FAQ

What are the benefits of D-MAX's High-Speed SMT Technology for my PCBA?

What are the benefits of

D-MAX's High-Speed SMT Technology for my PCBA?

D-MAX's investment in "High-Speed SMT Technology" for producing PCBAs is not just about "speed."

It is a complete, high-precision, "fully automated" PCBA production line logic. It serves as the "core manufacturing engine" that brings higher quality, lower costs, and a faster time-to-market to your product.

When you choose D-MAX's high-speed SMT production line to manufacture your PCBA, your product will directly gain the following four key advantages:

1. Significantly Shorten Your "Time-to-Market"

The Core of High-Speed SMT: is "High Throughput." Our fully automated Pick-and-Place machines possess the astonishing capability to mount "tens of thousands of components per hour."

Benefits to You:

Rapid Mass Production: For medium to high-volume PCBA orders, we can complete production at extremely high speeds, significantly compressing your manufacturing cycle.

Handling Urgent Orders:

When your product suddenly sells well in the market and requires an urgent reorder, D-MAX's high-speed capacity is your most reliable backing, enabling a swift response to your PCBA demands.

Gaining First-Mover Advantage:

Obtaining your PCBAs faster means your product can be completed and shipped to market sooner, allowing you to seize the market opportunity.

2. Achieve Superior "Quality Consistency" & "High Reliability"

The Process:

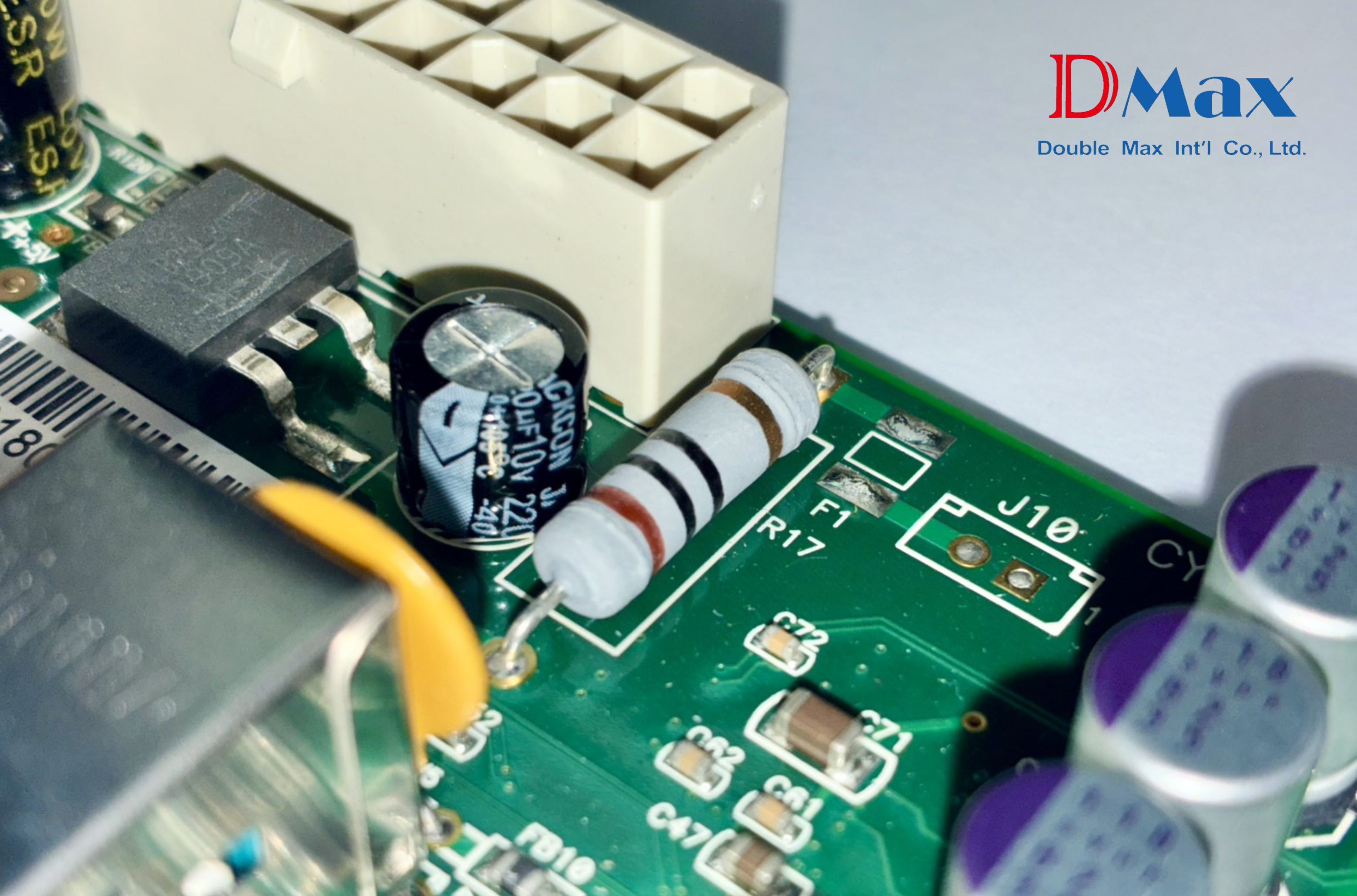

Our high-speed SMT line is "fully automated." Every step, from SPI (Solder Paste Inspection) and component placement to AOI (Automated Optical Inspection), is controlled by precision computers and optical equipment.

Benefits of This:

Elimination of Human Error:

A fully automated production line completely eliminates the fatal mistakes that can occur with traditional manual placement or visual inspection, such as "wrong parts," "missing parts," or "reversed polarity."

High Precision:

The machine's placement accuracy for PCBA components reaches the micrometer (µm) level. Whether it's the 1st PCBA or the 10,000th, the position of every PCBA component and the quality of every solder joint are highly consistent.

Critical Application Assurance:

For high-reliability products where failure is not an option—such as "Medical," "Automotive," or "Industrial Control" applications—D-MAX's automated SMT line is the only choice to guarantee quality.

3. Lower Your "Total Cost of Ownership" (TCO)

The Logic:

The "Economy of Scale" and "High Yield" brought by automation provide you with the following advantages:

Lower Unit Cost:

The faster the PCBA production speed and the higher the degree of automation, the lower the "manufacturing cost (including labor and time) allocated to each individual PCBA."

Less Scrap Loss:

The high precision of SMT, combined with DFM analysis and full AOI inspection, maximizes the PCBA yield rate. This drastically reduces "scrapped boards" and "wasted components" caused by poor soldering.

Stronger Market Competitiveness:

Lower manufacturing costs mean your final product can have a more competitive end-user price.

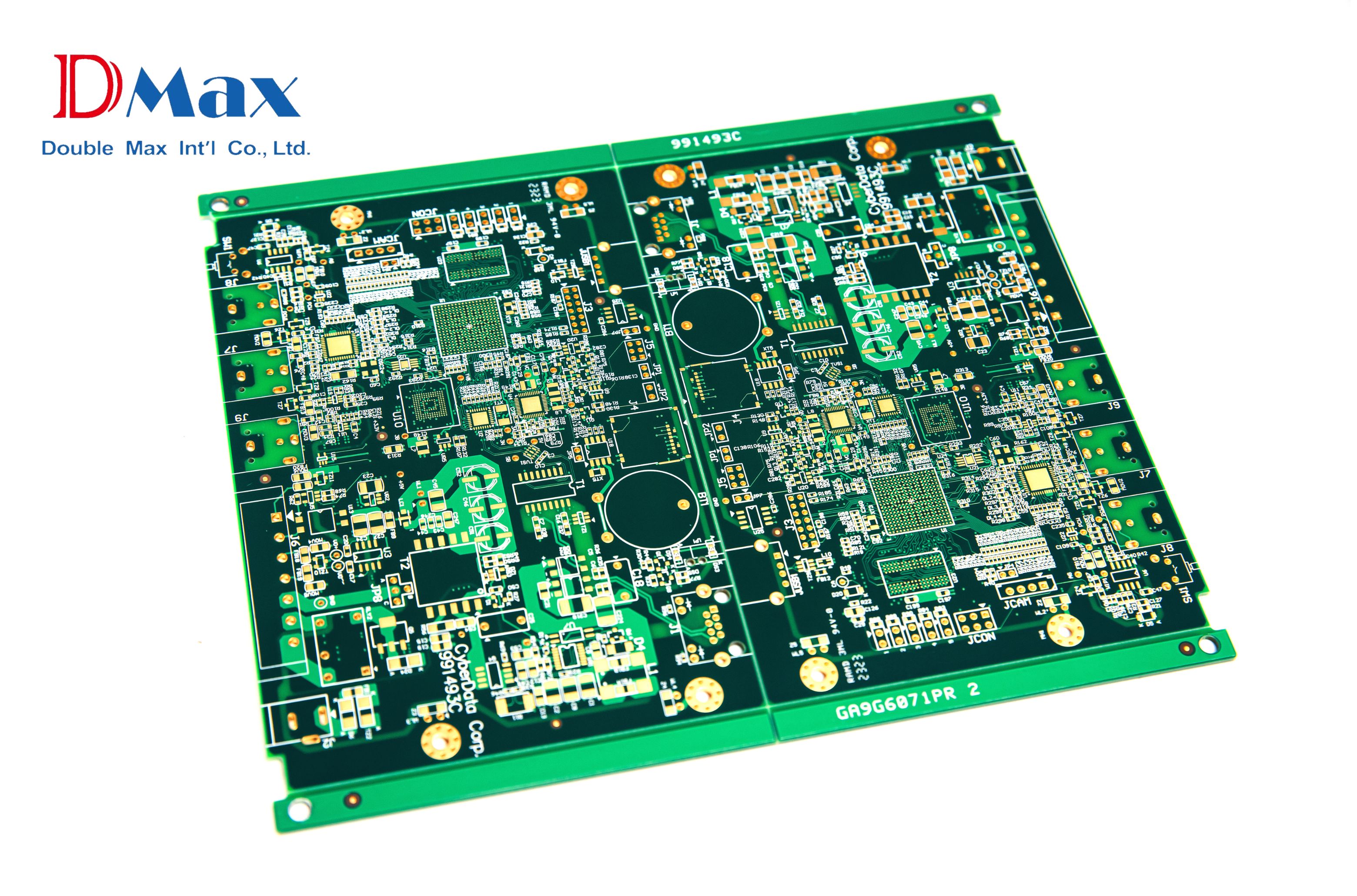

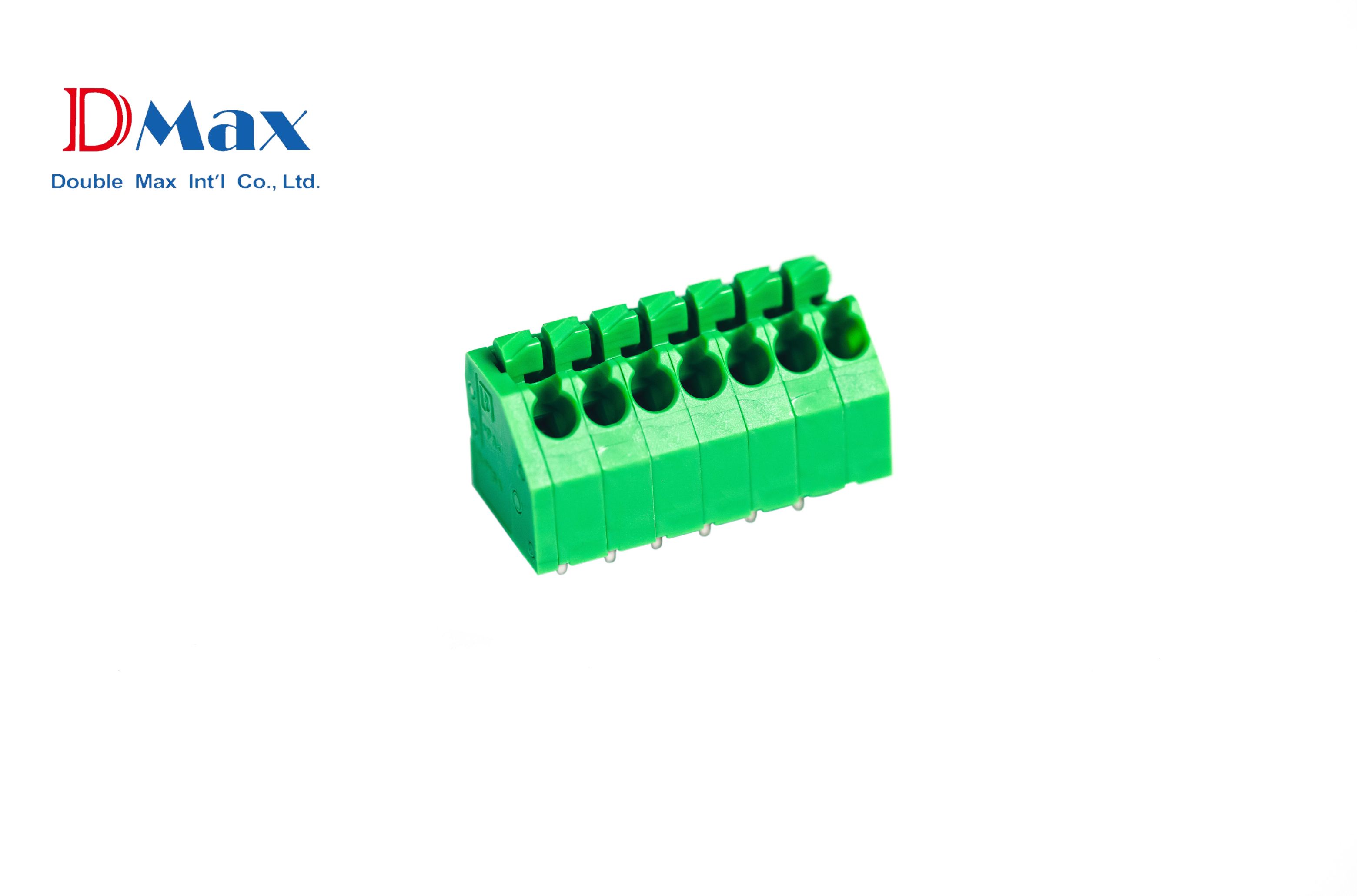

4. Enable "High-Density" & "Complex" Product Designs

The Capability: D-MAX's "High-Speed SMT" equipment is also "High-Precision SMT" equipment. It is designed to handle the complex processes of modern electronic products.

Benefits to You:

Break Design Limitations: Your R&D team can boldly adopt more advanced and miniature components, and D-MAX has the capability to assemble them for you.

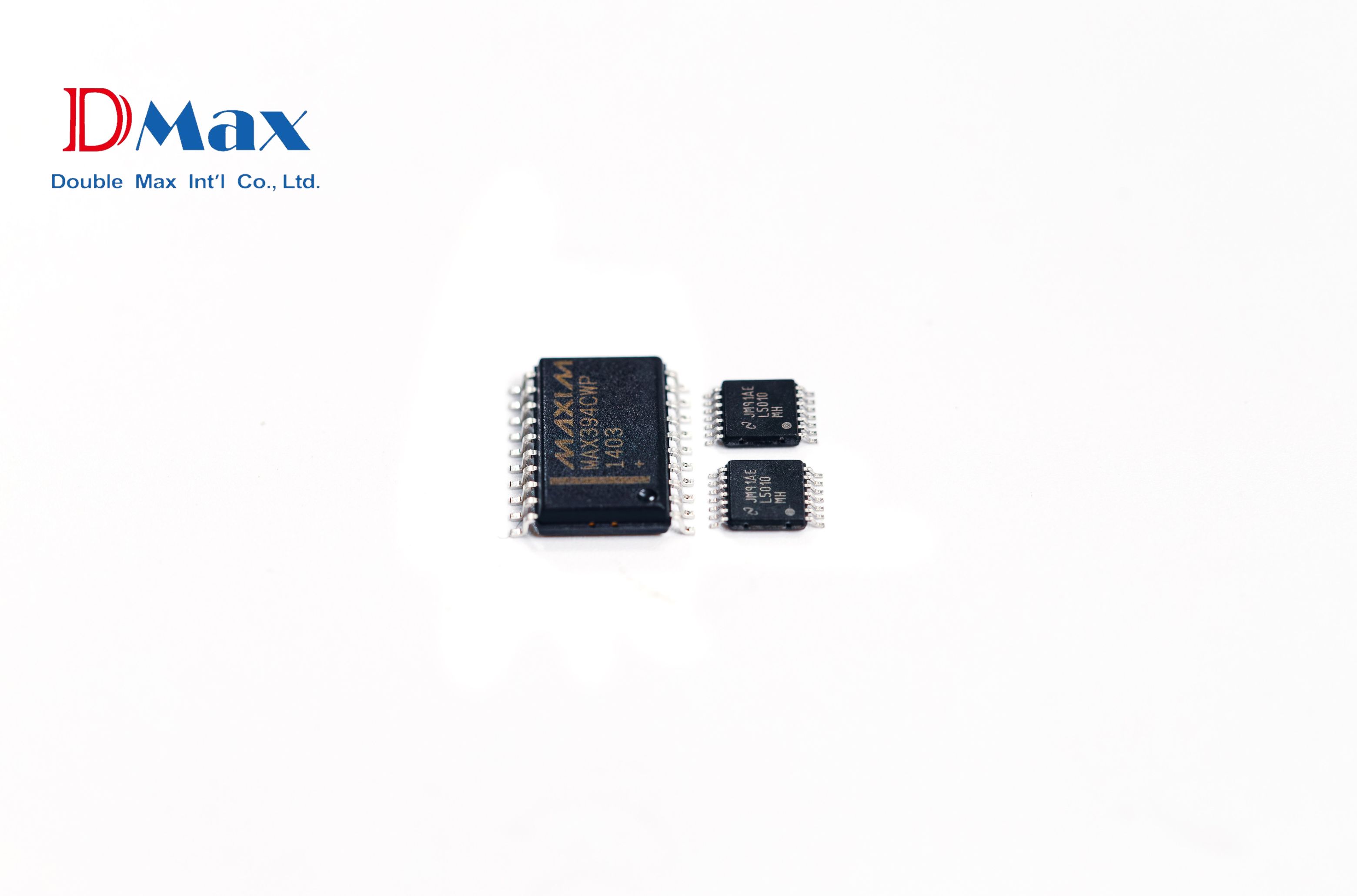

Support for Difficult Components:

We have the ability to stably place tiny 01005 package components (smaller than a grain of sand) and high-difficulty packages like BGA or QFN chips, which have hidden leads.

Achieve Miniaturization:

Our technology supports you in realizing "light, thin, short, and small" product designs, allowing you to pack more functionality into less space.

D-MAX's "High-Speed SMT"

is More Than Just "Machines"

Even the fastest machine will only "produce scrap at high speed" if it lacks "professional process control." Therefore, D-MAX places even greater emphasis on the technical and engineering precision of our professional team, dedicating ourselves to reducing your production costs and waste while providing stable supply and high quality.

The reason D-MAX's high-speed SMT technology can bring you the above benefits is that it is built upon our strong foundation of "Process Engineering":

Pre-Production DFM Review:

Before your files go online, our DFM team has already ensured your design (e.g., footprints, component spacing) is 100% suitable for high-speed automated production.

Precise Process Control:

Our rigorous settings for "stencil apertures," "solder paste selection," and the "Reflow Profile" (temperature curve) are the keys to maximizing the machines' potential.

100% AOI Full Inspection:

Our AOI isn't just used to "catch errors"; it's used to provide "real-time feedback," allowing us to fine-tune SMT parameters and "prevent" errors from occurring at the source.

D-MAX's high-speed SMT technology is the perfect combination of "Speed," "Precision," and "Professional Know-How."

This means we can flexibly and efficiently handle your "low-volume, high-mix" prototypes, and also take on your "medium- to high-volume" mass production orders with the advantages of "high quality and low cost." We are the most powerful and reliable manufacturing partner for realizing your product blueprint.

- What is SMT? How do SMT work on my PCBA?

- What is DIP? How is DIP technology applied in PCBA manufacturing?

RECOMMENDATIONS

_2_cover.png)

_cover.png)