FAQ

Which industries rely most heavily on PCBA manufacturing services?

Which industries rely most heavily on PCBA manufacturing services?

🔹 PCBA Manufacturing: Essential to Modern Electronics

PCBA (Printed Circuit Board Assembly) manufacturing services are a critical component in the production of nearly all modern electronic devices. From consumer gadgets to industrial systems, PCBA enables functionality, connectivity, and intelligence. High-quality, reliable PCBA solutions are especially vital for industries with complex electronic design and mass production requirements. These include:

Consumer Electronics

Industrial Automation

Automotive Electronics

Medical Device Manufacturing

Telecommunications & Networking

Aerospace and Defense

IoT Devices & Smart Systems

These sectors rely on professional PCBA manufacturers to deliver high-reliability solutions that meet both stringent technical requirements and aggressive development timelines.

🔹 Detailed Industry Applications of PCBA Manufacturing Services

Consumer Electronics

Devices such as smartphones, tablets, smart appliances, and wearables represent the largest demand for PCBA manufacturing. These products require highly compact, cost-efficient assemblies with high component density and short production cycles.

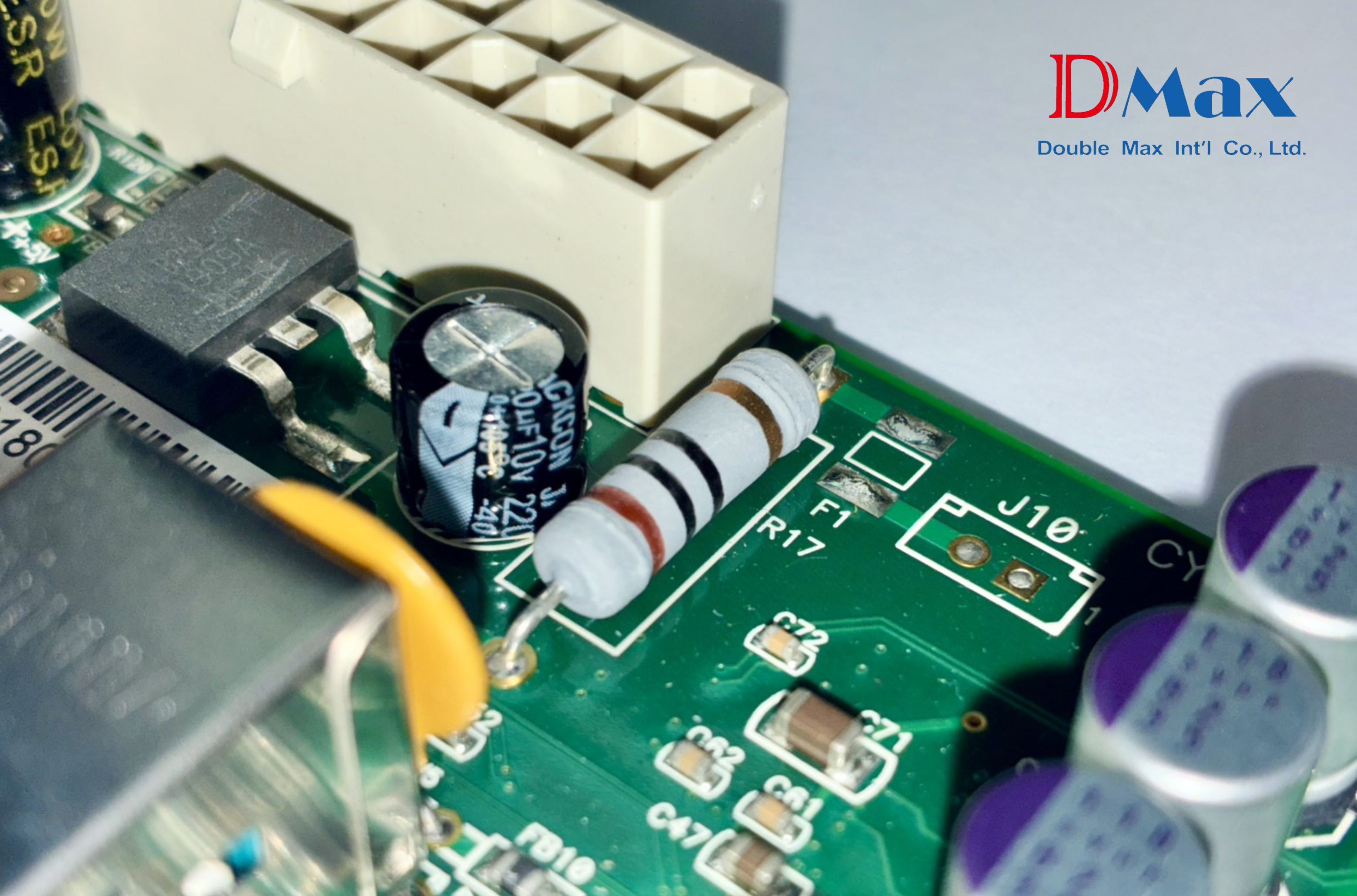

Industrial Automation Equipment

Automation systems including PLCs, HMIs, and industrial sensors require robust, long-life PCBAs designed to withstand vibration, temperature variation, and electrical interference. Long lifecycle support is critical.

Automotive Electronics

Modern vehicles, including EVs and autonomous platforms, integrate advanced electronics such as ECUs, battery management systems, and ADAS modules. These require automotive-grade PCBAs that meet AEC-Q100 standards and deliver high thermal stability and shock resistance.

Medical Device Manufacturing

Medical imaging systems, monitoring instruments, and wearable health devices require ISO 13485-certified PCBA services, emphasizing strict quality control, hygiene compliance, and long-term performance.

Telecom & Networking

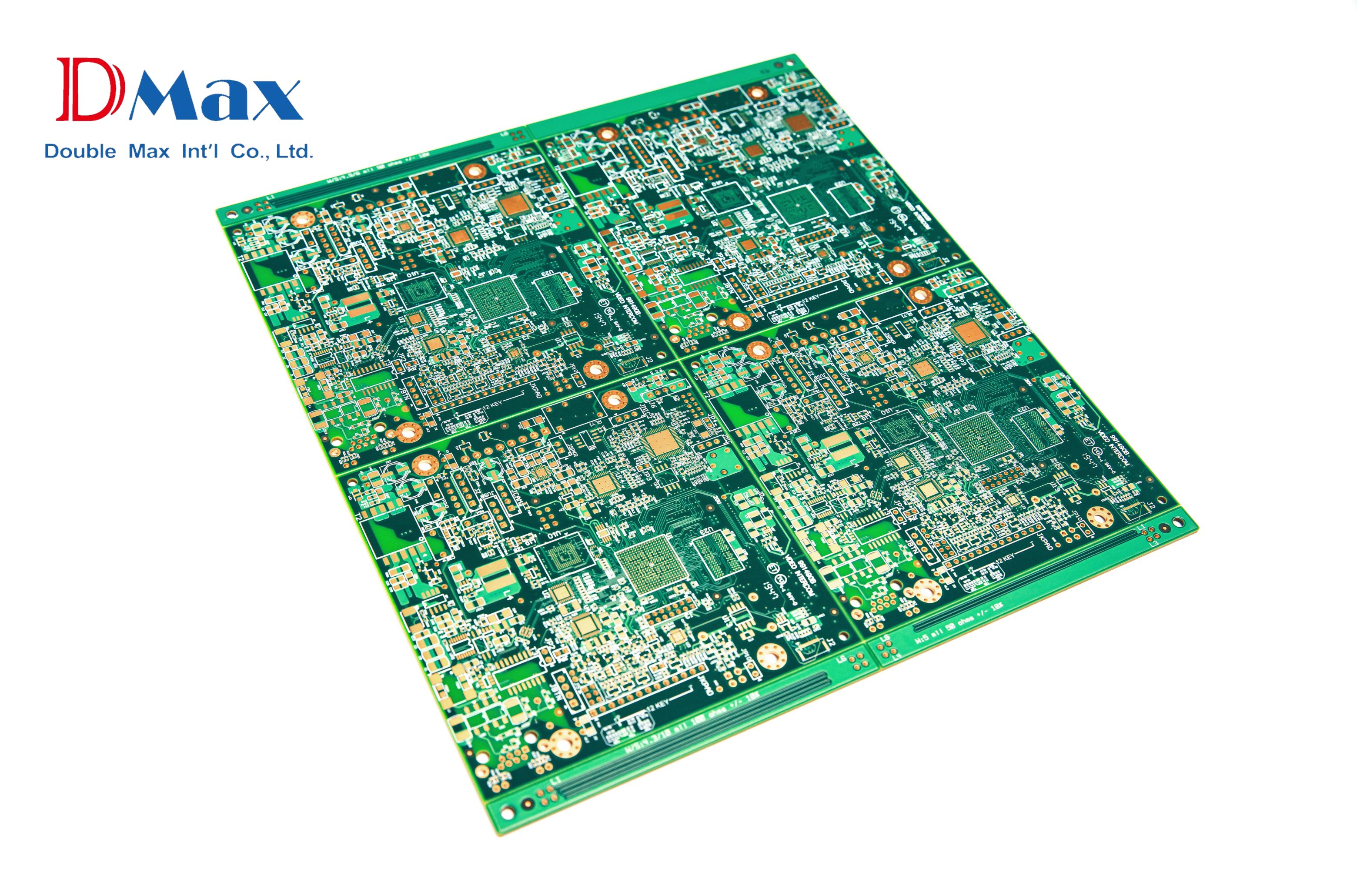

Routers, switches, base stations, and fiber modules typically require multilayer or HDI PCBs (12+ layers) to manage high-frequency signal transmission, low EMI, and continuous uptime—making PCB performance essential to product viability.

Aerospace and Defense

Applications such as avionics, radar systems, and tactical electronics demand mission-critical PCBA manufacturing, with exacting standards for reliability, documentation, and resilience in extreme environments.

IoT Devices and Embedded Systems

Smart meters, edge computing nodes, and wireless sensor networks use low-power, space-efficient PCBAs that require fast prototyping and seamless integration with RF modules and microcontrollers.

🔹 Technical Considerations by Industry

Each industry poses unique engineering demands on the PCBA manufacturer, requiring a deep understanding of:

Layer count & circuit density (e.g., HDI boards for networking or RF systems)

Material selection, such as high-frequency substrates or high-Tg laminates

Industry-specific certifications (e.g., ISO 13485, IATF 16949, MIL-STD)

Advanced testing protocols, including ICT, X-ray inspection, functional tests, and burn-in for high-reliability or life-critical applications

These factors drive the need for PCBA partners with comprehensive capabilities in engineering, quality assurance, and vertical integration.

🔹 How to Choose the Right PCBA Supplier for Your Industry

Choosing a qualified PCBA manufacturing partner is essential to reduce risk and accelerate time-to-market. When evaluating a supplier, consider the following:

Verified experience in your specific industry

Certified quality systems (e.g., ISO 9001, ISO 13485, IATF 16949)

Production scalability and flexible lead times

Full in-house inspection and test infrastructure

Engineering services such as DFM analysis and layout optimization

Partnering with a high-reliability PCBA manufacturer with deep industry knowledge ensures you receive tailored, compliant, and consistent production support—whether you're building consumer electronics or mission-critical systems.

🔹 DMAX: Industry-Proven PCBA Manufacturing Services

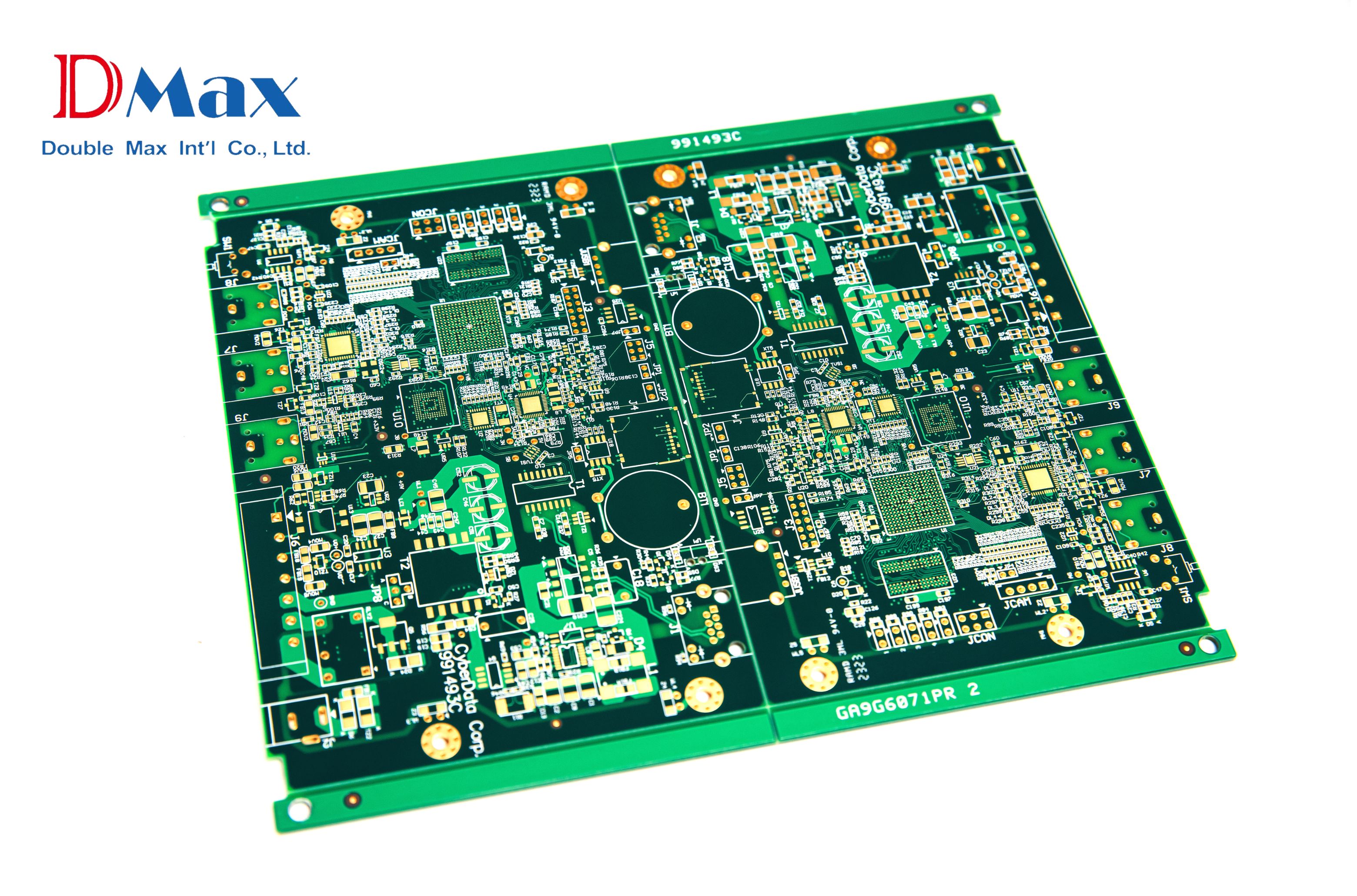

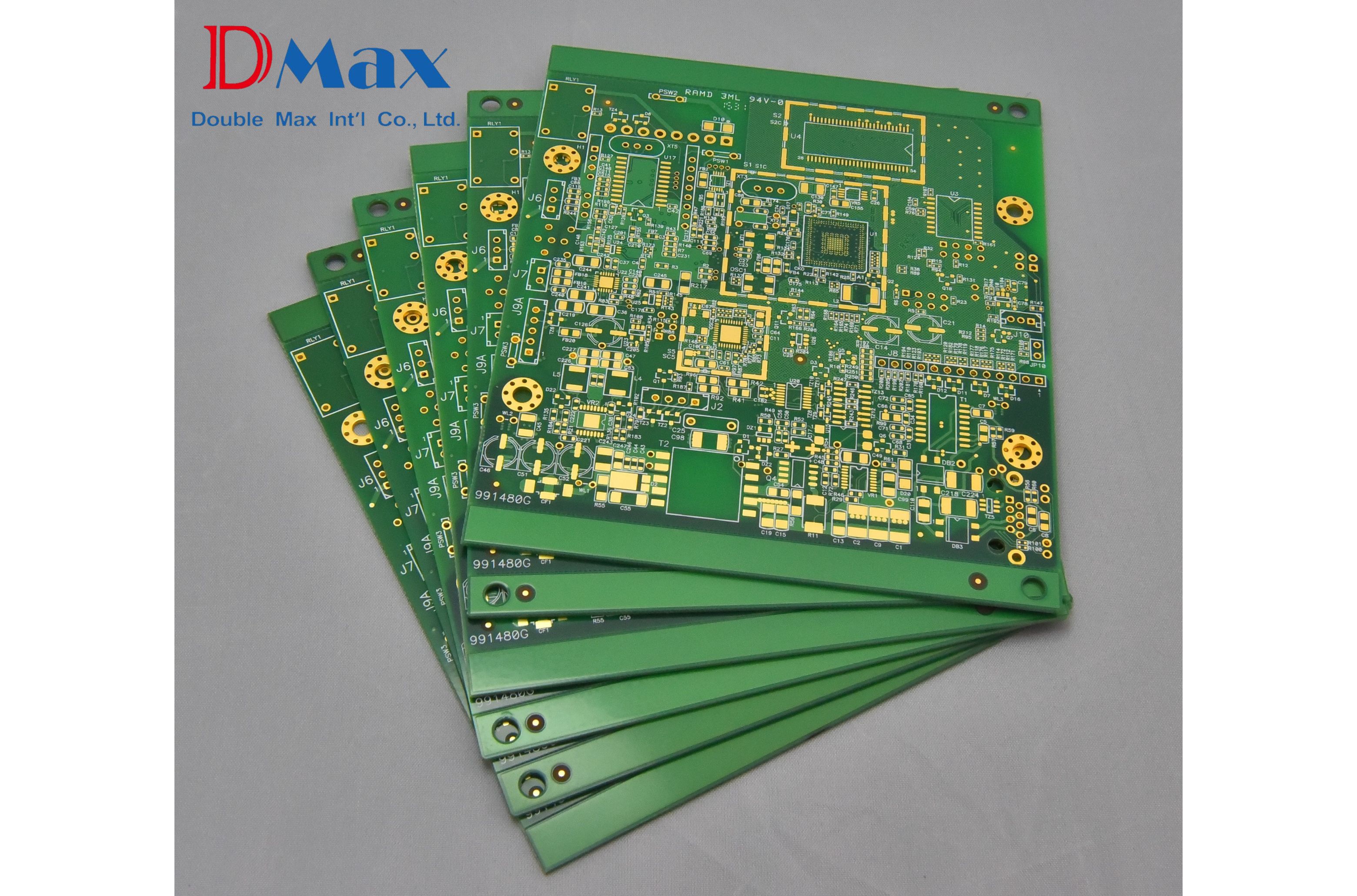

As a trusted PCBA manufacturer based in Taiwan, DMAX provides industry-specific PCBA manufacturing solutions for clients across the consumer electronics, medical, automotive, industrial, telecom, and defense sectors. We specialize in:

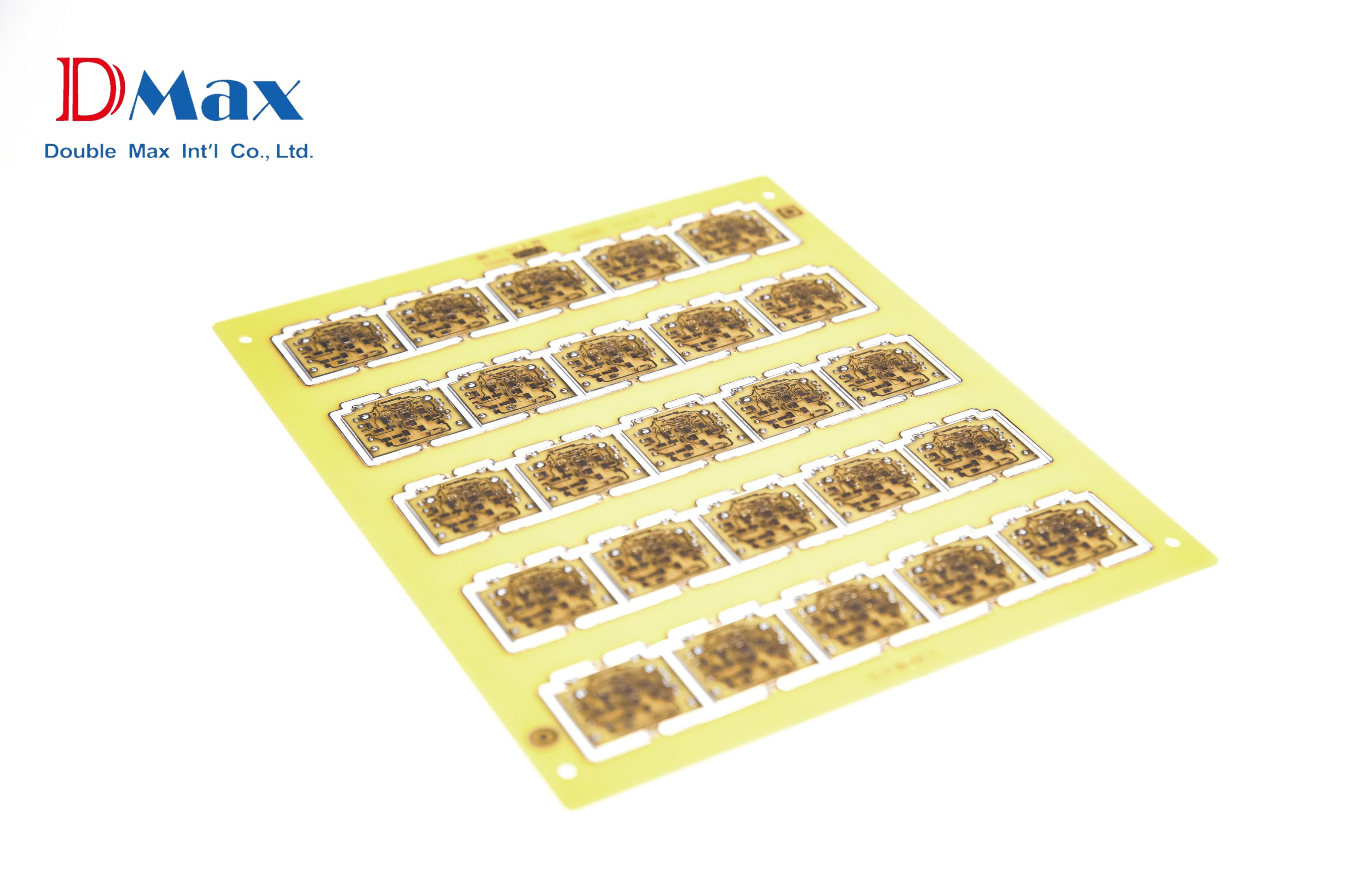

Multilayer and HDI PCB assembly

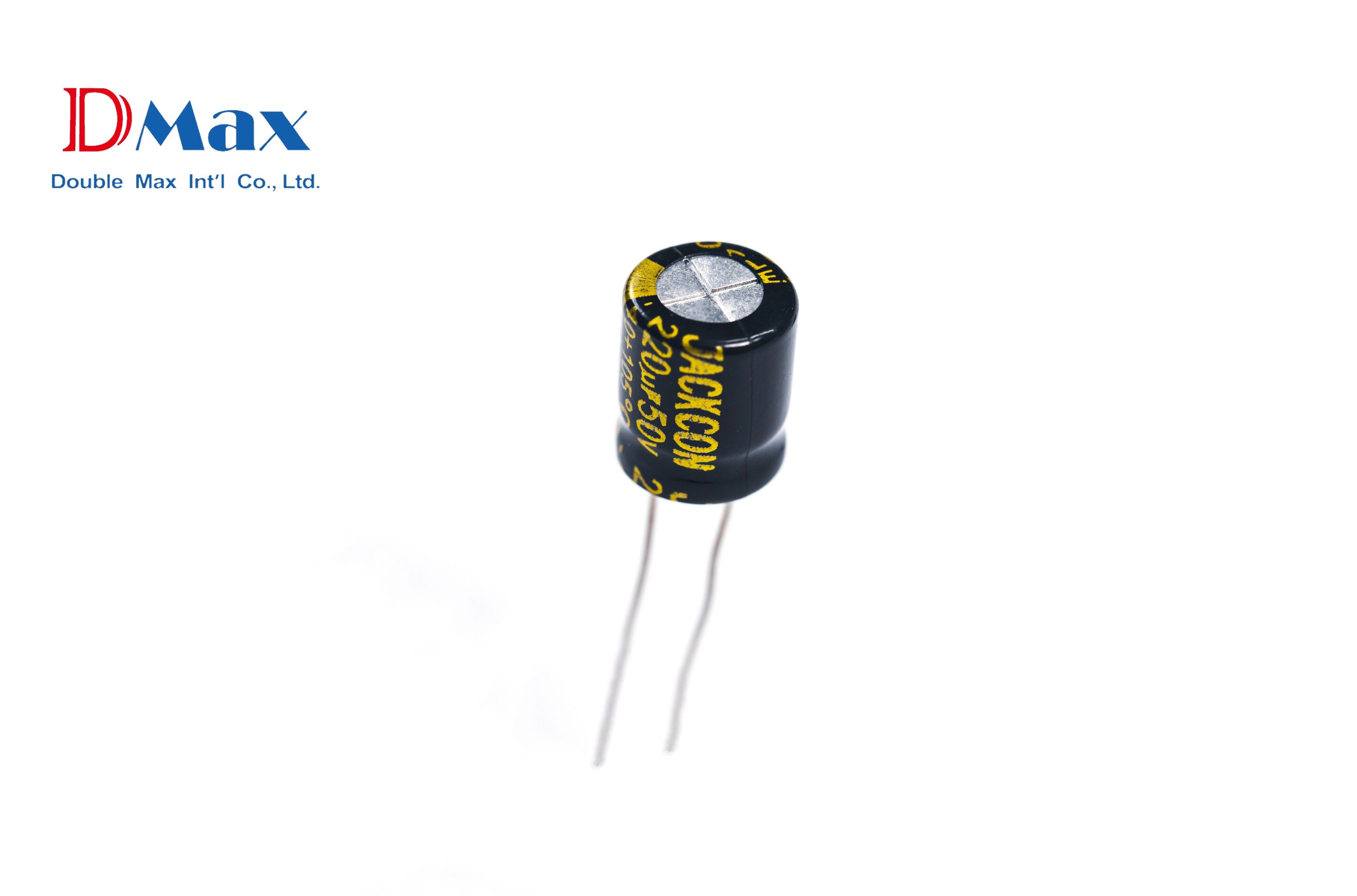

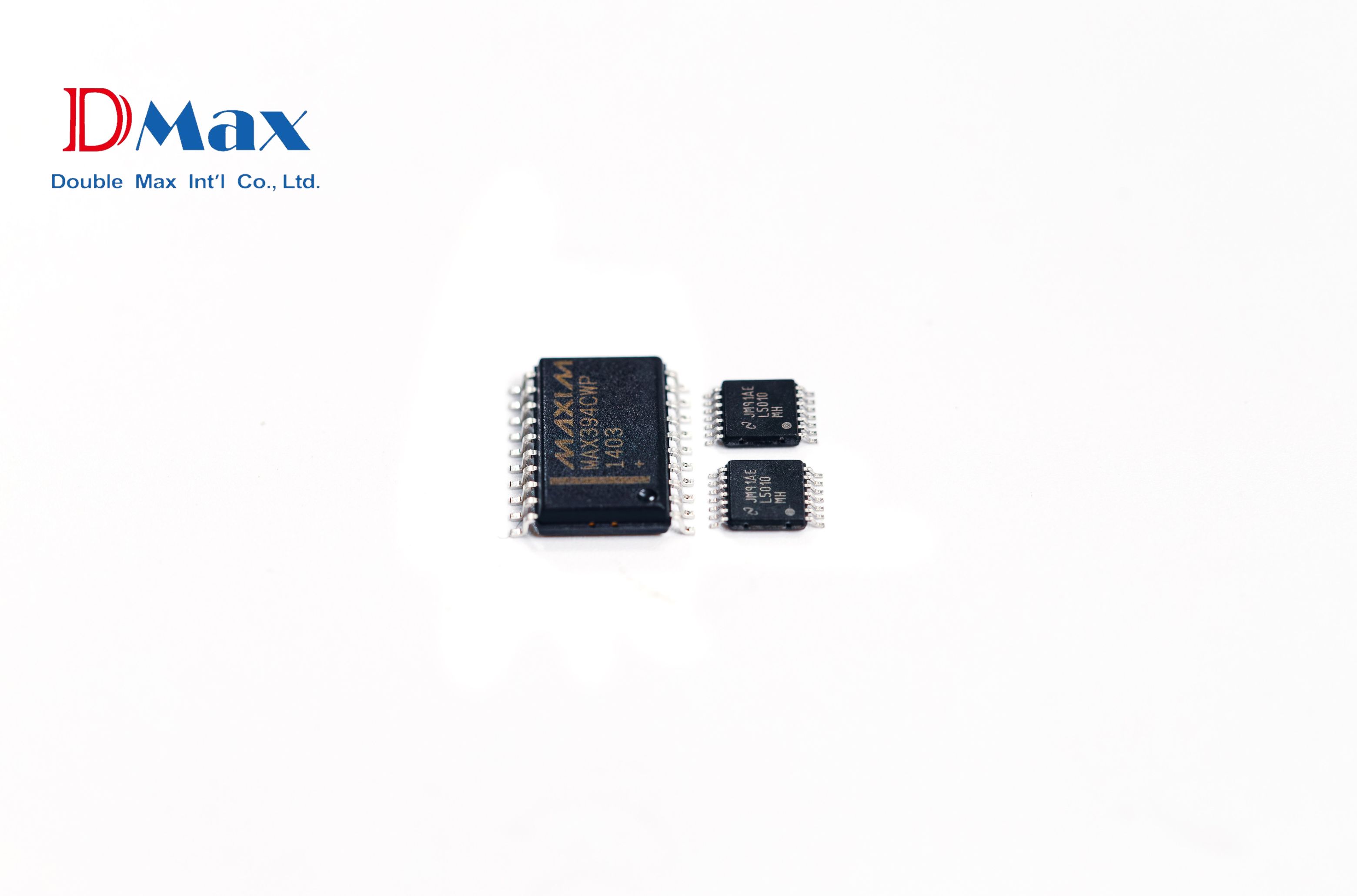

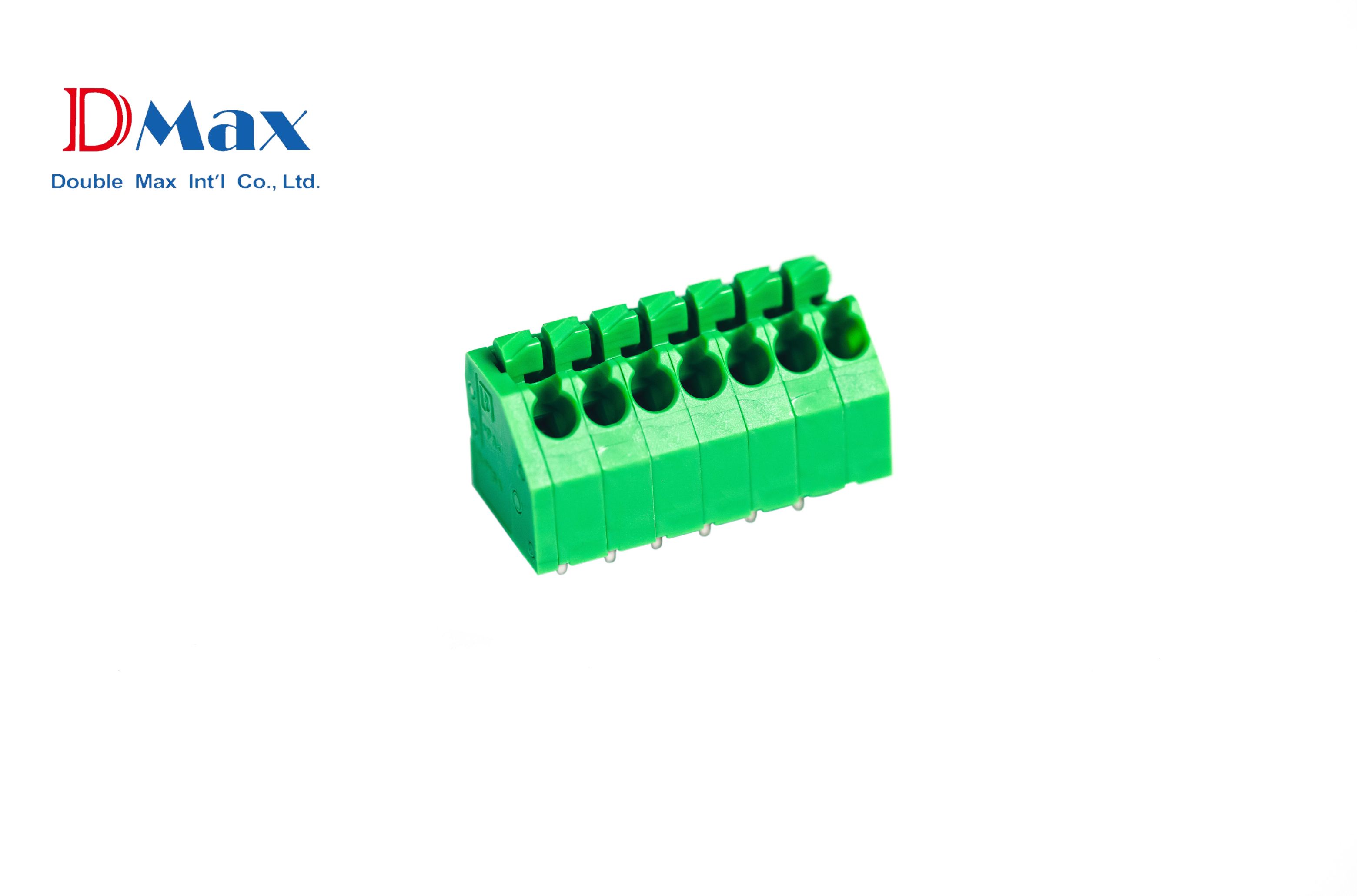

SMT and THT processes with fine-pitch component placement (0201, BGA, QFN)

ISO 9001 and IPC-A-610 compliant quality control

ISO 13485 readiness for medical-grade products

Flexible support for both prototyping and volume production

With a strong emphasis on reliability, traceability, and cross-industry experience, DMAX helps global B2B customers meet industry compliance standards and bring high-performance electronic products to market faster.

- Can a PCBA manufacturer support both prototyping and mass production?

- Which certifications should you verify when selecting a reliable PCBA manufacturer?

RECOMMENDATIONS

_2_cover.png)

_cover.png)