridge the gap between R&D and volume production efficiently—particularly for complex and customized electronic assemblies.

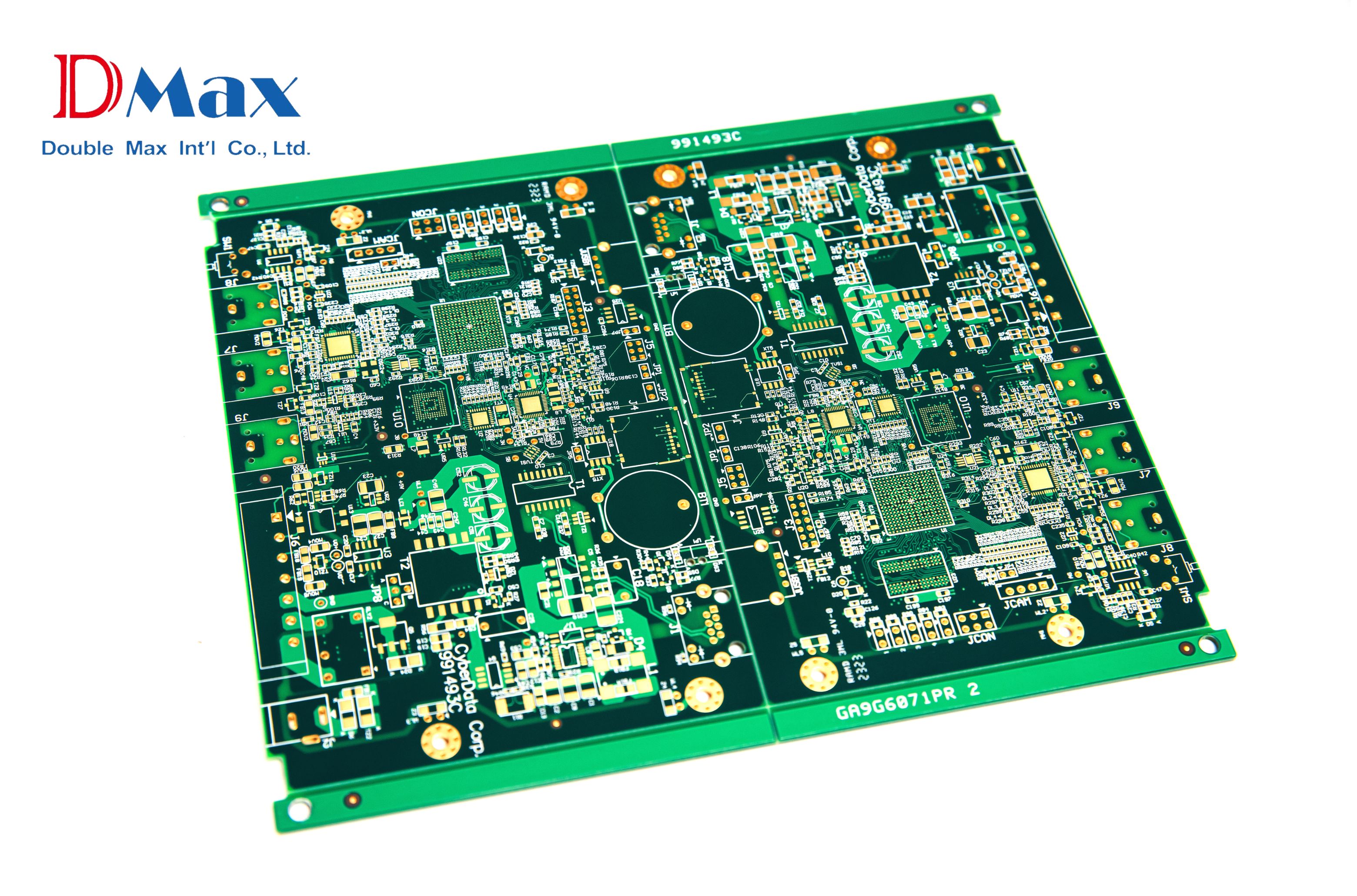

🔹 DMAX: Your One-Stop PCBA Partner from Prototype to Production

As a professional PCBA manufacturer in Taiwan, DMAX provides fully integrated support from prototyping to mass production. We accommodate low-quantity PCBA builds during early development stages and can scale to tens of thousands of units for volume production. DMAX offers:

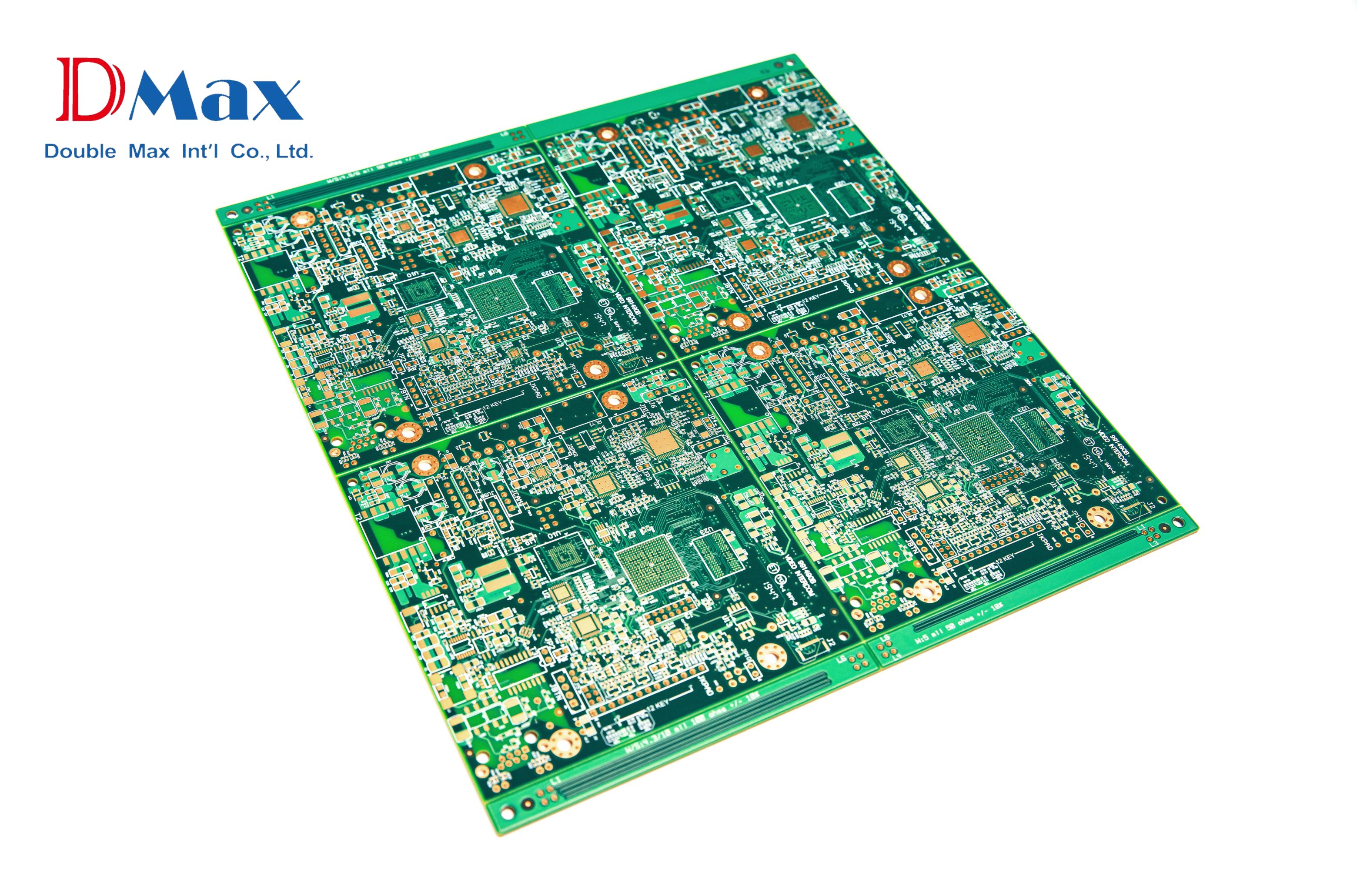

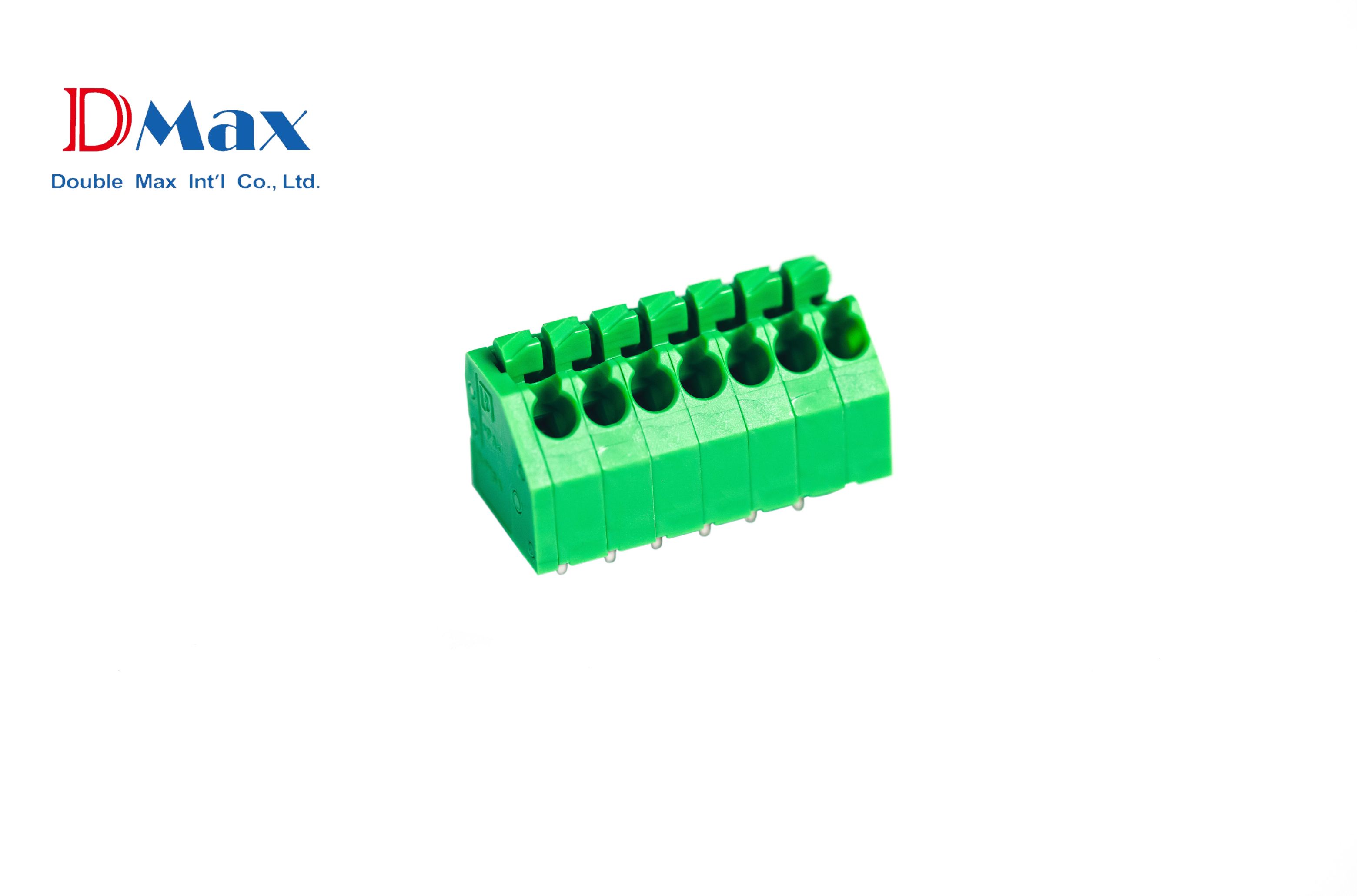

High-speed SMT and DIP assembly lines

Precision placement for 0201, BGA, QFN, and other fine-pitch components

Firmware programming and functional testing

Fast turnaround for small batches (as quick as 3 working days)

ISO 9001-certified processes and multi-level quality control systems

Whether for startups or established OEMs, DMAX is a reliable PCBA partner that supports every phase of your product lifecycle—from design validation to stable mass production.

- What are turnkey PCBA services and why are they important?

- Which industries rely most heavily on PCBA manufacturing services?

RECOMMENDATIONS

_2_cover.png)

_cover.png)