FAQ

What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

Flexible Cooperation Models Offered by PCBA Manufacturers

To meet diverse supply chain needs, a PCBA manufacturer typically offers multiple cooperation models. From fully outsourced services to collaborative development and inventory management, these models help reduce cost, shorten lead time, and mitigate risks. Choosing the right model can greatly enhance manufacturing efficiency and market competitiveness.

Here are the five most common cooperation models in the PCBA industry:

1. Turnkey PCBA (Full-Service One-Stop Solution)

Turnkey PCBA refers to a comprehensive one-stop model where the PCBA manufacturer handles everything from BOM optimization, component procurement, PCB fabrication, SMT assembly, testing, to final logistics and support.

Best suited for:

Startups and SMEs

Companies lacking internal procurement or engineering resources

Projects requiring rapid time-to-market

Advantages:

Single point of contact and accountability

Streamlined management and faster production

Suppliers assume component sourcing and inventory risk

Points to note:

Carefully evaluate the supplier's sourcing capabilities

Consider fixed-cost agreements to hedge against price fluctuations

2. Consignment (Customer-Supplied Material Model)

In this model, the customer provides all or key materials, while the PCBA manufacturer focuses on assembly and testing. This is ideal for companies needing strict control over materials or that have access to strategic sourcing channels.

Best suited for:

Enterprises with stable in-house procurement systems

Projects requiring specific or long-lead-time components

Cost-sensitive initiatives

Advantages:

Full control over material quality and cost

No markup from the manufacturer

Ideal for clients with existing supplier relationships

Points to note:

Buyer assumes material management and obsolescence risks

Clear material loss responsibility should be established

3. Partial Turnkey (Hybrid Model)

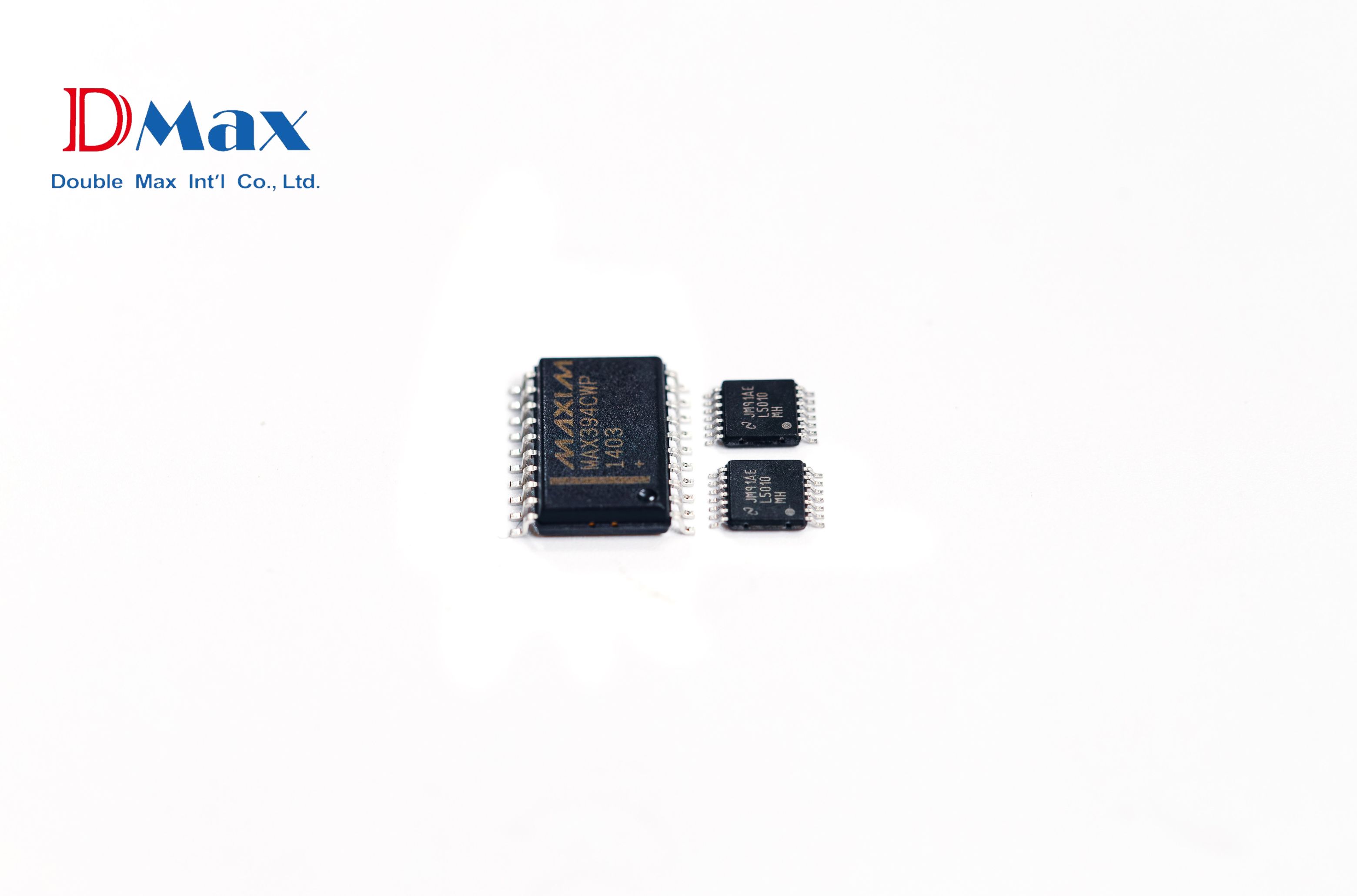

Partial Turnkey allows shared responsibility between the buyer and the PCBA manufacturer. For example, the client may supply critical ICs, while the manufacturer handles the PCB, assembly, and testing processes.

Typical responsibility division:

| Client Responsibility | Manufacturer Responsibility |

|---|---|

| Key IC procurement | PCB manufacturing + SMT |

| Firmware programming | Functional testing |

| Casing assembly | Aging & reliability testing |

Best suited for:

Companies with selective sourcing advantages

Phased transition from in-house to outsourced production

Projects requiring a balance between cost control and flexibility

4. ODM / JDM (Collaborative Development Models)

These models are ideal for clients requiring involvement from the PCBA manufacturer during the R&D phase, especially in high-tech sectors like medical, automotive, or telecom.

ODM (Original Design Manufacturing): Manufacturer provides reference designs and handles full production; client adds branding and custom features.

JDM (Joint Design Manufacturing): Client provides product concept while the manufacturer contributes engineering and design expertise. IP may be co-owned.

Benefits:

Reduces development cycles by 30–50%

Minimizes NRE (non-recurring engineering) costs

Access to manufacturer’s technical ecosystem and experience

5. VMI (Vendor Managed Inventory)

In this model, the PCBA manufacturer manages inventory based on demand forecasts. Materials are stocked in advance, and production is triggered by real consumption.

Best suited for:

- Long-term, stable OEM projects

- Clients able to share sales forecasts

- Systems with EDI integration for real-time coordination

PCBA Cooperation Model Comparison & Strategic Selection

| Model | Buyer Involvement | Risk Ownership | Lead Time | Cost Control |

|---|---|---|---|---|

| Turnkey | Low | Manufacturer | Fast (4–6 wks) | Medium (service fee included) |

| Consignment | High | Buyer | Moderate (6–8 wks) | High (no markup) |

| Partial TK | Shared | Shared | 5–7 wks | High (customizable) |

| ODM / JDM | Technical input | Shared | 8–12 wks | Long-term benefits |

Procurement Decision Tips

Evaluate your internal capabilities: Do you have sourcing engineers? Technical staff? Capital efficiency?

Match model to product type: Standardized products work well with Turnkey; highly customized projects are better suited for JDM.

Risk diversification strategy: For key products, consider using a “primary Turnkey + secondary Consignment” dual-track system.

DMAX’s Professional Support for All PCBA Cooperation Models

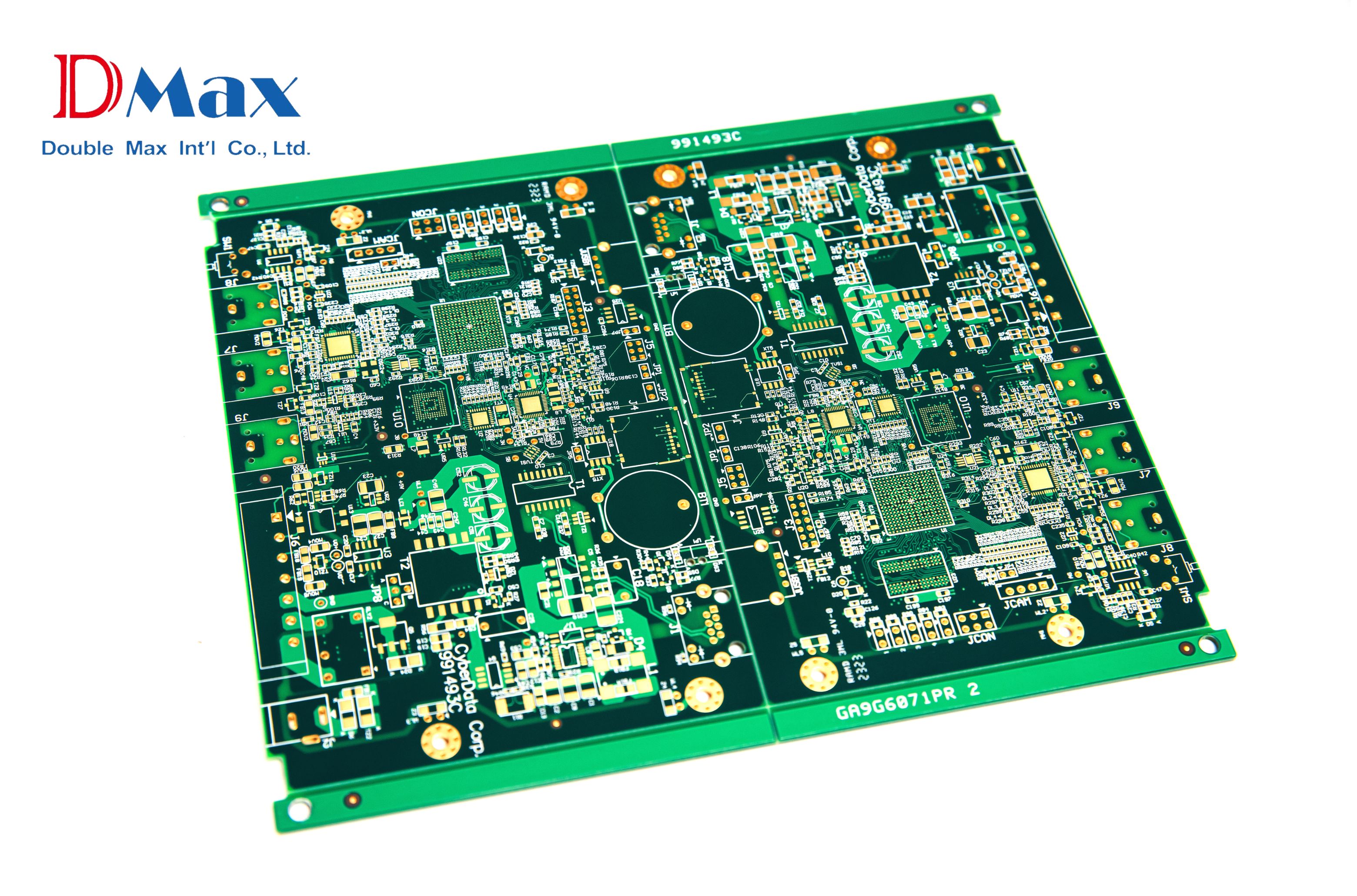

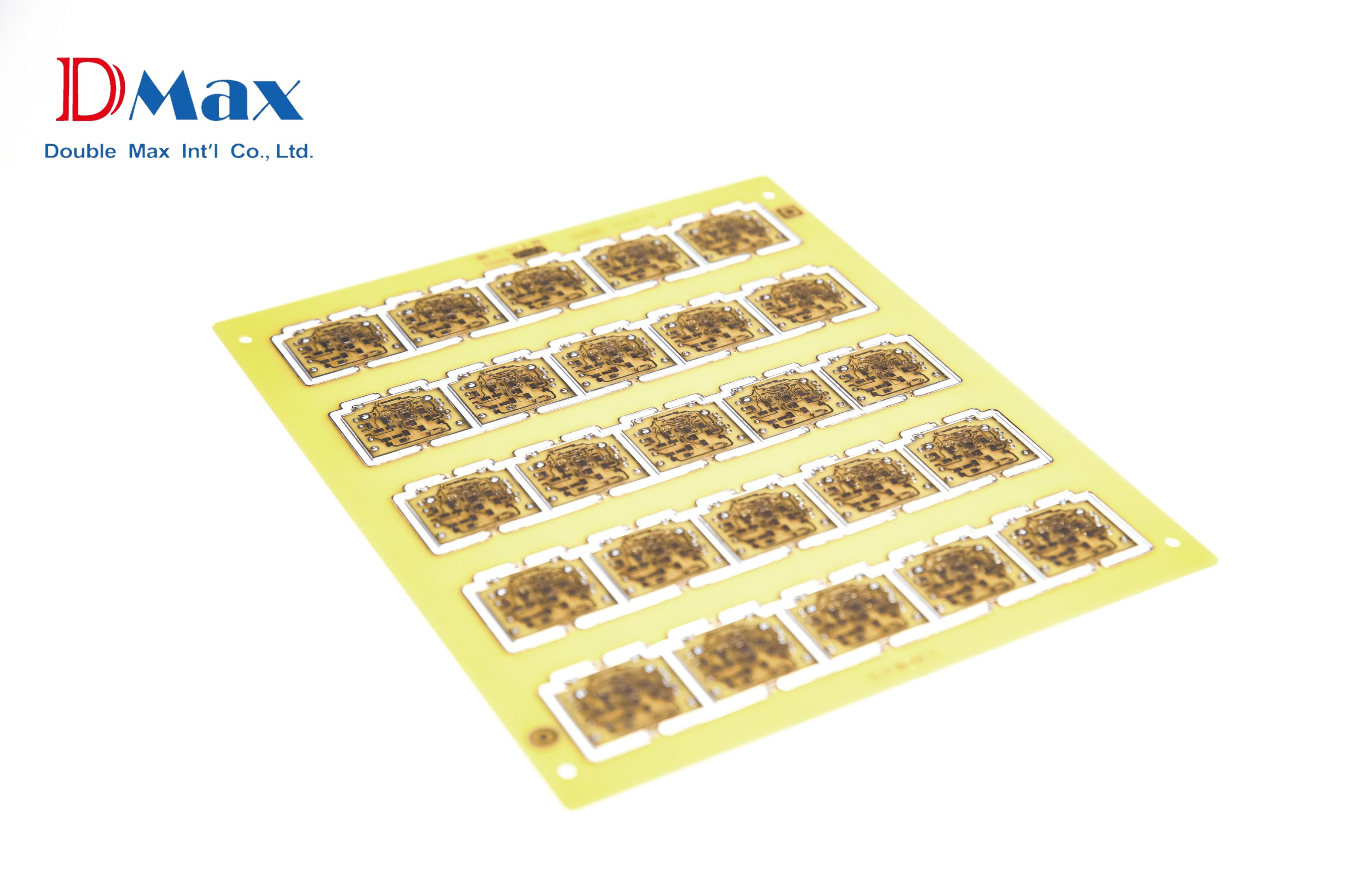

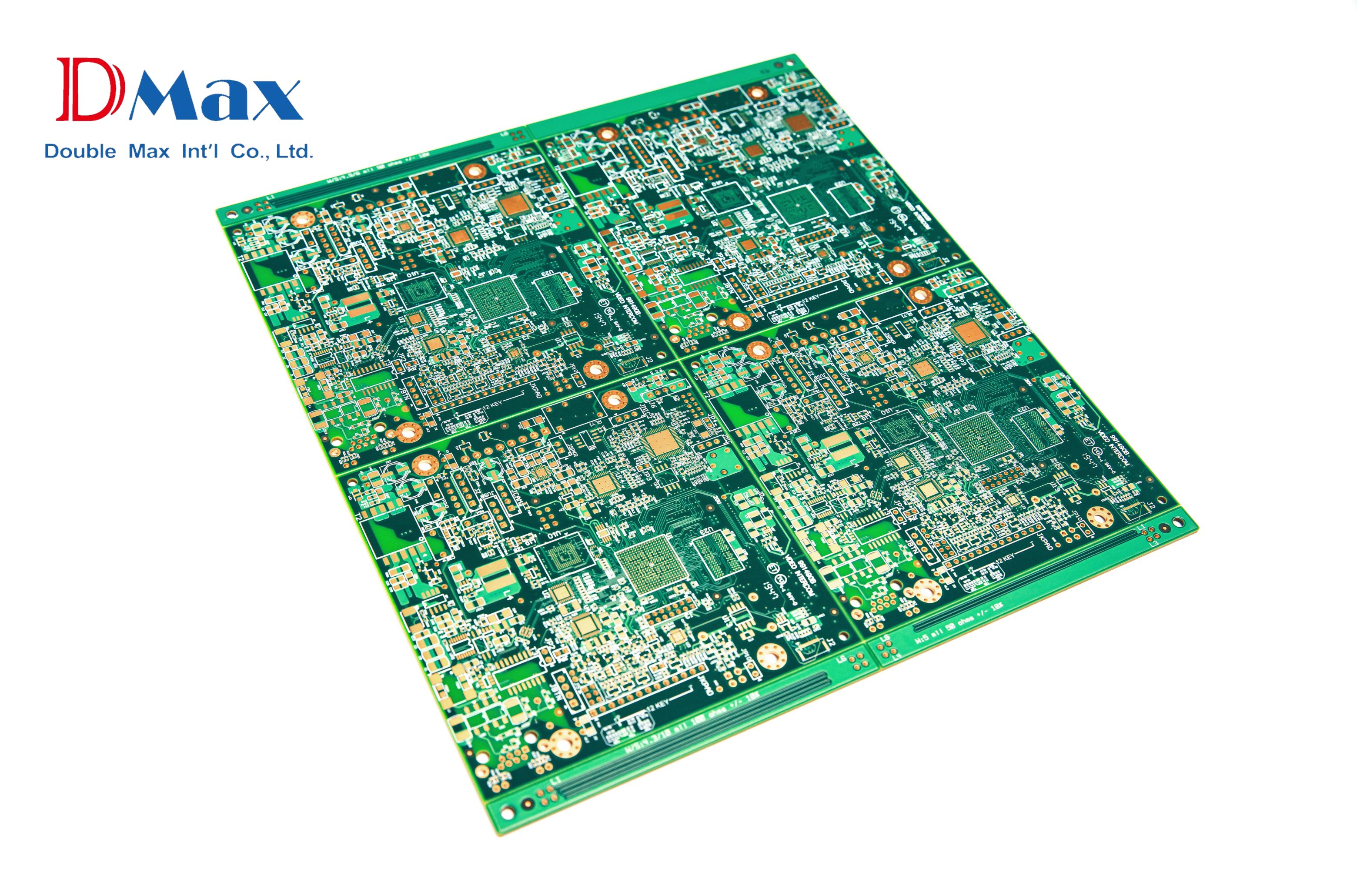

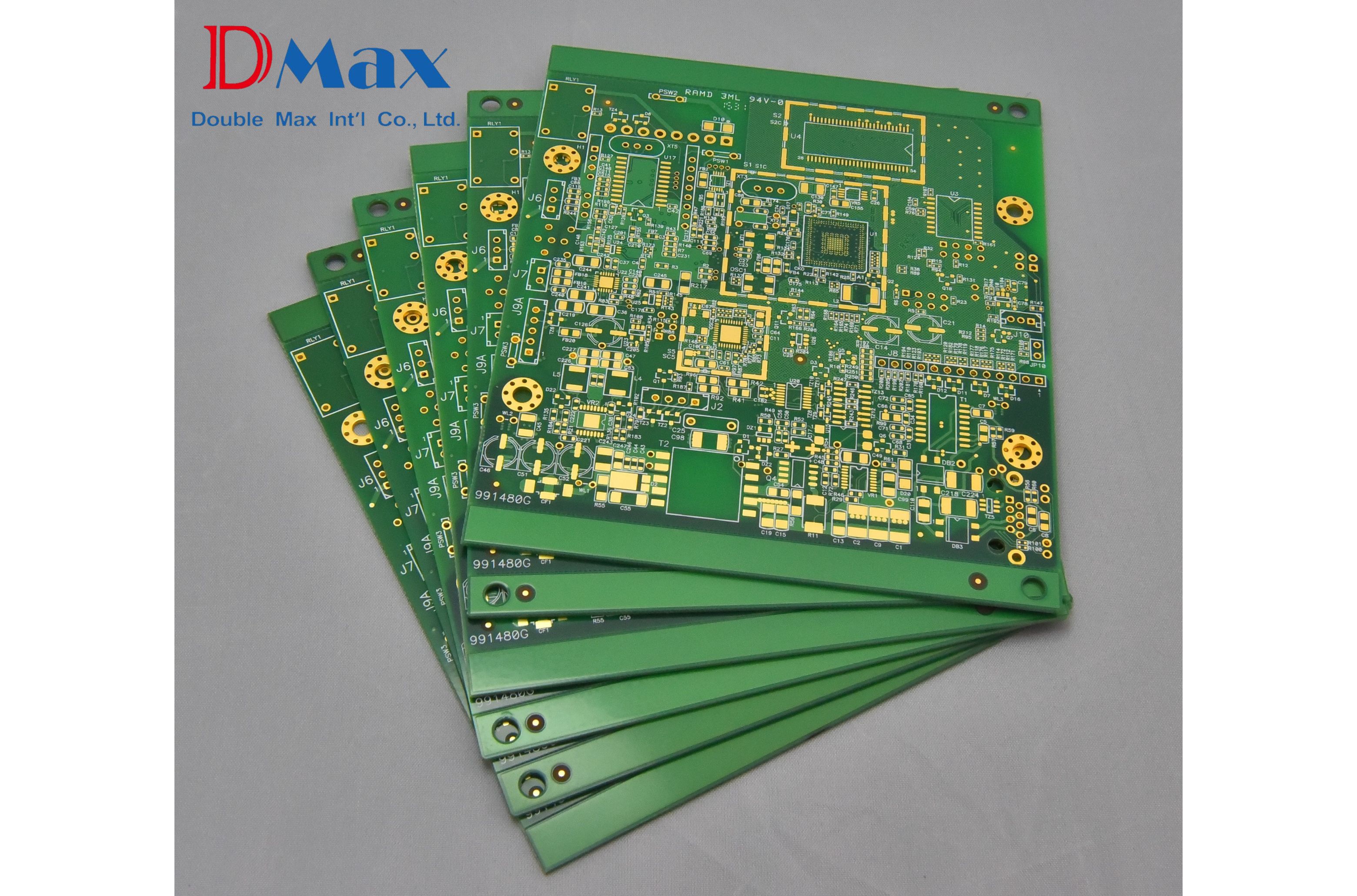

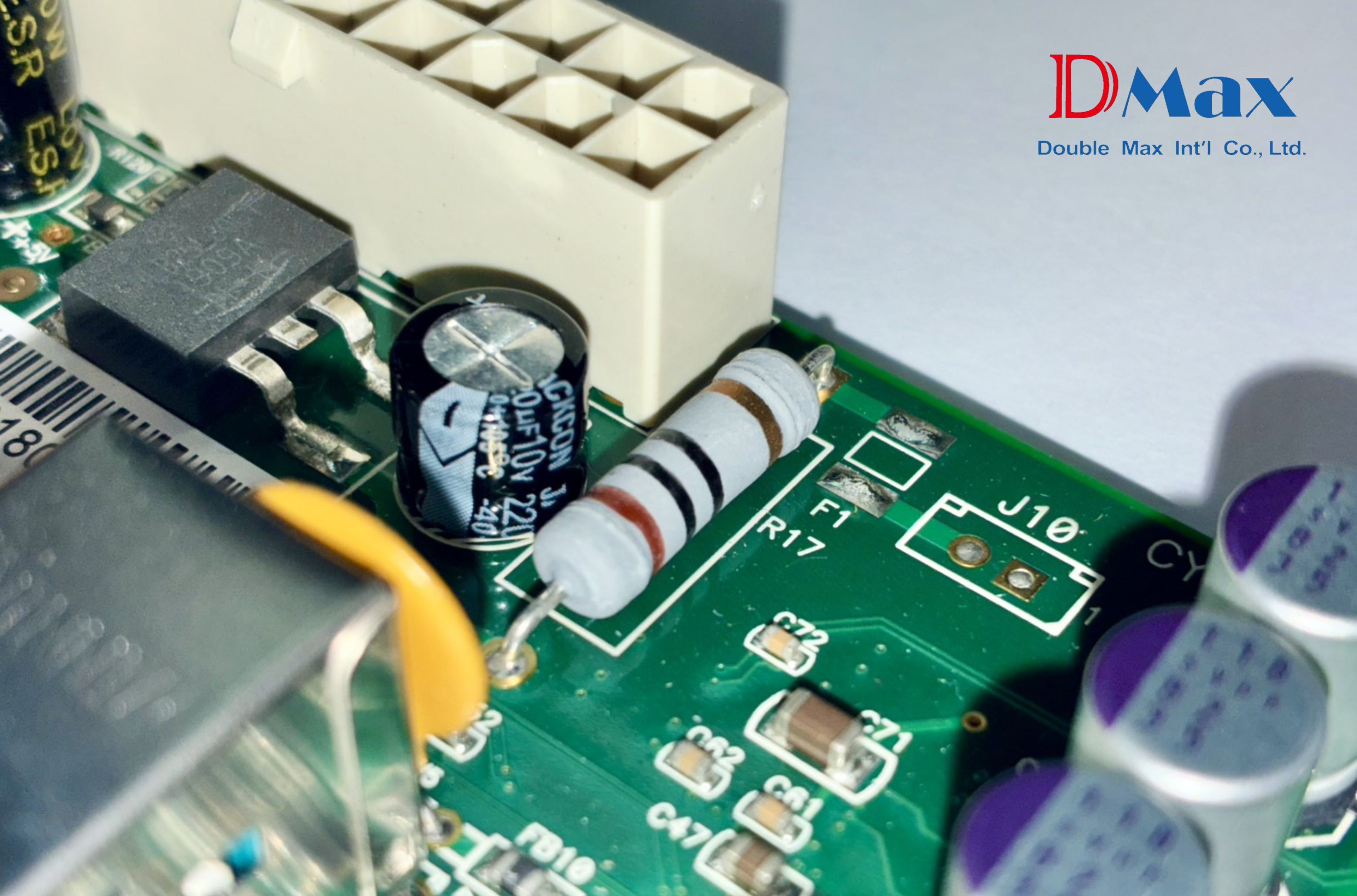

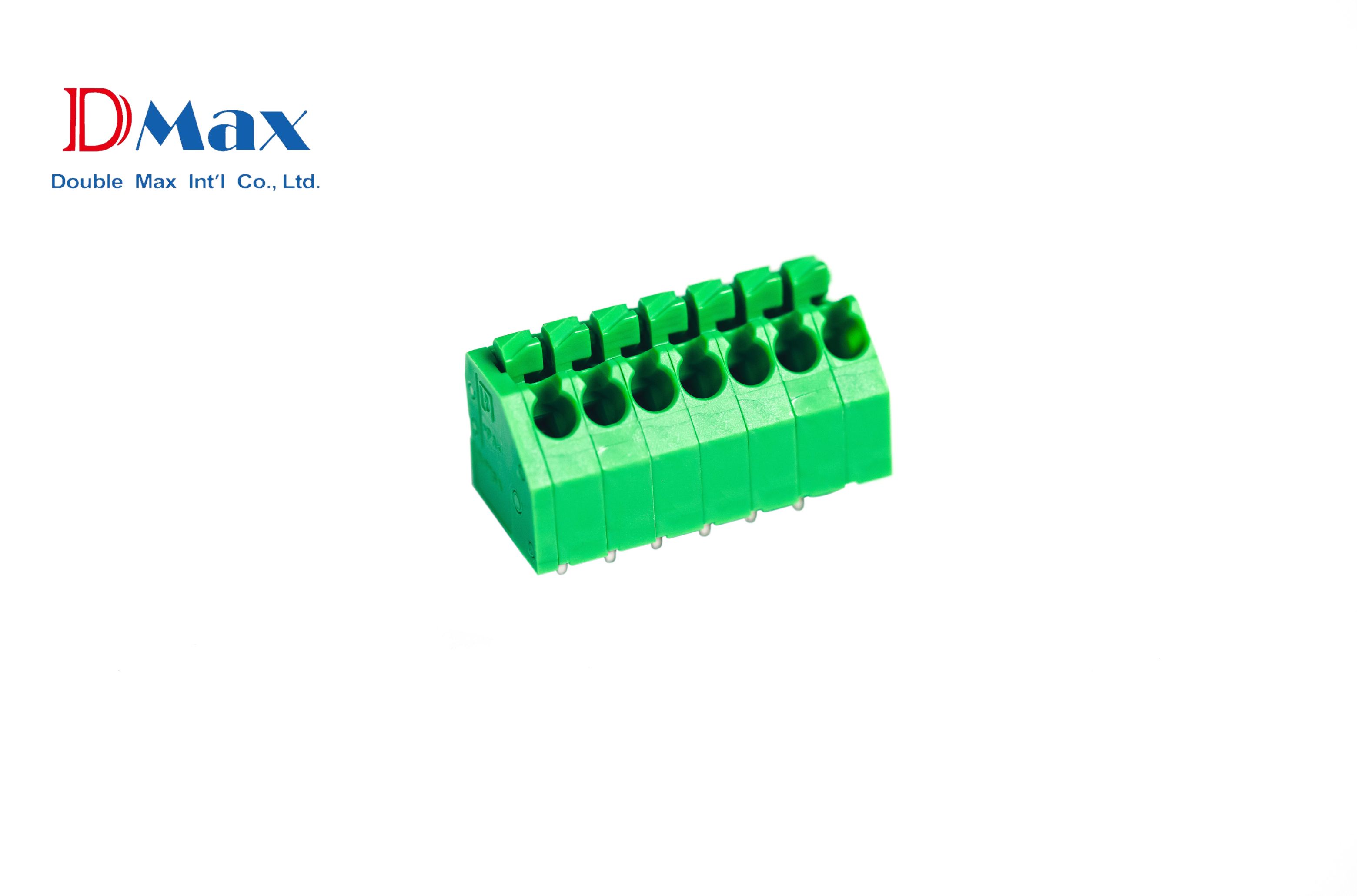

As a trusted PCBA manufacturer in Taiwan, DMAX offers comprehensive solutions, including:

Full-service Turnkey PCBA for hands-off execution

Flexible Consignment and Partial Turnkey options

ODM / JDM collaboration for R&D-intensive projects

Support for VMI to enhance inventory responsiveness

DMAX is ISO-certified, RoHS-compliant, and adheres to IPC Class 2/3 assembly standards. From prototyping to mass production, DMAX delivers scalable, high-reliability PCBA services for global B2B clients.

RECOMMENDATIONS

_2_cover.png)

_cover.png)