FAQ

What is Conformal Coating in PCBA?

What is Conformal Coating in PCBA?

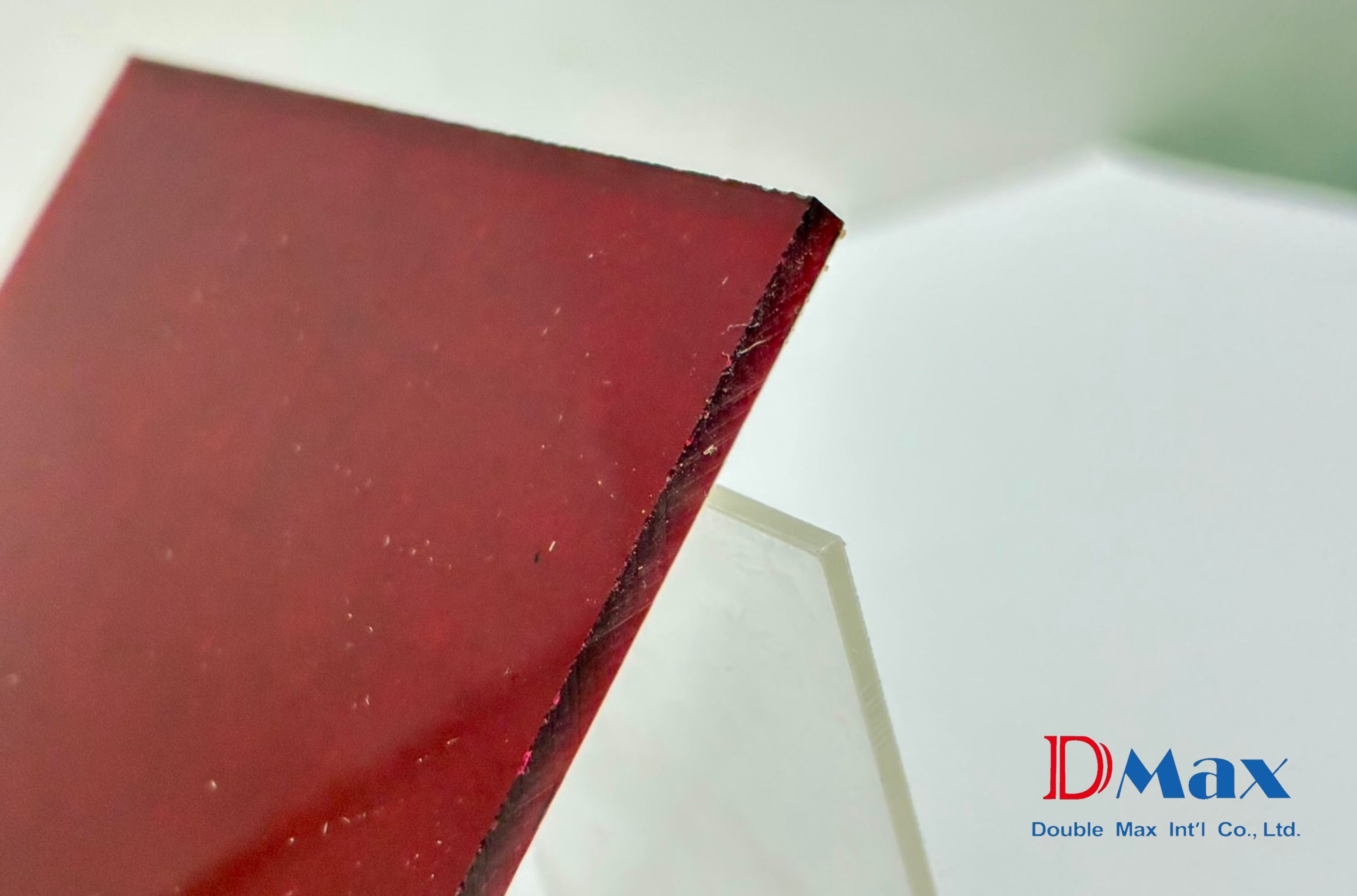

Conformal Coating, is what everyone in the industry commonly refers to as "three-proof paint".

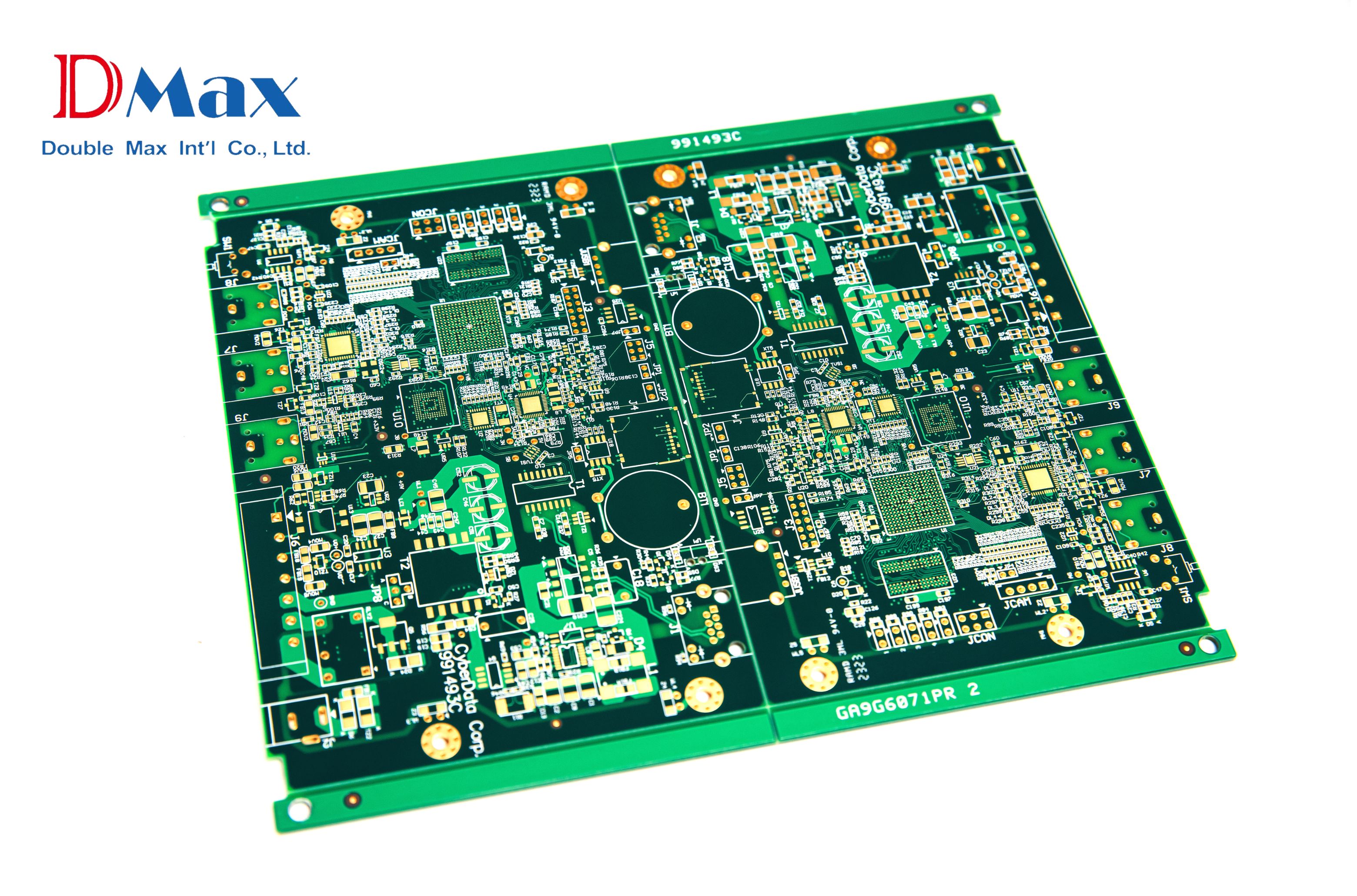

Conformal coating is a critical protective process that is executed only after the PCBA has completed assembly and testing.

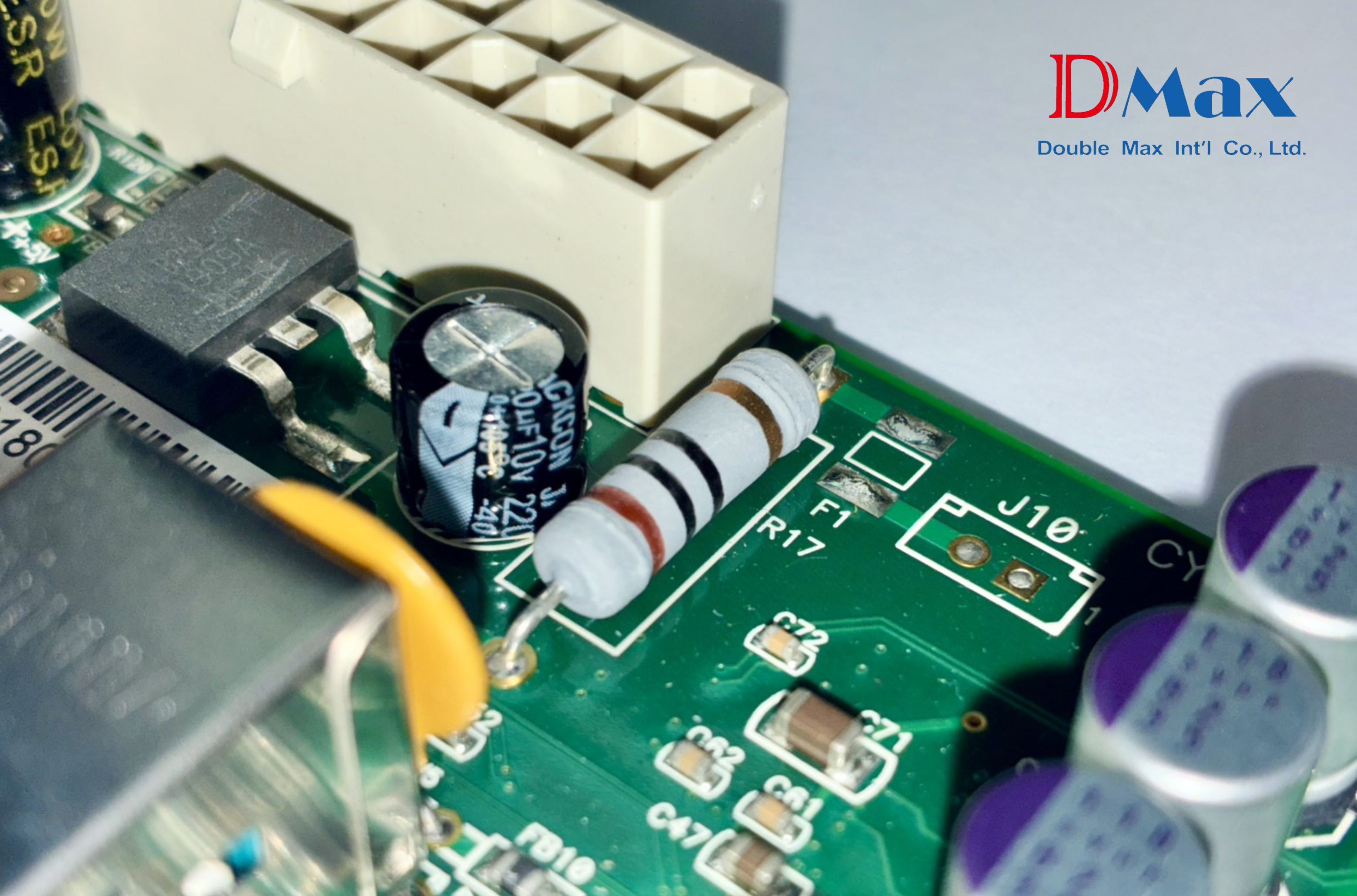

Conformal Coating refers to the application of a thin, transparent, and insulating special polymer film (materials include acrylic, silicone, urethane, etc.) onto the surface of a PCBA. This film "conforms" (hence the name), meaning it can perfectly adhere to the 3D contours of all components and solder joints on the PCBA, forming a transparent, insulating protective "suit" to protect the PCBA from harm.

Why is Conformal Coating so important?

PCBAs must often face many harsh operating environments, including high temperatures, cramped spaces, and long-term operation. Leaving a finished PCBA board with all its components exposed is actually very dangerous and can easily lead to a decline in product quality and stability.

"Three-proof" is a general term; its core purpose is to isolate the board from external hazards. The biggest enemies of a PCBA include:

Moisture / Humidity (Anti-Moisture)

Dust (Anti-Dust)

Salt Spray (Anti-Corrosion)

Without conformal coating, environmental moisture, salt spray, or conductive dust can seep between component leads or onto the PCB's copper traces. This leads to decreased insulation resistance, copper corrosion, current leakage, and ultimately, "intermittent shorts" or even "permanent burnout."

The function of conformal coating is to completely "encapsulate" the entire PCBA, isolating it from the external environment. This can greatly extend the service life of the PCBA in harsh environments and significantly improve the product's long-term reliability.

What industries use Conformal Coating?

However, depending on the product and its requirements, conformal coating is not an absolutely necessary process. It is primarily used in product sectors that involve "harsh operating environments" or "demand extremely high reliability," including:

1. Industrial Automation and Control

Examples: PLCs, frequency inverters, outdoor sensors.

Role of the Coating: To protect the PCBA from the effects of high humidity, high dust, and oil/grease.

2. Automotive Electronics

Examples: ECUs (Engine Control Units), BMS (Battery Management Systems).

Role of the Coating: To protect the PCBA so it can withstand the high temperatures and high humidity of the engine bay, as well as extreme outdoor temperature changes and road salt.

3. Aerospace, Defense & Marine Electronics

Examples: Avionics systems, radar, marine navigation instruments.

Role of the Coating: With coating, the PCBA is better able to operate stably under extreme pressure changes and in harsh environments with high-concentration salt fog corrosion.

4. Outdoor Electronic Equipment

Examples: Outdoor LED billboards, 5G base stations, surveillance cameras.

Role of the Coating: To enable the PCBA to withstand 24/7 exposure to wind, rain, and sun.

5. Medical Devices

Examples: Certain equipment requiring high reliability or resistance to cleaning fluids.

Role of the Coating: It is essential to ensure the machines the PCBA operates have zero-failure reliability, demand high dependability, and enable the electronic equipment to withstand cleaning processes with disinfectant fluids.

How does D-MAX apply Conformal Coating?

Conformal Coating is not "casually spraying from a can" or something as quick and easy as a phone screen protector. It is a highly professional, high-precision "Selective Coating" process. If performed incorrectly, it can lead to disaster.

In D-MAX's professional Conformal Coating process, the most critical step is "Masking":

1. Precise Masking

Areas on the PCBA like "Connectors," "Gold Fingers," "Test Points," and "Screw Holes" must absolutely not be covered by the coating. If the insulating material is sprayed onto the PCBA's connectors, it will cause "poor electrical contact." This PCBA will be permanently disabled and nearly impossible to repair.

Therefore, before applying the coating, D-MAX's professional team uses high-temperature tape, custom-made fixtures, or peelable liquid latex to meticulously protect all "keep-out zones" to avoid compromising PCBA quality.

2. Selective Application

Based on your product's needs, we employ professional application methods (such as precision spraying or dipping) to ensure the coating evenly and completely covers all required PCBA areas.

3. Curing & Inspection

After application, the PCBA enters a specialized oven or passes under UV lamps (depending on the coating type) to "cure."

After curing, D-MAX's QA personnel use a "UV Inspection Lamp" (the coating fluoresces under UV light) to conduct a 100% full inspection, ensuring all areas are evenly coated and all "masked areas" are clean and contamination-free.

Conformal Coating is the final, critical line of defense in D-MAX's Turnkey PCBA service to ensure your high-value product operates reliably for the long term. D-MAX utilizes a rigorous masking and coating process to ensure your PCBA will perform stably to its intended specifications, even in the harshest environments.

RECOMMENDATIONS

_2_cover.png)

_cover.png)