FAQ

What is a PCBA?

What is a PCBA?

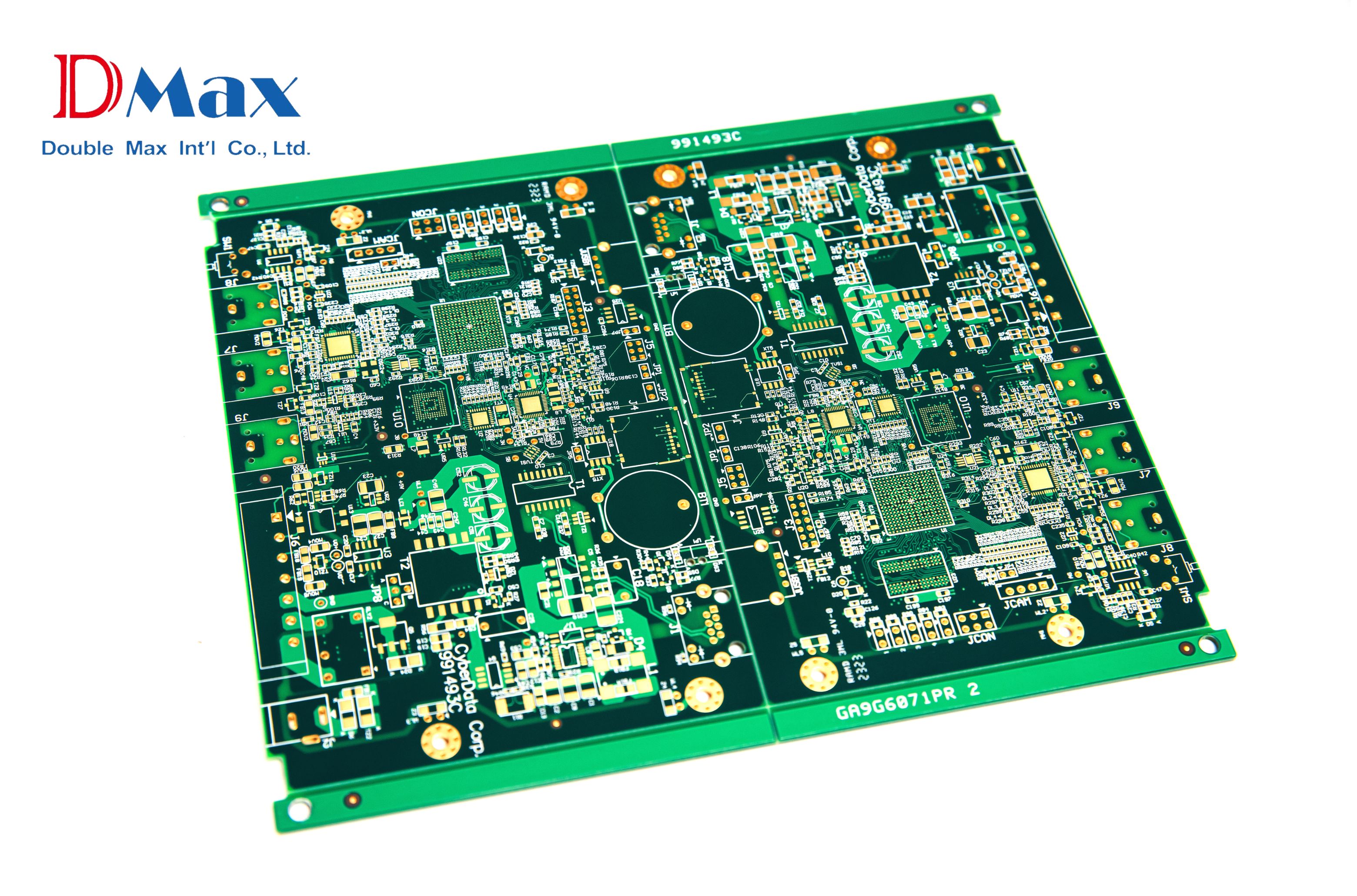

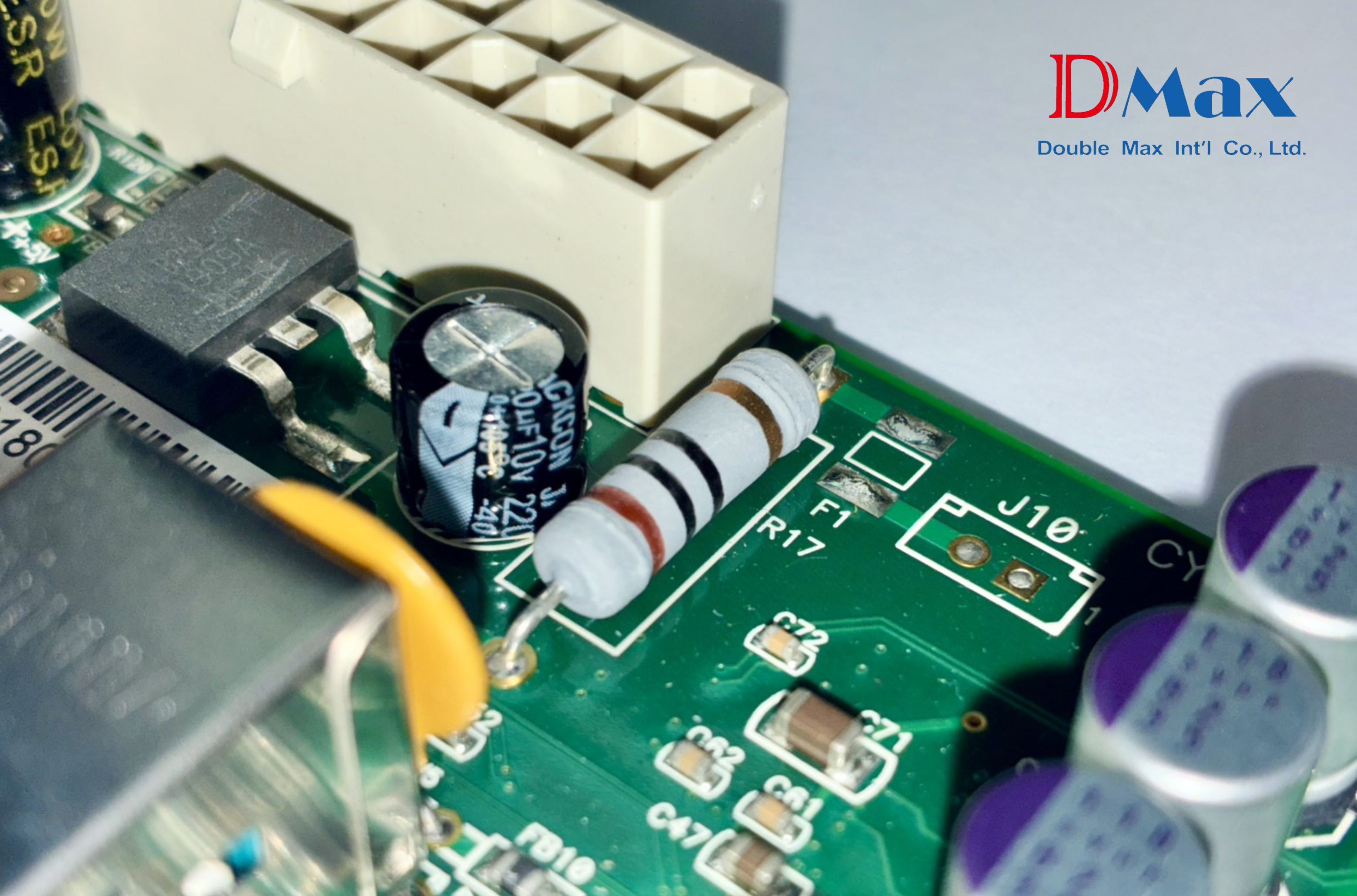

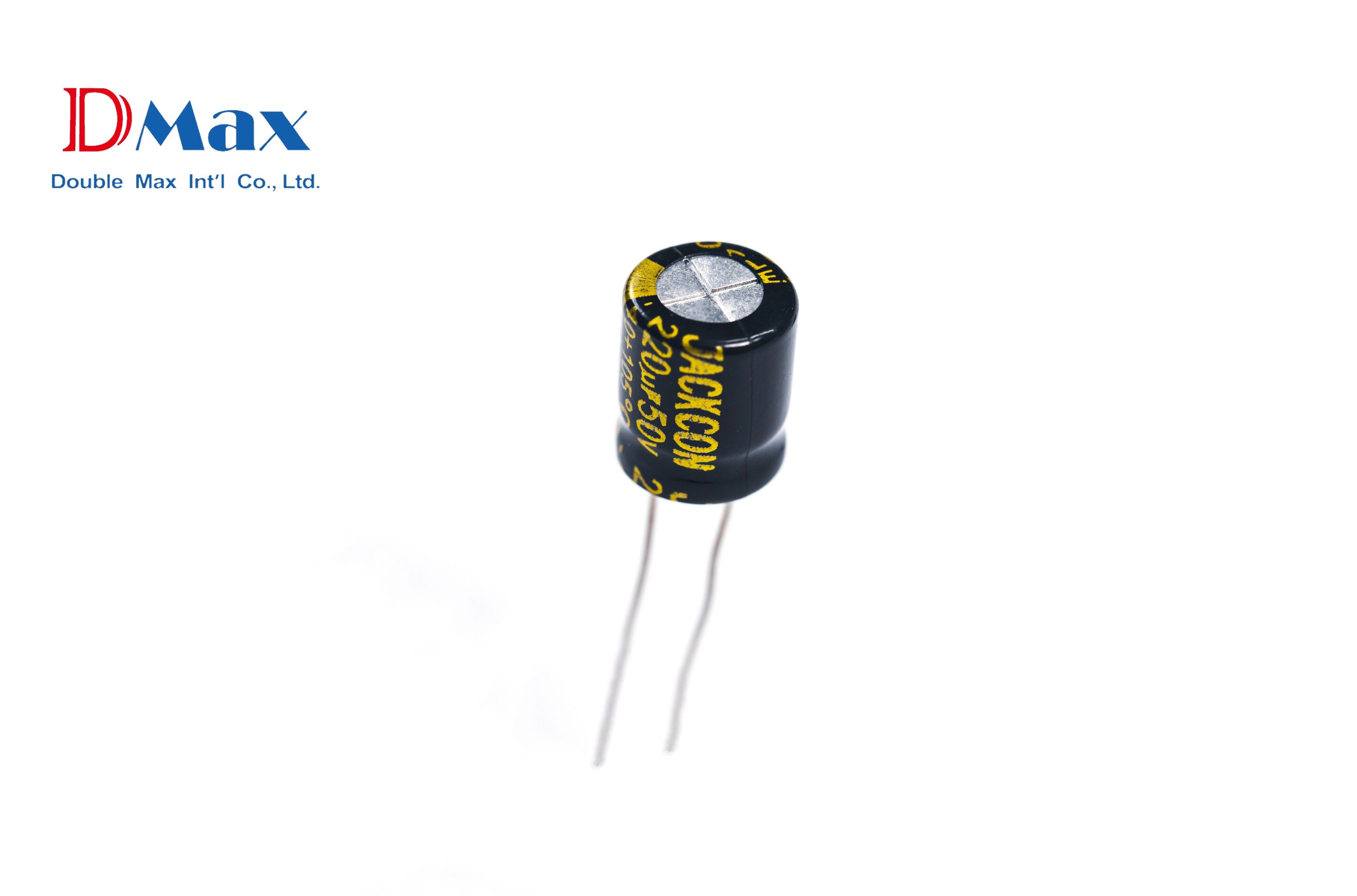

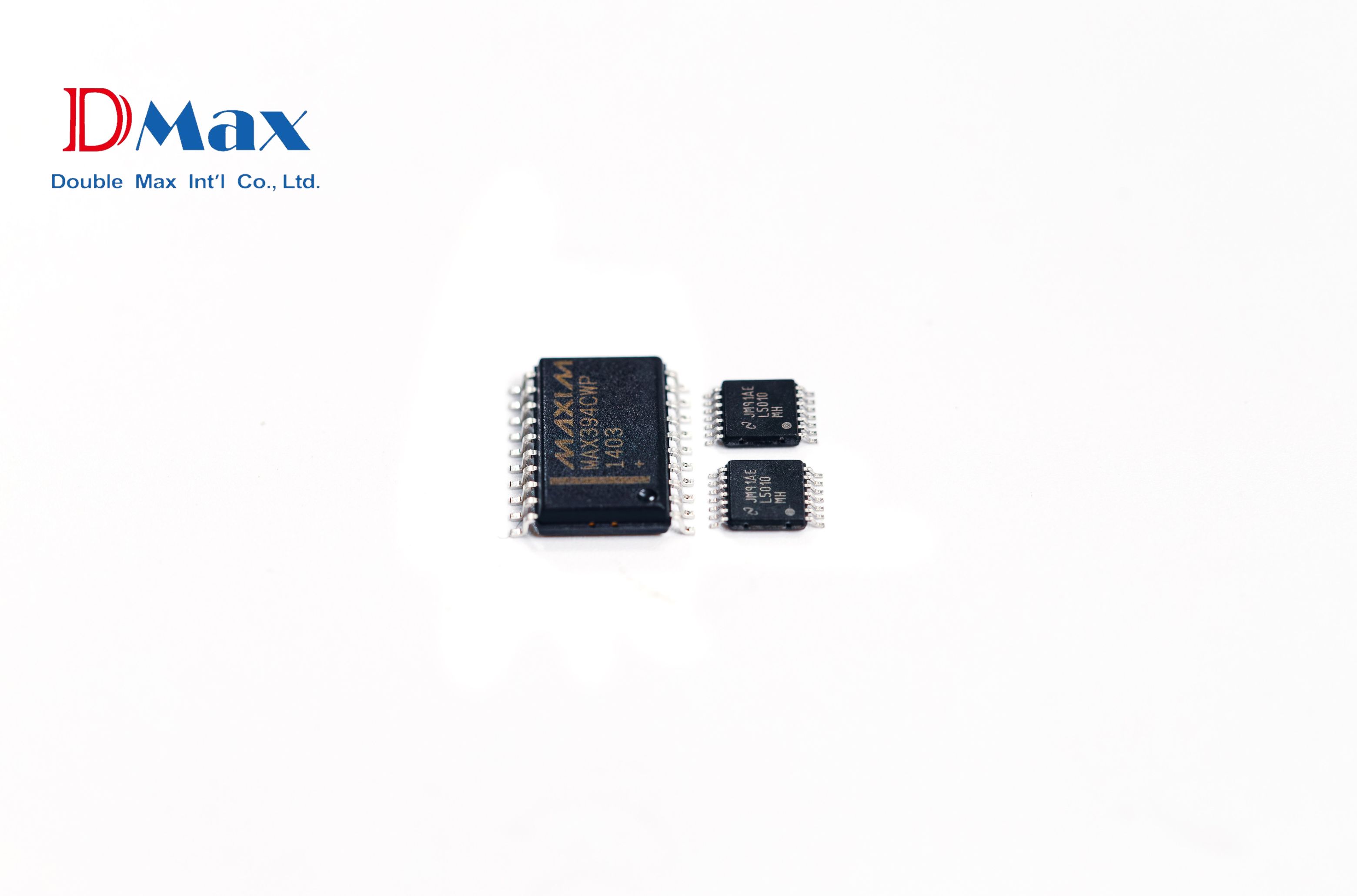

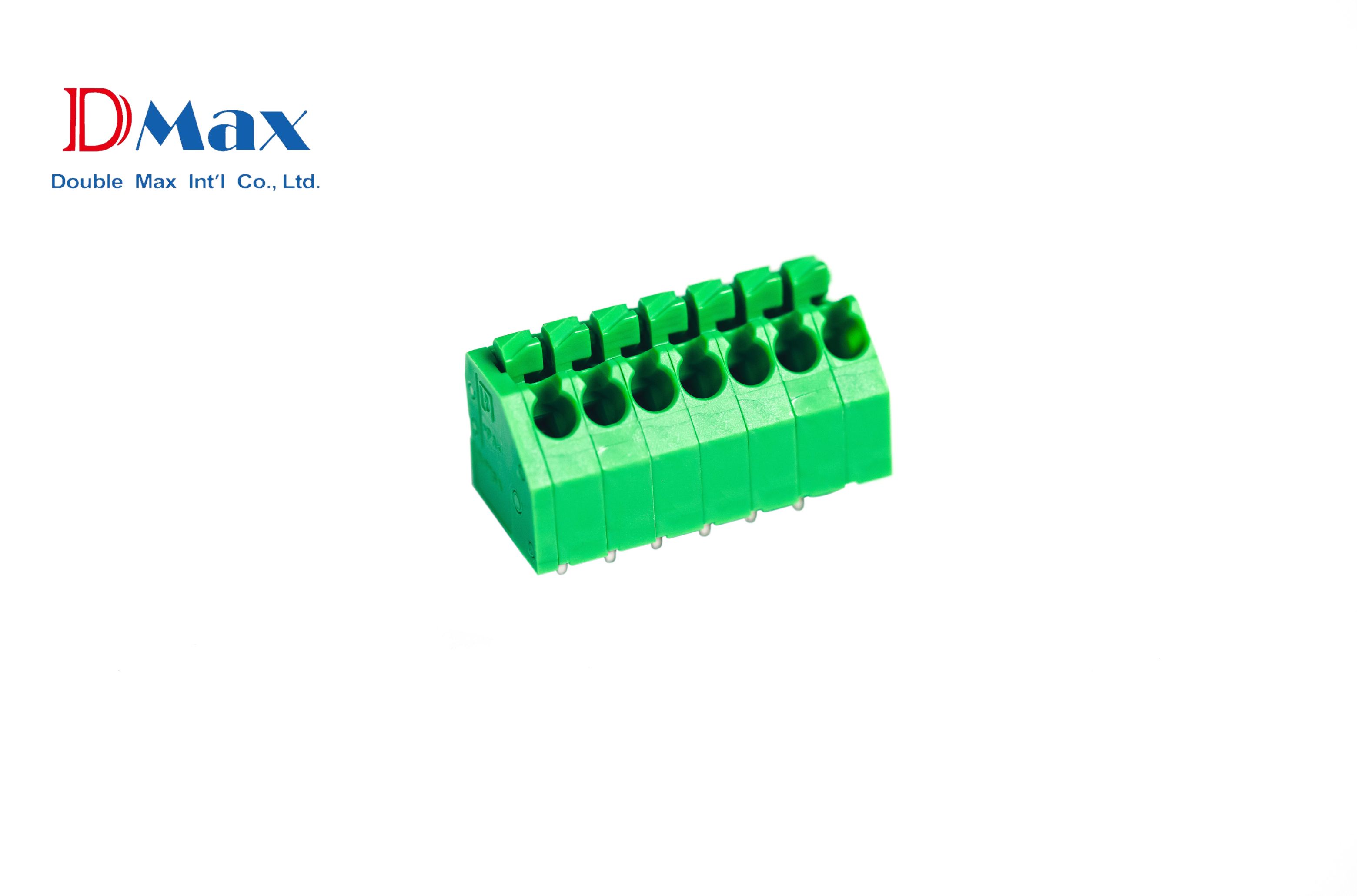

PCBA stands for Printed Circuit Board Assembly. It refers to the "functional circuit board" that is completed after all electronic components (such as ICs, resistors, capacitors, etc.) have been mounted and soldered onto a "bare circuit board."

Simply put, a PCBA is a "functional" board that, once powered, can execute specific electronic functions.

PCBAs are used in all modern electronic products, such as computers, mobile phones, medical devices, and industrial controllers. In any electronic product, the PCBA is the"vital heart" that enables the device to operate.

- Common Aliases: Assembled Board, Finished Board, Mounted Board.

- Status: A PCBA starts with a bare PCB (bare board) and undergoes professional processes like SMT or DIP to "Assemble" and "Solder" all necessary electronic components (like ICs, resistors, capacitors) onto it, resulting in a "functional circuit board."

- Function: A PCBA is a board with specific capabilities. When powered, it executes computations, controls, or signal conversions. It is the "vital heart" that drives electronic products.

What are the core functions of a PCBA?

1. Executing Computation and Control

Core chips (like CPUs, MCUs) on the PCBA are responsible for receiving instructions, processing data, and sending control signals.

For example: The PCBA in a computer motherboard runs the operating system; the PCBA in an air conditioner controls the compressor based on signals from the remote.

2. Processing and Converting Signals

The PCBA manages all incoming and outgoing signals.

For example: A PCBA can convert analog audio signals from a microphone into digital signals; it can also decode data signals from a network cable to display images on a screen; or it can convert high-voltage AC power into low-voltage DC power.

3. Providing System Interfaces

Through connectors, the PCBA acts as the bridge between the product's "internal" electronics and the "external" world.

For example: A PCBA allows users to operate a device via inputs (like USB, HDMI, or buttons) and enables the device to respond via outputs (like screens, speakers, or motors).

4. Providing Reliable Electrical Connection and Physical Support

A high-quality PCB is the prerequisite for a stable PCBA. D-MAX's high-quality assembly process is the key method to "realize" this solid foundation into an even more stable and reliable PCBA, ensuring that the connections on the PCBA remain stable and reliable under vibration, high temperatures, or long-term use.

What industries use PCBAs?

The application range of PCBAs covers almost every modern industry. Essentially, any electronic device that requires "electricity" and needs to perform specific "smart functions" will contain a PCBA. The PCBA is the heart of all electronic products, responsible for driving all computation, control, sensing, and communication functions.

Different industries have vastly different and strict requirements for a PCBA's functionality, stability, and durability. Below are some of the core fields where PCBAs are most widely used:

1. Industrial Automation and Control

-

Applications: Factory PLCs (Programmable Logic Controllers), CNC machines, robotic arms, frequency inverters, industrial sensors.

-

Role of the PCBA: In the industrial sector, PCBAs must withstand harsh factory environments, including high temperatures, high humidity, vibration, and dust. The PCBAs in these electronic devices need to operate stably 24/7 without interruption, executing precise motor control, reading sensor data, and ensuring production line safety. Therefore, high-reliability and durable PCBAs are an absolute requirement in this field.

2. Medical Devices

-

PCBA Applications: ECG (Electrocardiogram) machines, oximeters, ultrasound scanners, ventilators, precision surgical-assist instruments.

-

Role of the PCBA: Medical-grade PCBAs are life-critical, demanding extremely high precision and zero-failure reliability. The PCBAs used in this sector must be high-precision, responsible for processing faint physiological signals and performing accurate diagnostic computations.

3. Automotive Electronics

-

PCBA Applications: ECUs (Engine Control Units), ADAS (Advanced Driver-Assistance Systems), BMS (Battery Management Systems), in-vehicle infotainment systems.

-

Role of the PCBA: Automotive-grade (auto-grade) PCBAs operate in the most extreme environments. PCBAs operating in automotive devices must withstand drastic temperature changes (from severe cold to high engine heat) and continuous driving vibrations, all while performing real-time computations related to vehicle safety. Therefore, PCBAs in automotive electronics require an extremely high degree of stability.

4. Consumer Electronics

-

PCBA Applications: Smartphones, laptops, smartwatches, wireless earbuds, smart home appliances.

-

Role of the PCBA: The challenge for PCBAs in this sector is to be "light, thin, short, and small." The PCBA must integrate multiple functions—such as high-speed computing, graphics processing, wireless communications (Wi-Fi, 5G), and power management—into an extremely limited space. Consequently, this industry has a very high demand for high-density assembly processes for its PCBAs.

5. Communications and Networking

-

PCBA Applications: 5G base stations, servers, network switches, routers.

-

Role of the PCBA: These devices require the PCBA to handle massive volumes of high-speed data transmission. Therefore, PCBAs used in this field require complex multi-layer designs and must ensure excellent high-frequency signal integrity to achieve stable, low-latency network communication.

From the application examples and fields above, it's clear that PCBAs are ubiquitous in modern life. Regardless of your product's sector, you need a PCBA assembly partner who deeply understands the specific demands of that industry.

D-MAX specializes in providing high-quality, high-reliability PCBA manufacturing services. We are dedicated to building a stable PCBA for your product, ensuring it can perfectly deliver its intended performance and operate reliably long-term.

How should PCBA components be selected?

The selection of PCBA components is the most critical core step in determining a PCBA project'scost, lead time, and final reliability.

The selection of electronic components for a PCBA is not just a technical specification issue for R&D engineers; it is astrategic issue that B2B procurement and manufacturing departments must jointly address. A poorly planned PCBA component list (BOM) will lead to project delays, cost overruns, or future mass production instability.

When you are designing your product and creating your BOM (Bill of Materials), D-MAX strongly recommends considering the following four aspects:

- Meet Technical Specifications (Functional Fit) Meeting technical specifications is the foundation and the critical first step in selecting PCBA components. The variouselectrical characteristics (e.g., voltage, current, resistance, capacitance, precision) andphysical characteristics (e.g., size, operating temperature range) of the PCBA components must be carefully selected to perfectly match your product's design requirements. D-MAX's professional team will assist you in reviewing these PCBA component specifications to ensure the selected components perfectly meet your product's design and functional needs.

- For example: For an industrial control PCBA, its components must be"industrial-grade" parts capable of withstanding -40°C to 85°C, not "commercial-grade" parts rated for only 0°C to 70°C.

2. Supply Chain Stability

This is the most easily overlooked point in B2B procurement of PCBA components. Selecting a PCBA component that is out of stock or has an excessively long lead time is more fatal than choosing the wrong specification.

-

Lead Time: When selecting PCBA components, priority must be given to standard, "mainstream" parts with a stable supply. Avoid selecting exclusive or niche PCBA components with lead times stretching over 52 weeks, as this will severely impact the PCBA production schedule.

-

Second Source: Critical PCBA components (especially ICs) must not have only a single supplier. Your PCBA BOM should, as much as possible, list 2-3 verified "PCBA alternate part numbers" to cope with global parts shortages.

-

Cost & MOQ: You must consider whether the "Minimum Order Quantity" of the PCBA components aligns with your project budget and PCBA production volume.

3. Design for Manufacturability (DFM)"Just because it can be designed doesn't mean it can be manufactured."

The "package" of a PCBA component directly impacts the assembly difficulty, yield rate, and cost of the PCBA.

-

PCBA Component Package: Selecting standard SMT packages (like 0402, 0603) is easier to assemble and results in a higher PCBA yield rate than choosing extremely small (like 01005) or difficult (like BGA, QFN) packages.

-

Footprint (Land Pattern) Design: You must ensure the footprint design on the PCB perfectly matches the PCBA component's datasheet specifications. Otherwise, it will lead to massive PCBA soldering defects.

4. Product Lifecycle

-

EOL (End-of-Life) Risk: When selecting PCBA components, you mustabsolutely avoid choosing parts that are "End-of-Life" (EOL) or "Not Recommended for New Designs" (NRND).

-

For example: If you select a chip for your PCBA that will be discontinued in 6 months, it means your product will be forced to undergo a PCBA redesign, prototyping, and re-validation just six months after launch. This will bring you enormous additional costs.

- What are the common cooperation models provided by a PCBA manufacturer, and how should you choose?

- What is a PCB?

RECOMMENDATIONS

_2_cover.png)

_cover.png)