FAQ

What is DFM? What is the importance of DFM for PCBA?

What is DFM?

DFM (Design for Manufacturability) is a proactive and critical engineering analysis process. It is designed to more thoroughly review the feasibility of an engineering plan, preventing the waste of human and financial resources on unproducible designs.

By implementing DFM in the PCBA manufacturing process, D-MAX's professional manufacturing engineers can review your PCBA design and production plan before actual PCBA production and procurement begins. From a "manufacturer's perspective," we identify all potential PCBA production bottlenecks, yield risks, or cost traps.

Why is DFM so important?

In traditional PCBA production models, the R&D department completes a PCBA design and simply "throws the PCBA design files over the wall" to the PCBA production department or a contract manufacturer. The disastrous consequences of this model are frequent: design flaws are only discovered at the last minute on the production line.

For example:

"The chip on your BOM doesn't match the footprint on your PCB!"

"Your component layout is too dense; the DIP components are blocking the SMT components from passing the wave solder!"

"This part you've selected is already EOL (End-of-Life); we can't buy it!"

Once these manufacturing problems are discovered too late, the only solution in most cases is to "start all over." Under these circumstances, you will be forced to modify the design, re-prototype the PCBs, and wait for new PCBA components. This can even impact your product's manufacturing schedule and the entire project timeline, causing R&D costs (including scrapped PCBs and components) to skyrocket.

What key items does a DFM analysis check?

DFM is a comprehensive review covering all aspects of the PCBA. It is mainly divided into three key areas:

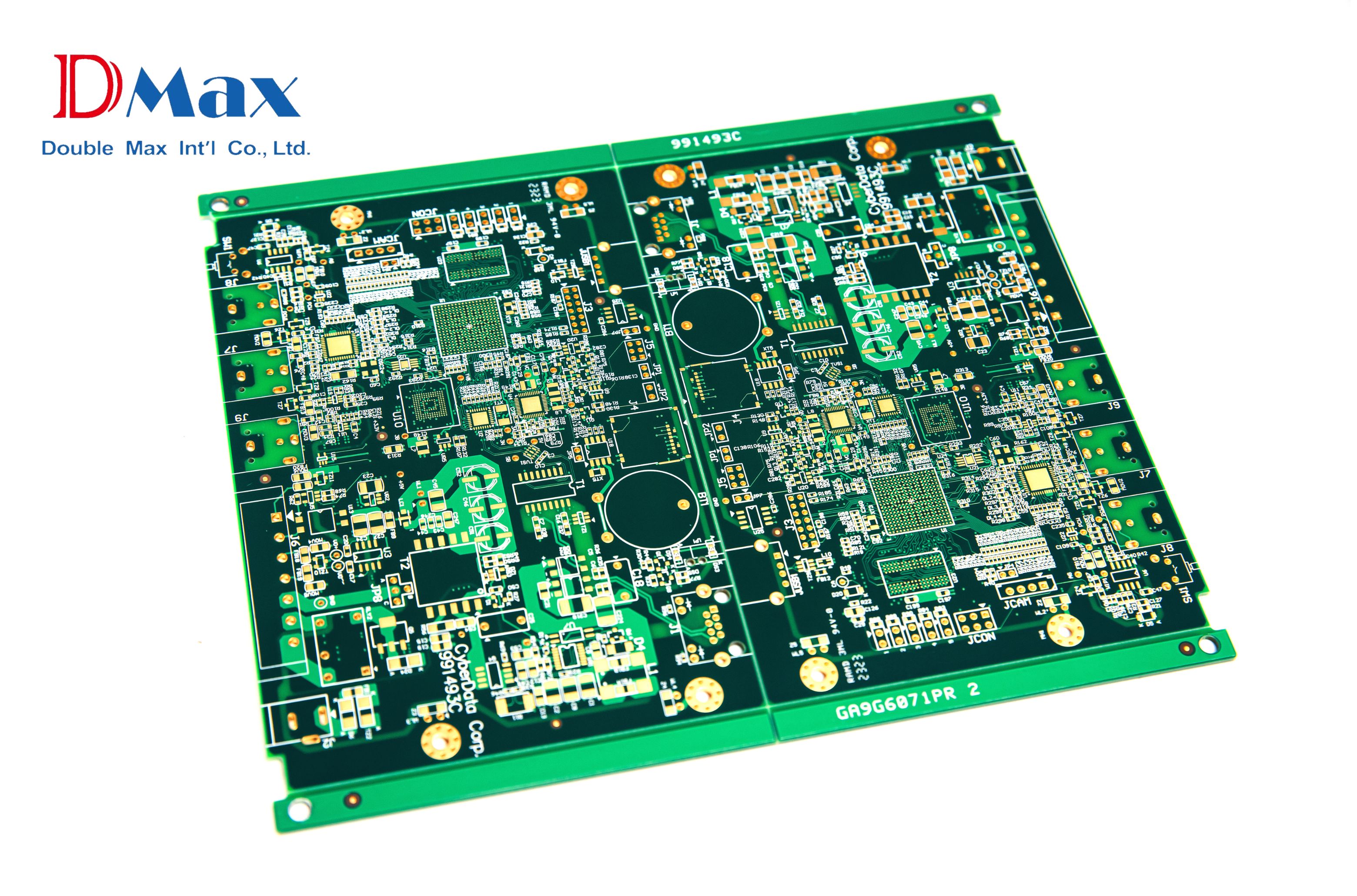

1. DFF (Design for Fabrication) – Analysis for the "Bare PCB" We check your Gerber files to ensure the bare board itself can be manufactured at high quality.

For example: Are the trace-to-trace clearances too narrow? Are drill holes too close to the board edge? Will the copper layout cause the board to warp?

2. DFA (Design for Assembly) – Analysis for the "PCBA Assembly" This is the most critical part. We review your PCB layout and BOM components to ensure they can be assembled and soldered with high efficiency and high yield.

For example:

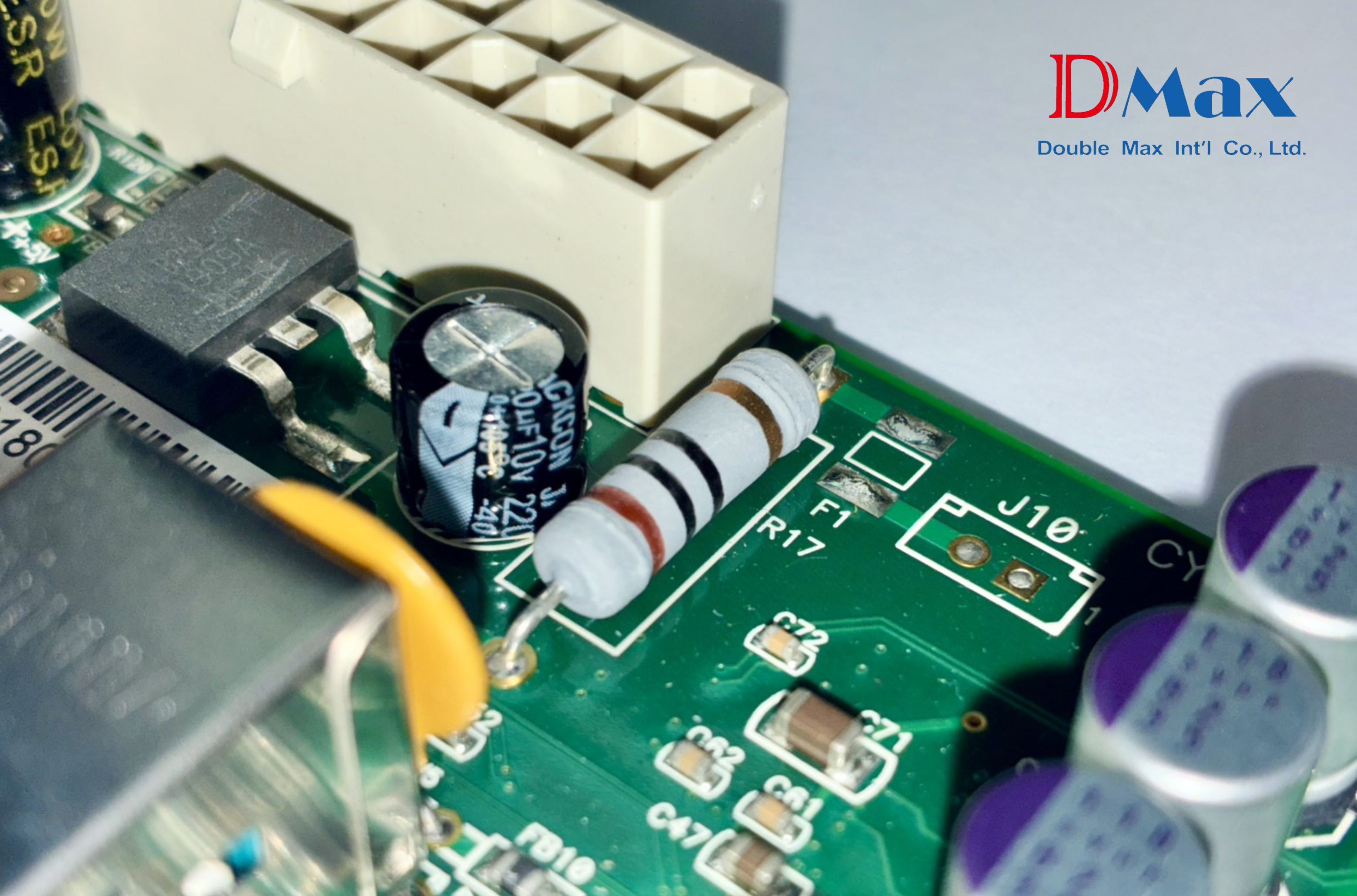

Footprint Design: Does your PCB footprint 100% match the package specified on your BOM?

Component Spacing: Are components too close, preventing SMT placement or causing shorts?

Rework Space: Is there enough space reserved for future rework?

Process Conflicts: Are tall components blocking shorter ones? Will DIP insertion interfere with SMT soldering?

3. DFS (Design for Sourcing) – Analysis for the "Component Supply Chain" This is the unique professional value of D-MAX's Turnkey service. We don't just look at "engineering"; we look at the "supply chain." Our PCBA component procurement team will review your BOM list and proactively flag:

EOL (End-of-Life) Risk: Is this PCBA component about to be discontinued (NRND - Not Recommended for New Designs)?

Lead Time Risk: Is this PCBA component an exclusive part with a 52-week lead time?

Second Source: Does your critical IC have a verified alternate part to mitigate shortage risks?

How does D-MAX implement DFM?

DFM is a "standard built-in procedure" for D-MAX's Turnkey PCBA service.

When we receive your (the customer's) Gerber files and BOM list for a quote, our engineering team will not blindly quote or start production. Instead, we will "proactively" initiate a DFM analysis for you.

We conduct a careful evaluation and ensure the PCBA production plan, PCBA components, and PCBA design are all correct before proceeding to the next step of production. This ensures your product development schedule and project progress are not affected, and that we deliver D-MAX's highest quality PCBA to you on time.

Choosing D-MAX's PCBA Turnkey service isn't just about picking a contract manufacturer; it's about choosing a partner who will help you complete your product manufacturing smoothly and on time. With our many years of professional expertise and technology, we eliminate all potential risks at the very forefront of the project. We ensure from the source that your PCBA production process is smooth and error-free, achieving the goals of high quality, low cost, and on-time market entry.

RECOMMENDATIONS

_2_cover.png)

_cover.png)