FAQ

Which certifications should you verify when selecting a reliable PCBA manufacturer?

Which certifications should you verify when selecting a reliable PCBA manufacturer?

When selecting a PCBA manufacturer, certifications are the primary indicators of PCBA quality stability, manufacturing reliability, and regulatory compliance. Working with internationally certified PCBA suppliers helps mitigate supply‑chain risks and ensures products meet industry standards. Common certifications to look for include ISO 9001, ISO 13485, IATF 16949, UL, IPC‑A‑610, and RoHS/REACH. This guide explains the relevance of each certification and helps B2B buyers worldwide identify the ideal PCBA manufacturing partner.

🔹Why PCBA Manufacturer Certifications Matter

Certifications not only reflect a PCBA manufacturer’s commitment to quality and process control but also secure international market access. Certified PCBA suppliers can:

Ensure production batch consistency throughout the PCBA manufacturing process

Comply with international regulations (such as EU RoHS and US FDA)

Reduce PCBA manufacturing defects and recall risk

Boost trust and credibility with global B2B buyers

Meet the high‑reliability requirements of industries like medical, automotive, and aerospace

🔹Key Certifications Every Global B2B Buyer Should Evaluate

Quality Management Systems

ISO 9001: Ensures standardized and continuously improving PCBA manufacturing processes

ISO 13485: Essential for medical-grade PCBA, requiring strict traceability and quality control

IATF 16949: Critical certification for automotive-grade PCBAs, meeting AEC-Q100 process standards

Product Safety and Manufacturing Reliability

UL Certification: Guarantees electrical safety for PCBA products in the North American market

IPC-A-610: Defines acceptability of PCBA assemblies, with Class 2 for commercial products and Class 3 for high reliability sectors (medical, aerospace)

MIL-STD‑883: Required for military/aerospace PCBA in thermal and environmental testing

Environmental and Regulatory Compliance

RoHS: Restricts harmful substances in PCBA materials, mandated in EU imports

REACH: Monitors and manages chemical substances used in PCBA manufacturing

WEEE: Regulates the recycling and disposal of end-of-life PCBA-based products

🔹How to Verify Your PCBA Manufacturer’s Certifications

To ensure your PCBA partner is truly certified:

Request scanned copies of valid certificates, including issuing body and expiration dates

Confirm certification scope covers PCBA manufacturing, not just component trading

Ask for recent audit dates to ensure certifications remain current

Consider on-site audits, third-party reports, or factory visits when necessary

🔹Industry-Specific Certification Requirements for PCBA Manufacturers

Different industries have distinct standards and regulatory requirements when sourcing PCBA (Printed Circuit Board Assembly) services. To ensure compliance, functionality, and market access, B2B buyers must select PCBA manufacturers that hold relevant certifications tailored to the target sector.

Below is an overview of critical industry segments and the certifications most commonly required:

1. Consumer Electronics

Consumer electronics such as smartphones, tablets, smart home devices, and wearables demand high-speed, compact, and cost-effective PCBA solutions. While general manufacturing standards may suffice, safety and environmental compliance remain essential.

Required Certifications:

ISO 9001 (Quality Management System)

RoHS (Restriction of Hazardous Substances)

Recommended Additional Standards:

UL (Product safety certification for electrical/electronic components)

IPC-A-610 Class 2 (Acceptability of electronic assemblies – commercial grade)

2. Automotive Electronics

The automotive industry places exceptionally high demands on durability, vibration resistance, and thermal performance. Automotive PCBAs are expected to operate reliably over long periods in challenging environments.

Required Certifications:

IATF 16949 (Automotive Quality Management System)

AEC-Q100 (Stress testing qualification for automotive-grade integrated circuits)

Recommended Additional Standards:

IPC-6012DA (Qualification and performance specification for high-reliability automotive printed boards)

3. Medical Devices

Medical PCBA applications, including diagnostic equipment, monitoring systems, and wearable health devices, require stringent control over cleanliness, traceability, and long-term reliability. Compliance with health authority regulations is non-negotiable.

Required Certifications:

ISO 13485 (Medical device-specific quality management)

FDA Registration (for US-bound medical devices)

Recommended Additional Standards:

IEC 60601 (Electrical safety standard for medical electrical equipment)

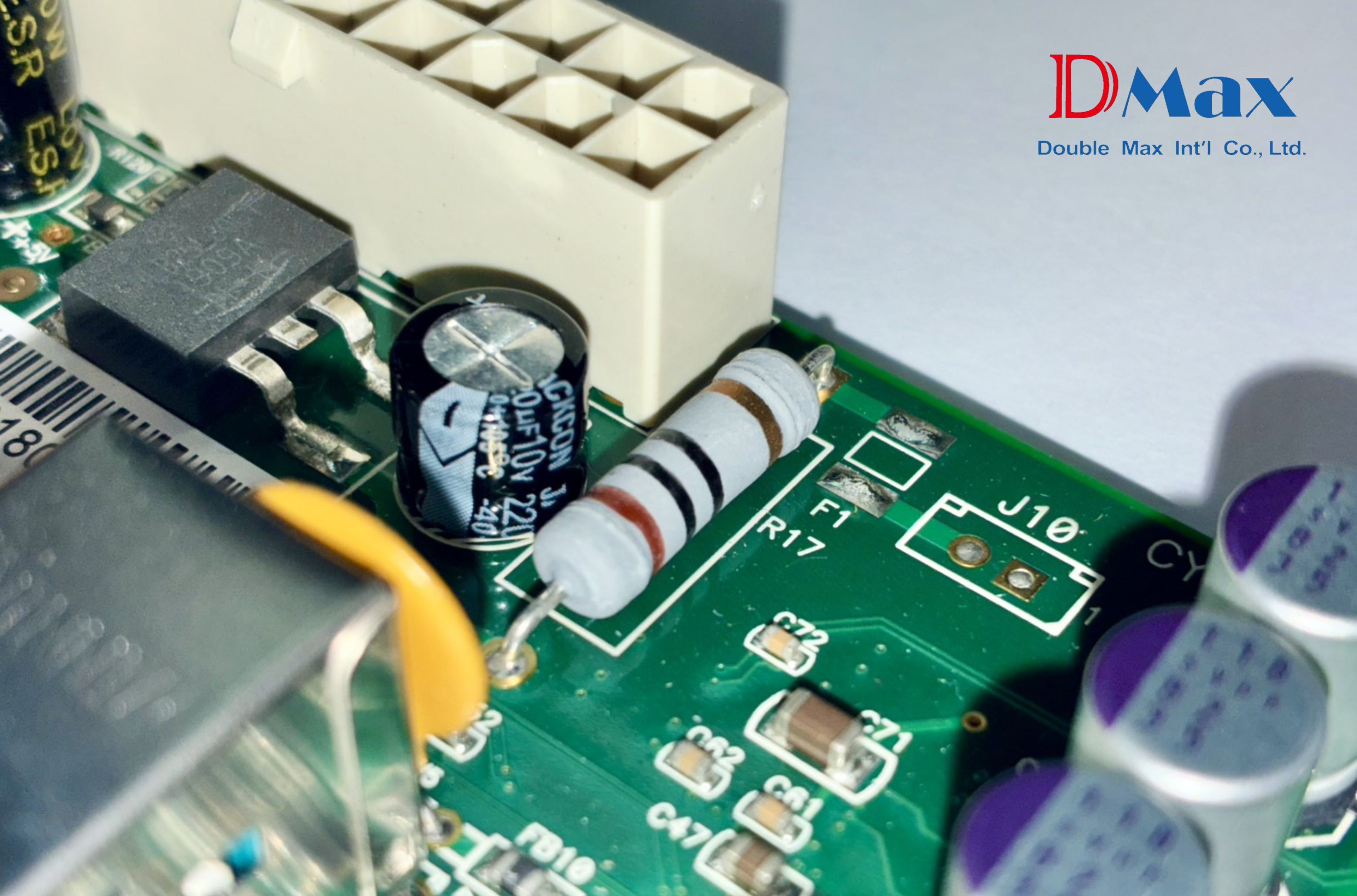

4. Industrial Control Systems

Industrial equipment such as PLCs, HMI interfaces, and sensors demand robust, long-lifecycle PCBA designs capable of performing under harsh industrial conditions.

Required Certifications:

ISO 9001 (Quality system for manufacturing control and consistency)

UL (Safety testing for electronic systems)

Recommended Additional Standards:

IPC-A-610 Class 3 (High-performance requirements for industrial and mission-critical applications)

5. Aerospace & Defense

This sector has some of the most demanding standards due to safety-critical applications in avionics, navigation, radar, and weapons control systems. Reliability under extreme environmental and operational conditions is paramount.

Required Certifications:

AS9100 (Aerospace Quality Management System)

MIL-STD-883 (Testing standard for microelectronic circuits in defense/aerospace)

Recommended Additional Standards:

NADCAP (Special process accreditation for procedures like soldering, conformal coating, etc.)

🔹Procurement Recommendations

Define your product category and target market regulations (EU CE, US FCC, etc.) clearly

Prioritize PCBA suppliers with multiple certifications, such as ISO 13485 + IATF 16949

Begin with a small PCBA prototype order to validate quality and lead time before committing to volume production

Confirm whether your supplier has traceability systems and provides technical support

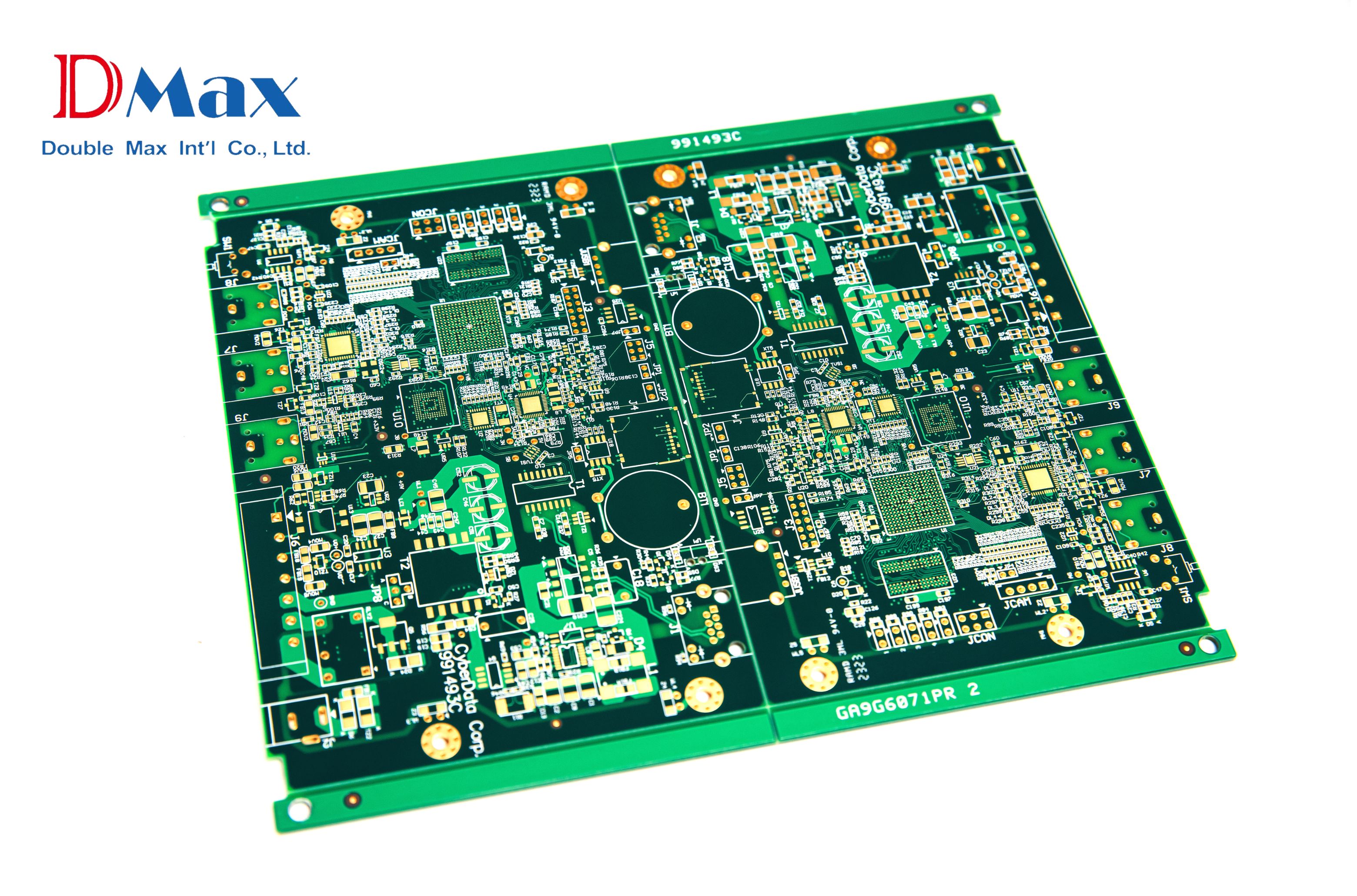

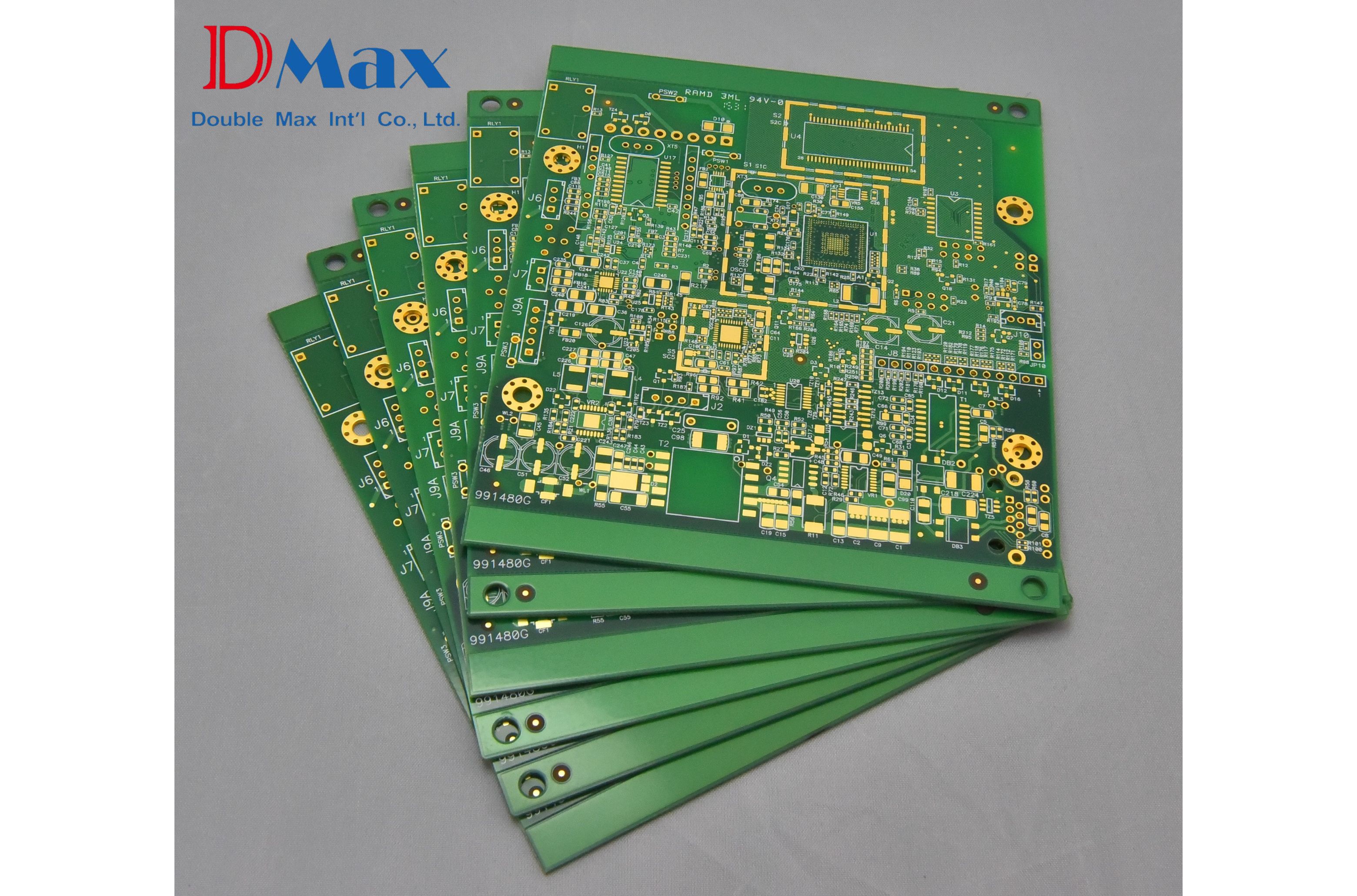

🔹DMAX: Internationally Certified PCBA Manufacturing Partner

DMAX is a Taiwan‑based PCBA manufacturer that meets global quality and regulatory standards. We hold the following credentials:

ISO 9001 quality management

Compliance with IPC‑A‑610 Class 2/3 assembly standards

Materials and processes certified for RoHS / REACH

Full inspection systems including IQC, IPQC, and OQC

Ability to deliver X‑Ray, AOI, functional test reports, and material certificates on request

With these capabilities, DMAX supports global customers through prototyping, trial production, and full volume PCBA manufacturing—meeting strict quality standards and regulatory requirements every step of the way.

- Which industries rely most heavily on PCBA manufacturing services?

- What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

RECOMMENDATIONS

_2_cover.png)

_cover.png)