FAQ

What is SMT? How do SMT work on my PCBA?

What is SMT? How do SMT work on my PCBA?

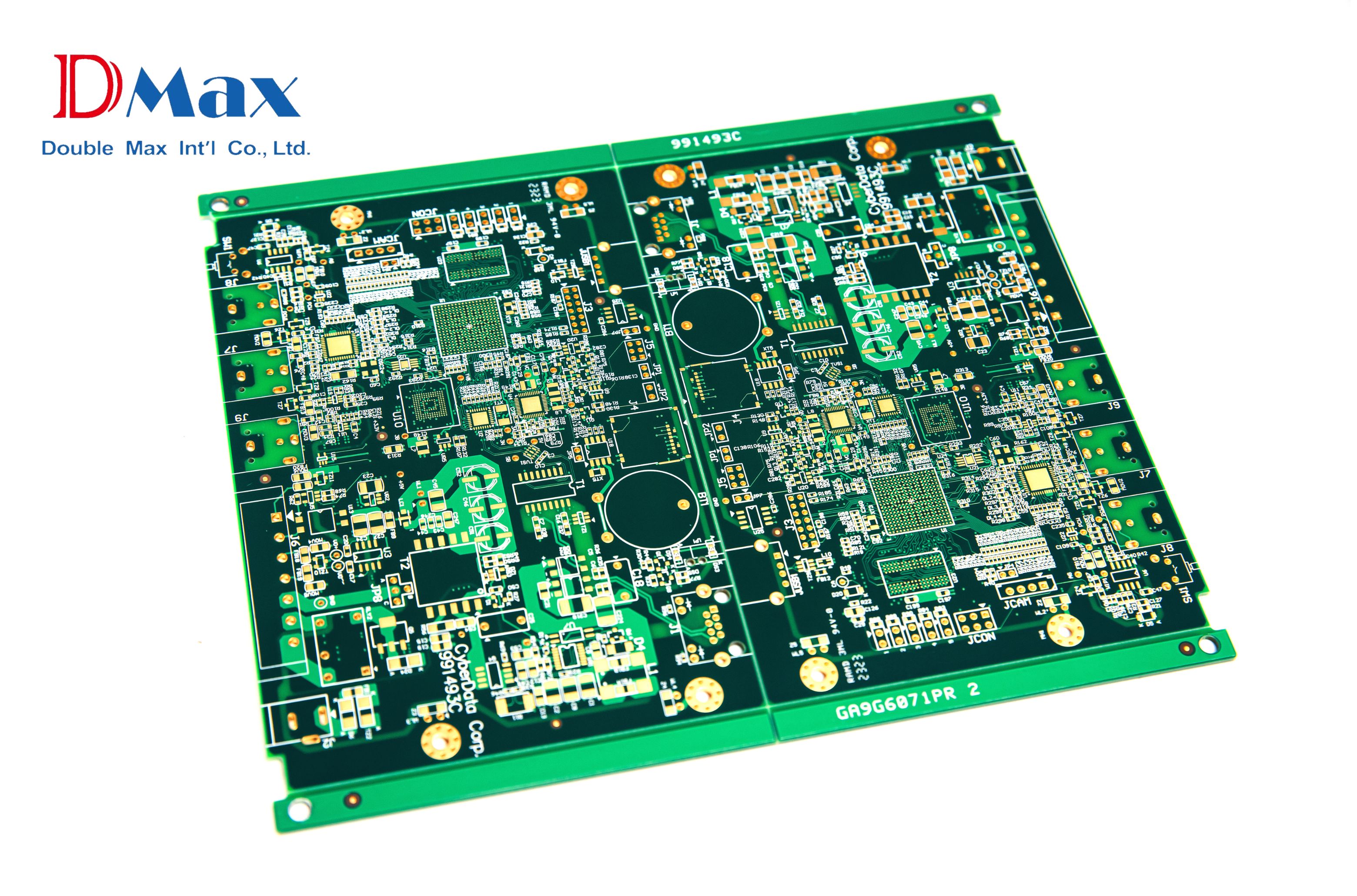

SMT stands for Surface-Mount Technology. It is the absolute mainstream of modern electronics assembly. SMT is a revolutionary, high-precision automated process with a core concept of "placing" and "soldering" electronic components onto the surface of a PCB (bare board).

This is completely different from the traditional DIP (Dual In-line Package) technology, which involves "inserting" component leads through holes in the PCB. Adopting SMT's soldering technology allows PCBAs to become lighter, thinner, shorter, and smaller, further enabling all kinds of modern products to achieve maximum functionality in the minimum amount of space.

The Key Difference Between SMT and DIP

To understand SMT, one must first understand the traditional technology it replaced:

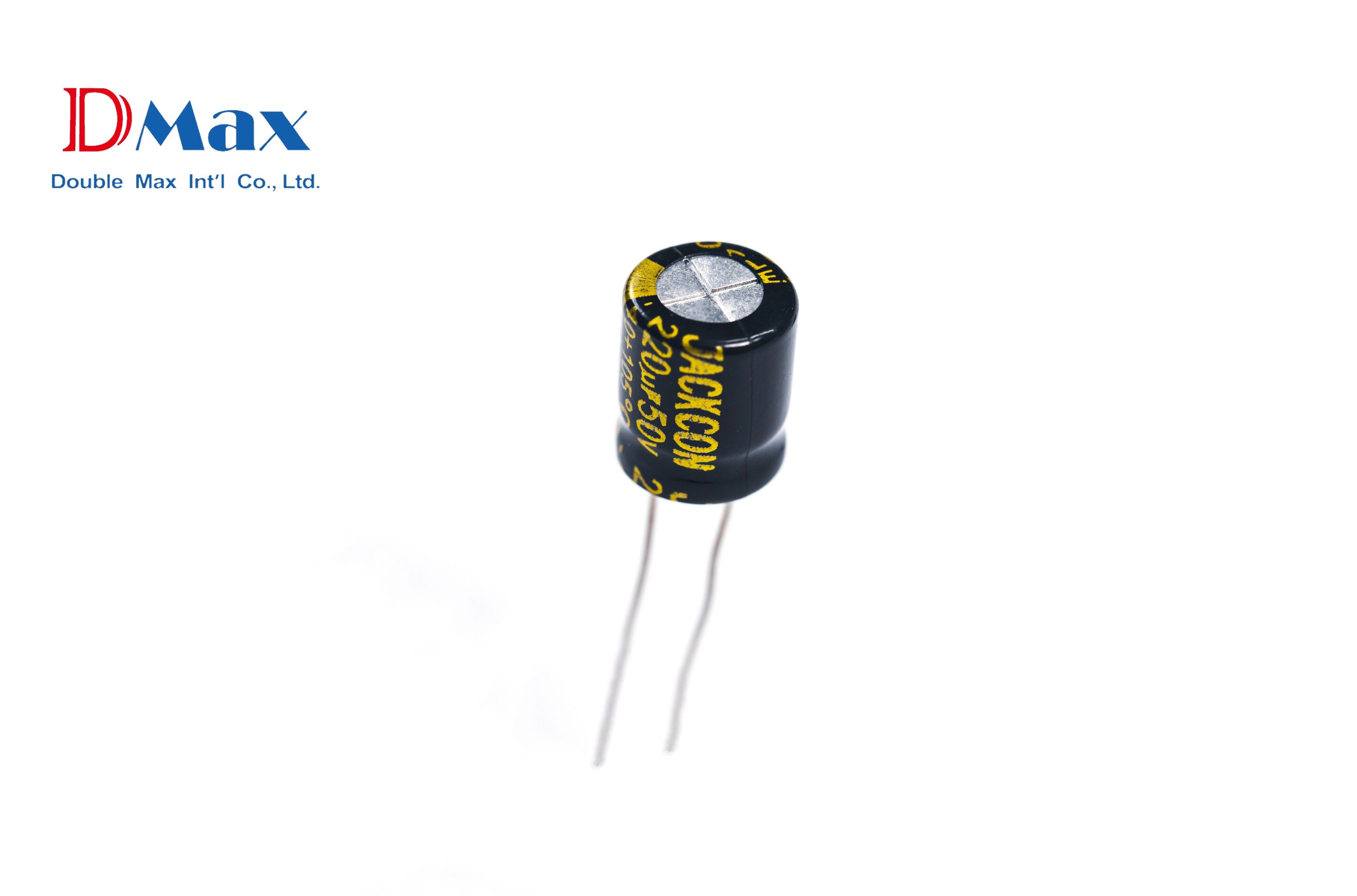

Traditional DIP (Dual In-line Package)

Features: Components have long "legs" (leads).

Process: The component "legs" must be inserted through pre-drilled holes in the PCB and then soldered on the other side of the board.

Disadvantages: Takes up a large amount of space (requires both sides), low routing density, high reliance on manual labor, severe high-frequency signal interference.

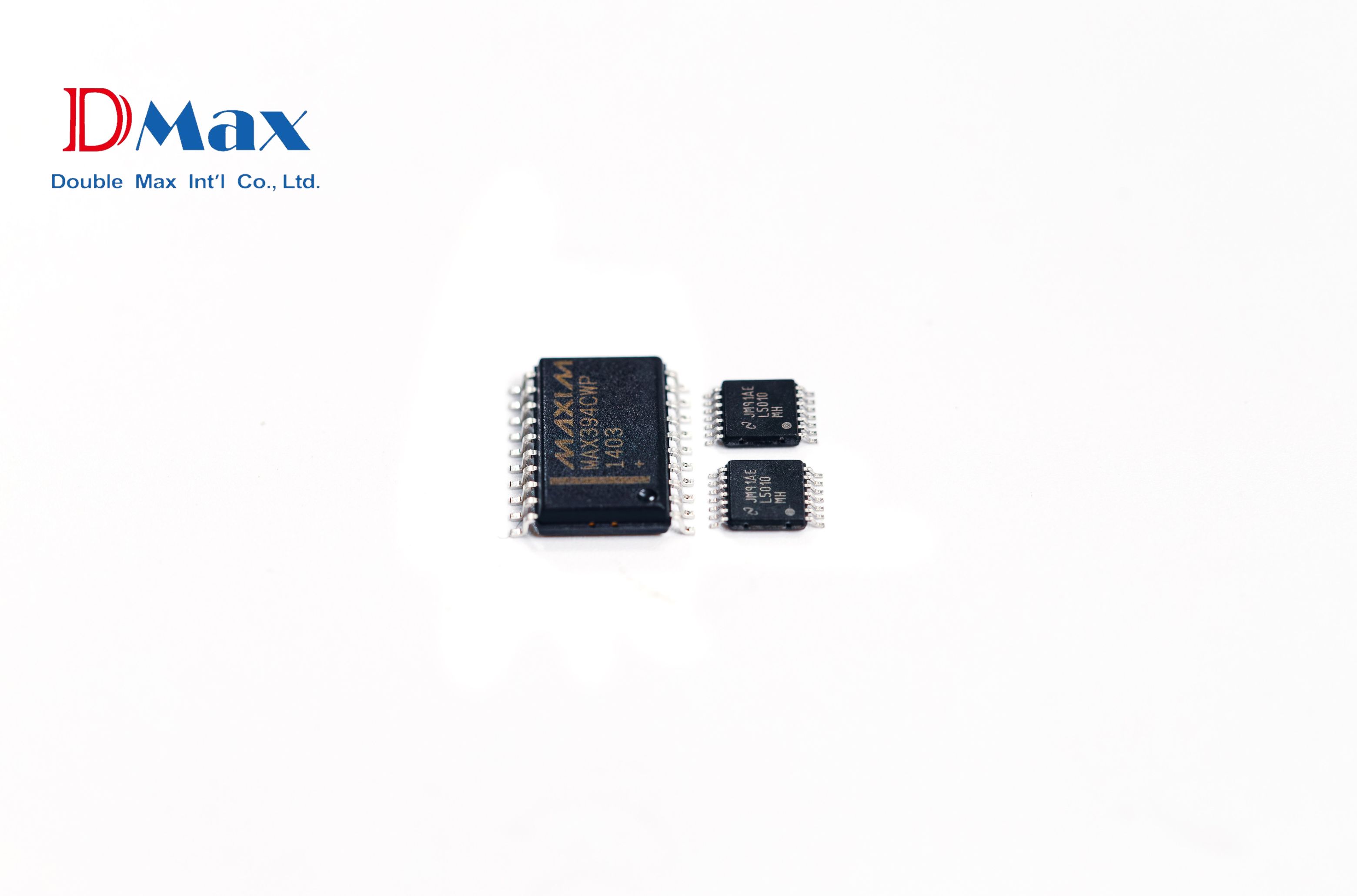

Modern SMT (Surface-Mount Technology)

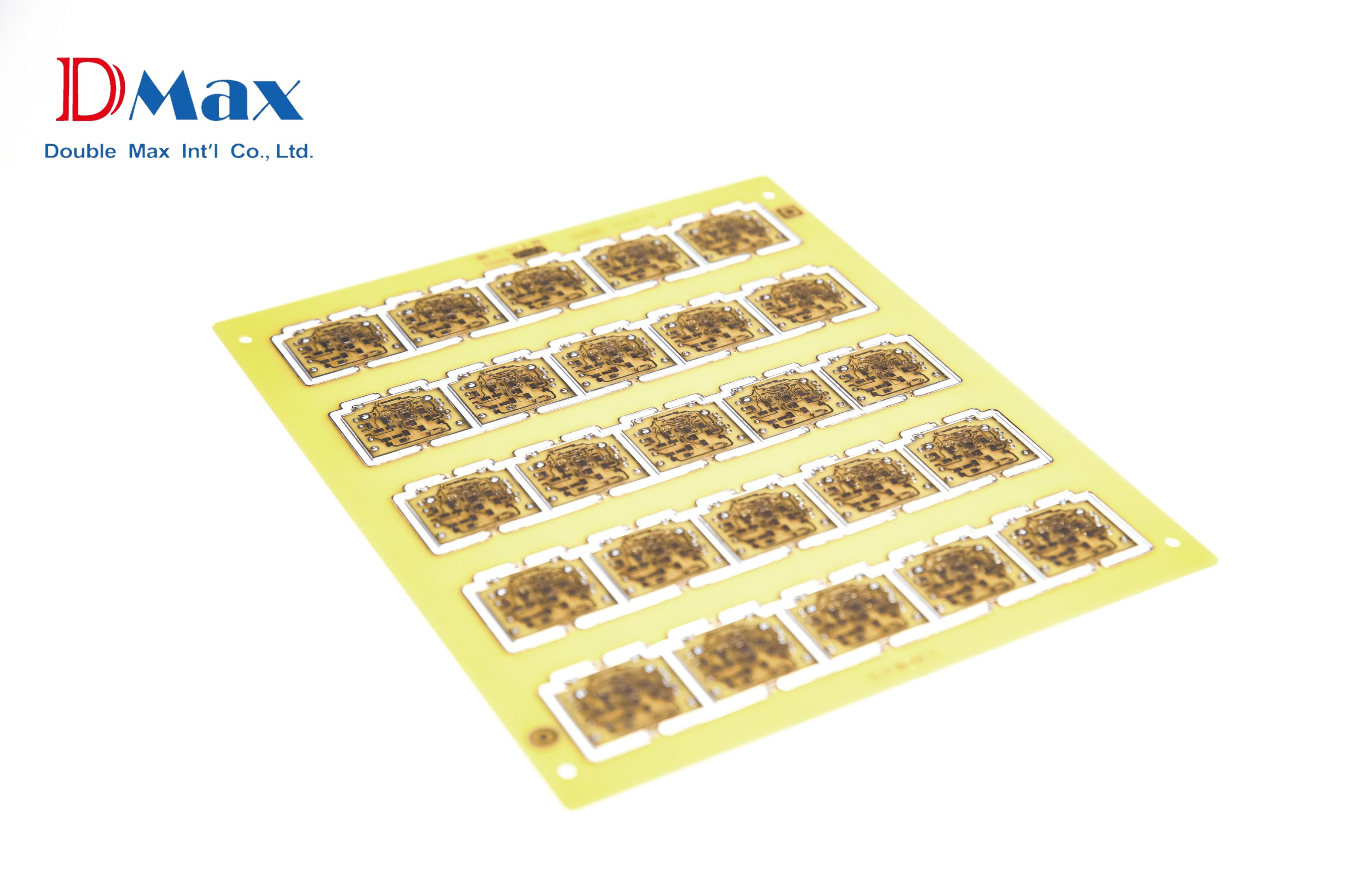

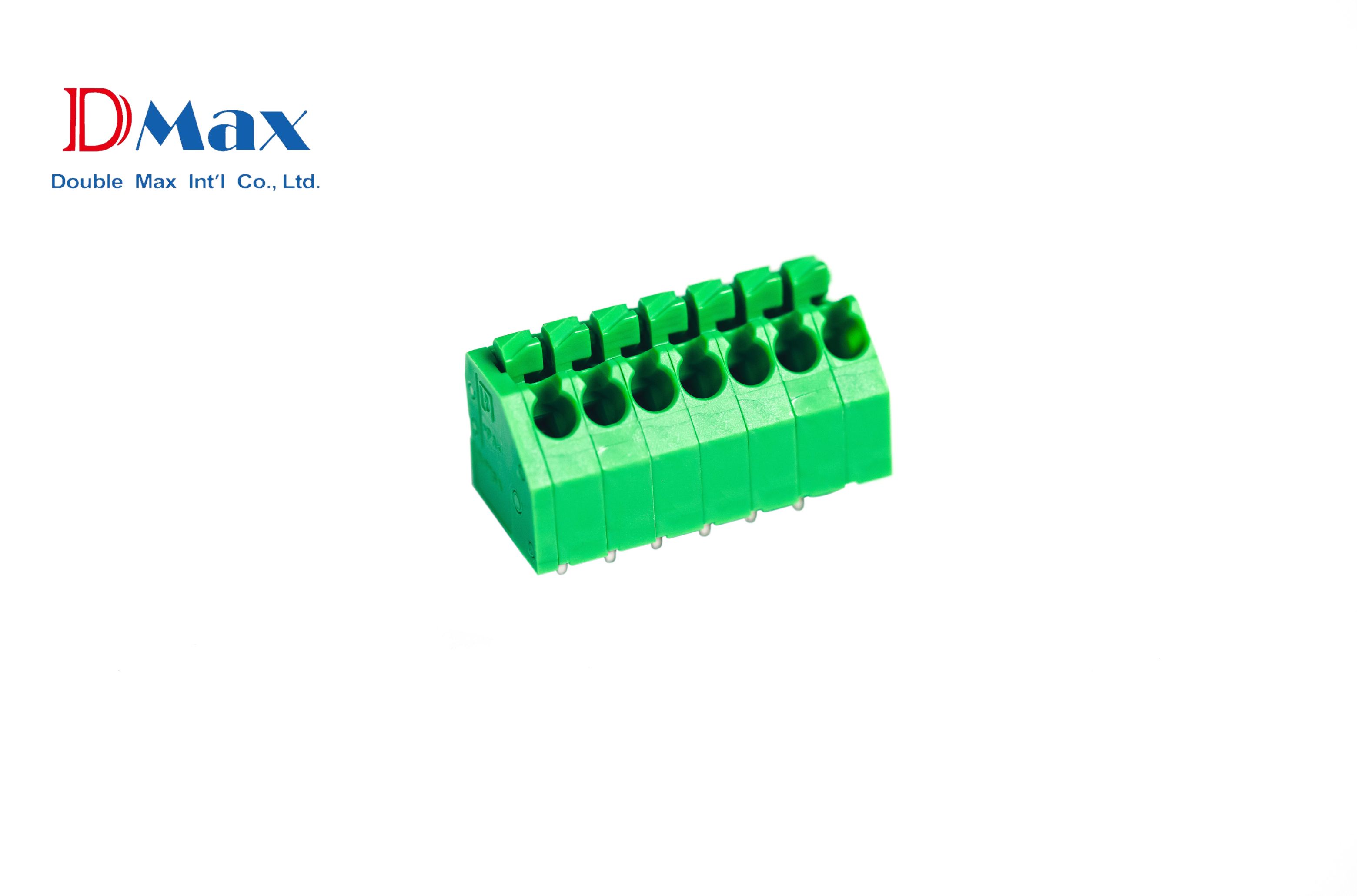

Features: Components (called SMDs / Surface-Mount Devices) are extremely small, have no long leads, and only have flat metal contact points.

Process: Components are placed directly onto solder pads on the same side of the PCB surface and then soldered securely via "reflow."

Advantages: Extreme miniaturization, high density, fully automated, low cost, excellent electrical performance (high-frequency).

The Core Logic of SMT

SMT is a precise assembly line process. Its "logic" is designed to achieve high-quality automated soldering. It mainly includes the following four key steps:

1. Solder Paste Printing

Purpose: To precisely pre-place "solder" onto the PCB's pads.

Method: We use a "Stencil" (a thin steel sheet with apertures) to precisely "scrape-print" "Solder Paste" (a paste made of tiny solder spheres and flux) onto all SMT component pads on the PCB, much like screen-printing a T-shirt.

2. Component Placement

Purpose: To accurately place tiny SMD components onto the solder paste.

Method: This is the job of the "High-Speed SMT Pick-and-Place Machine." This machine reads the PCBA's "Coordinates File," "picks up" components from high-speed "Reels" using a vacuum nozzle, and then "places" them onto the pads at astonishing speeds of "tens of thousands of components per hour."

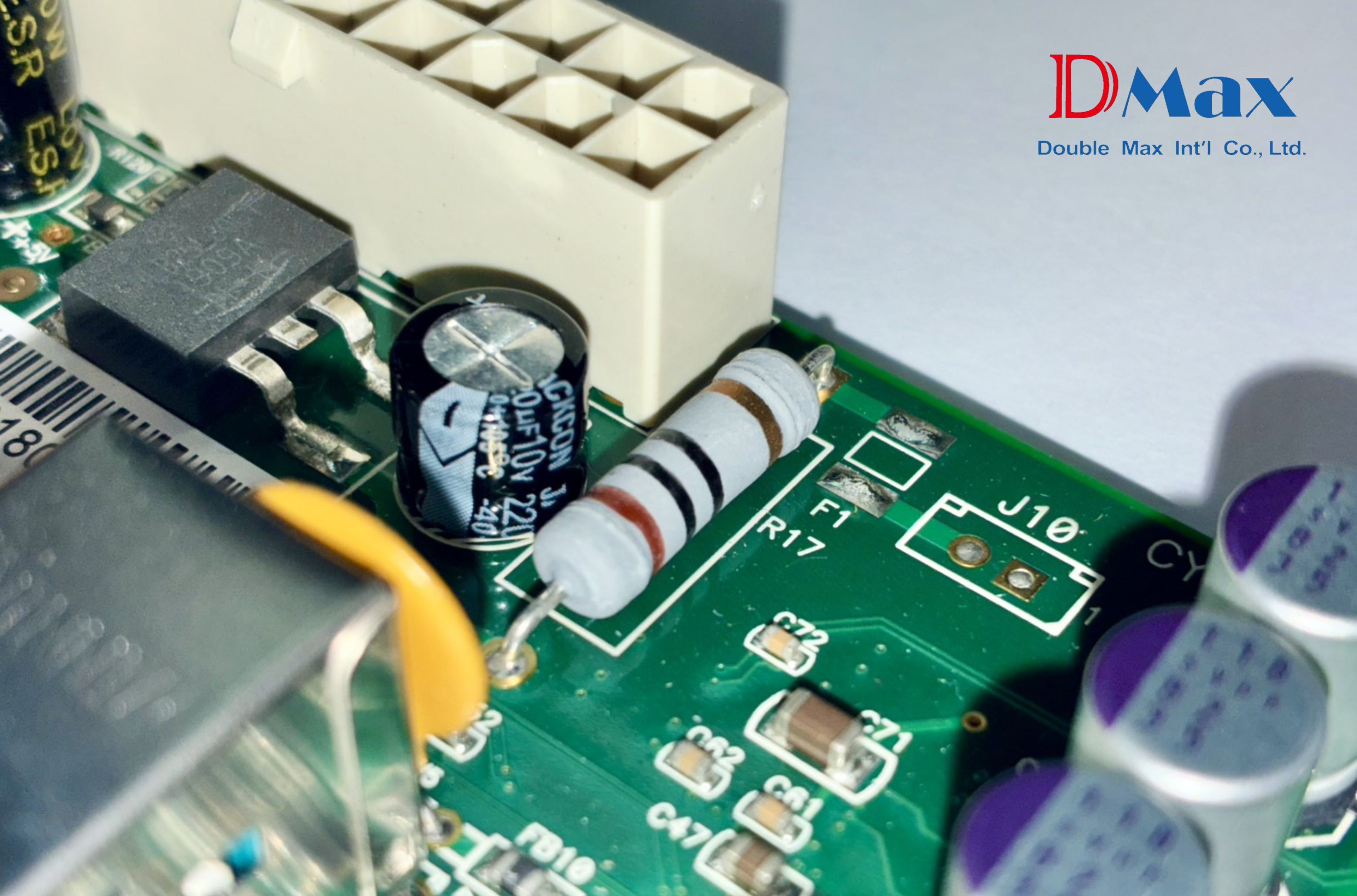

3. Reflow Soldering

Purpose: To melt the solder paste, completing the "soldering" of all components.

Method: The board with its placed components is sent through a long "Reflow Oven" (like a high-precision tunnel oven). The PCBA passes through multiple precisely controlled temperature zones (preheat, soak, reflow, cool). When it passes through the hottest "reflow zone," the solder paste instantly melts into a liquid, perfectly "soldering" the component leads to the PCB pads. It forms a solid, permanent joint upon cooling.

4. Automated Optical Inspection (AOI)

Purpose: To 100% inspect the SMT soldering quality.

Method: After cooling, the PCBA is immediately sent to an AOI machine. The AOI uses high-resolution cameras to automatically "photograph" the board and compare it to a "golden standard" image, instantly catching common SMT defects like component shifting, shorts, open circuits, or "tombstoning" (one end of a component lifting).

SMT Applications: Why is SMT Ubiquitous?

SMT is not an "application" itself; it is the "foundation" that makes all modern electronic applications possible. Its advantages make it ubiquitous:

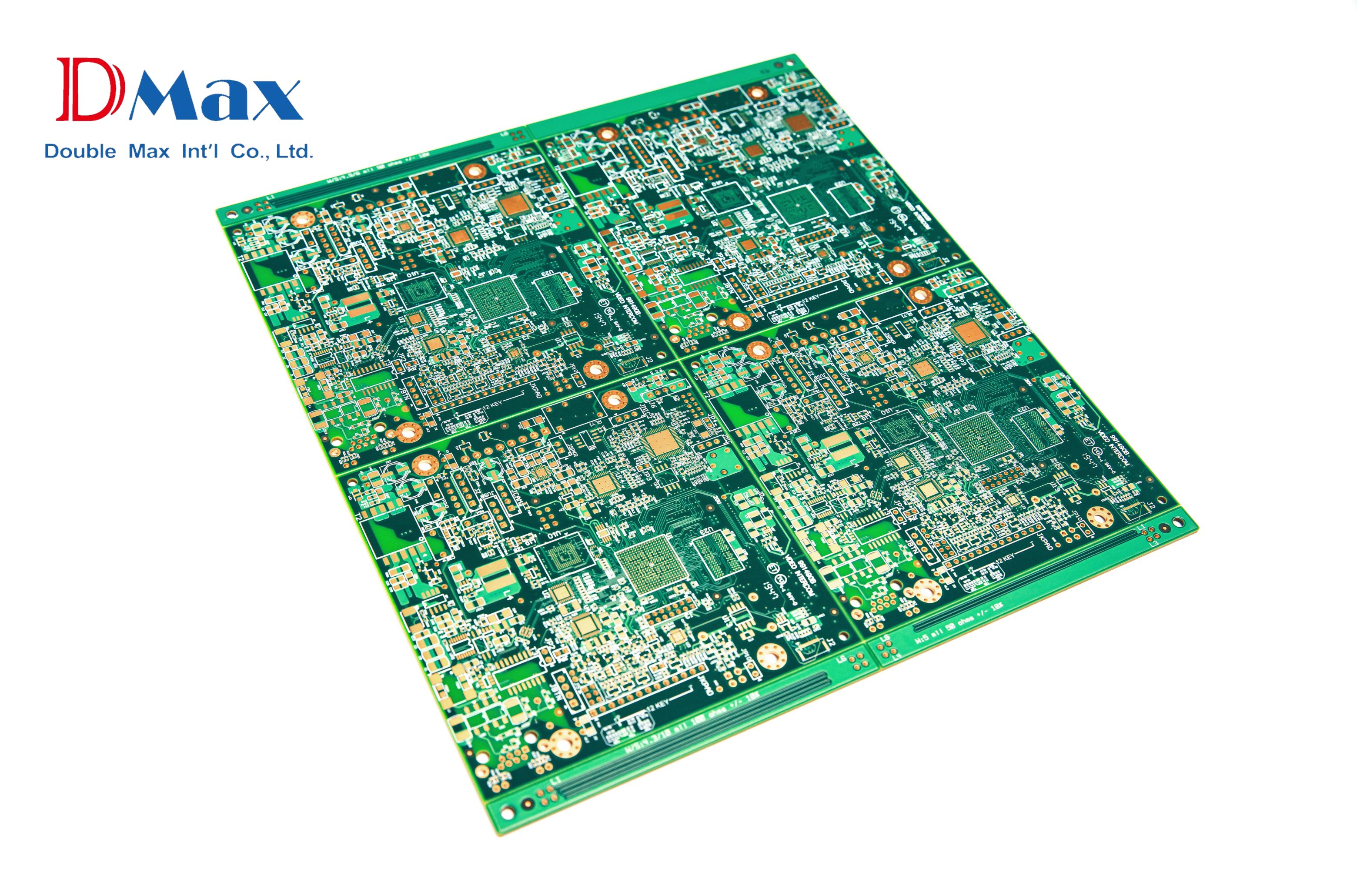

1. Enabling High Density and Miniaturization

Applications: Smartphones, smartwatches, wireless earbuds, micro-medical implants.

Logic: SMT components (SMDs) can be as small as a grain of sand (e.g., 01005 package). Because no "through-holes" are needed, components can be mounted on both sides of the board, allowing for extremely high layout density. Without SMT, modern lightweight and thin electronics would not exist.

2. Enabling High-Frequency Performance

Applications: 5G base stations, Wi-Fi 6 routers, servers, computer motherboards.

Logic: The long leads of traditional DIP components act like antennas, creating noise and signal delays. SMT components have extremely short leads, minimizing the electrical path and signal interference, which is why they are essential for handling high-speed, high-frequency data transmission.

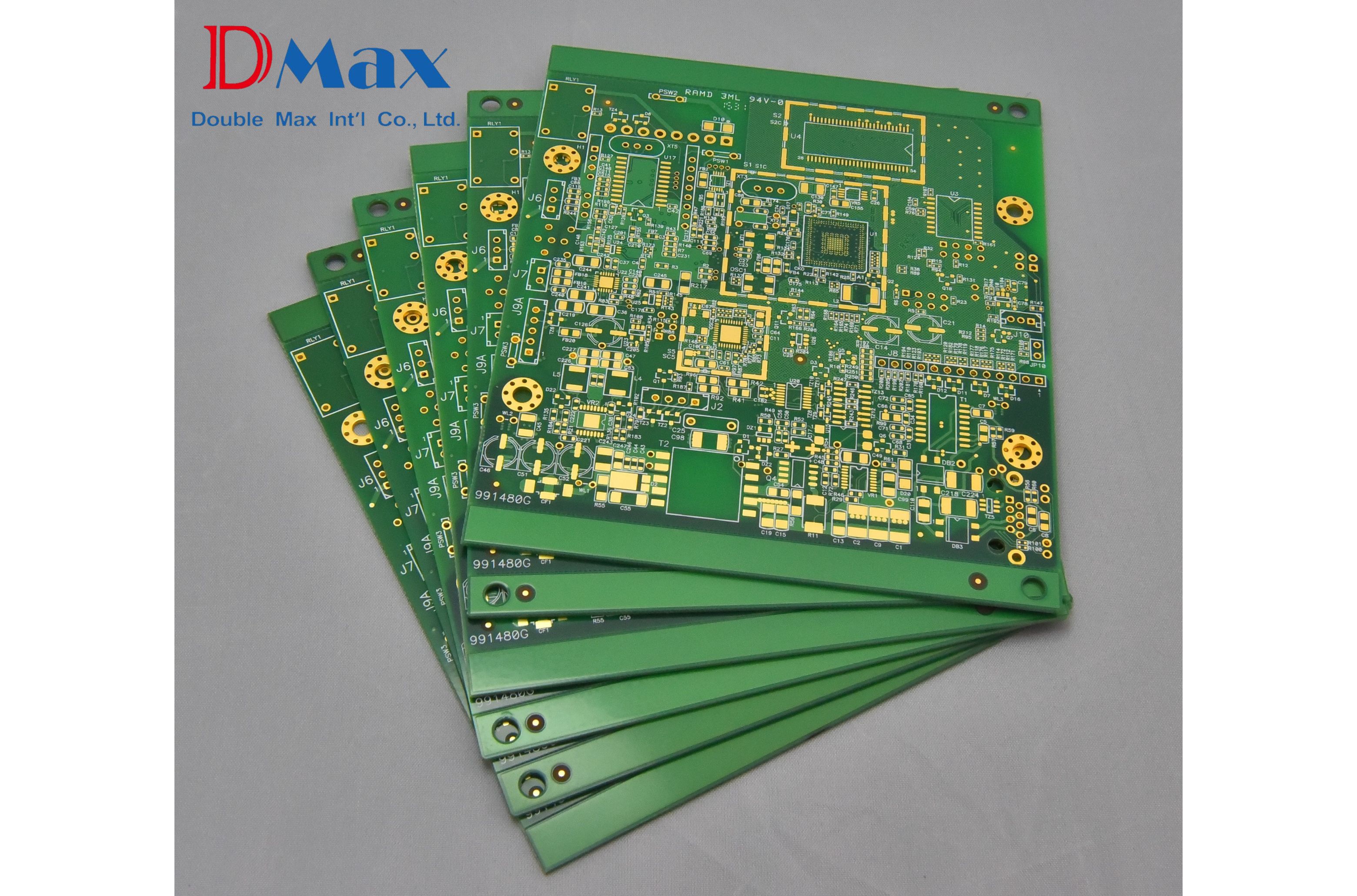

3. Enabling Automated Mass Production and High Reliability

Applications: Automotive electronics, industrial controllers, all products requiring mass production.

Logic: The four main SMT steps are "fully automated." This not only means extremely fast production speeds and low unit costs but, more importantly, it eliminates the errors associated with manual insertion, ensuring that the soldering quality of every single PCBA is highly consistent and reliable.

How does D-MAX execute SMT?

The success or failure of SMT lies not just in the "machines," but in "process control."

D-MAX's core expertise is mastering this complex SMT logic. When you choose D-MAX, you aren't just getting the "action" of placement; you are getting:

1. Pre-Production DFM Engineering Analysis

Before going online, our DFM team has already reviewed your PCBA design, ensuring your PCB footprint design, stencil apertures, and component spacing are 100% suitable for high-yield SMT production.

2. Precise "Stencil" Design

The "amount" of solder paste determines the quality of the solder joint. D-MAX's engineers will precisely design the stencil's aperture thickness and shape based on your component types, laying the foundation for a perfect solder joint from the very first step.

3. Rigorous "Reflow Profile" (Temperature Curve)

This is the "soul" of SMT. Different PCB thicknesses, different components (like BGAs), and different solder pastes all require a customized oven temperature curve. D-MAX uses rigorous temperature profiling tools and extensive process experience to set the perfect reflow profile for your PCBA, ensuring PCBA components are soldered perfectly without being damaged by excessive heat.

SMT is the core process D-MAX uses to manufacture your PCBA. D-MAX not only possesses advanced "High-Speed SMT" equipment but also the professional process "Know-How" to command this equipment. This is the real key to how D-MAX ensures your PCBA's high quality and high yield.

- What is Conformal Coating in PCBA?

- What are the benefits of D-MAX's High-Speed SMT Technology for my PCBA?

RECOMMENDATIONS

_2_cover.png)

_cover.png)