FAQ

What services does D-MAX's Turnkey PCBA provide?

What services does D-MAX's Turnkey PCBA provide?

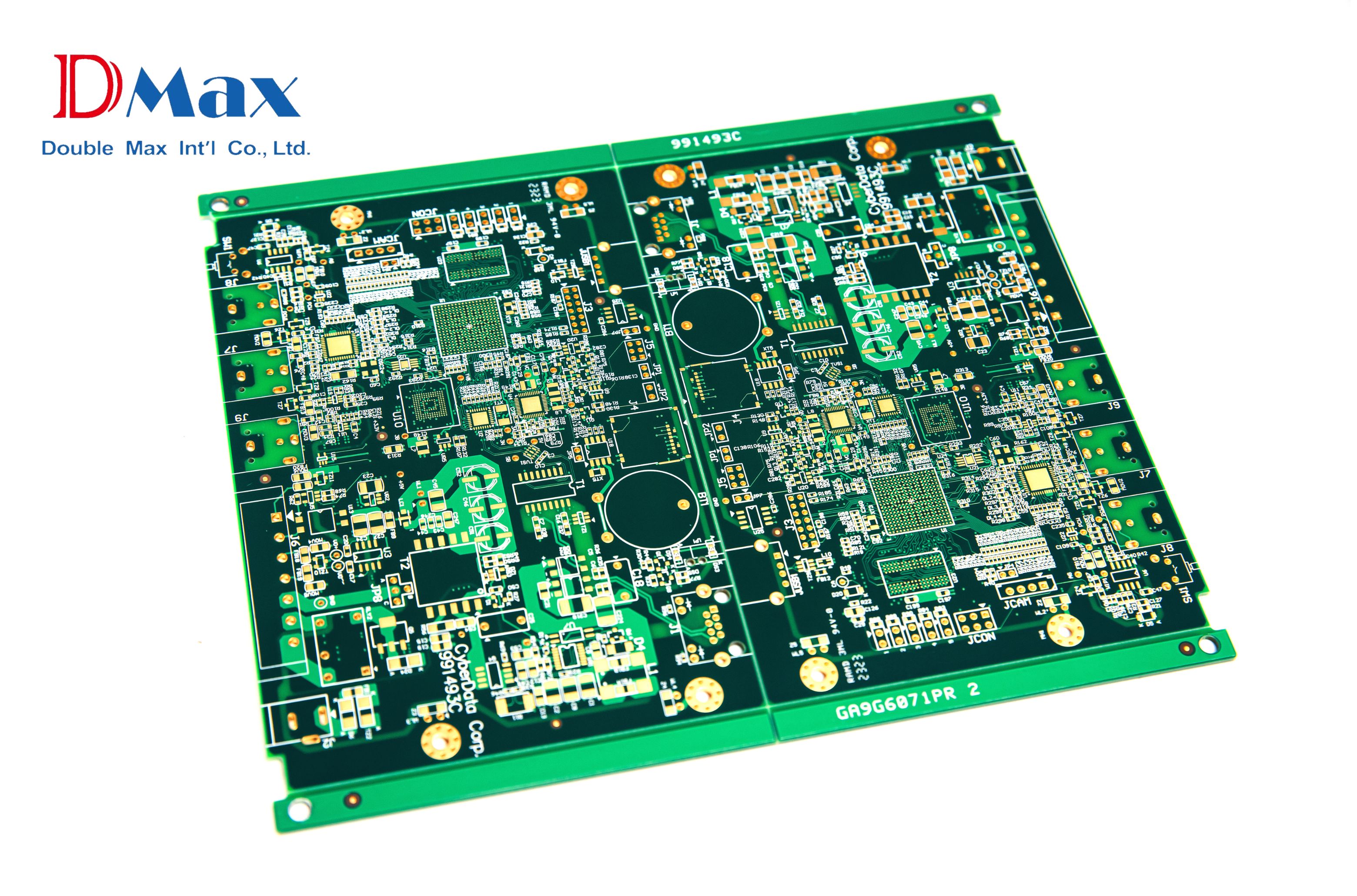

Turnkey PCBA (One-Stop Service) is a comprehensive, high-efficiency PCBA manufacturing solution offered by D-MAX, designed to completely solve the complex PCBA supply chain management pain points you face in traditional PCBA manufacturing processes.

In the traditional PCBA manufacturing process, you would need to source your own bare PCBs, spend a significant amount of time managing and procuring the hundreds of PCBA electronic components on the BOM list, and personally bear the production interruption risks caused by PCBA material delays, shortages, or inconsistent quality. Now, D-MAX's Turnkey PCBA service will solve these troubles and worries for you.

By choosing D-MAX's Turnkey PCBA (One-Stop Service), you only need to provide your design files (Gerber and BOM). D-MAX will act as your Single Point of Contact, managing the entire PCBA production and manufacturing process for you, and delivering a PCBA that perfectly meets your requirements. From "raw materials" to "finished product," every step is managed, allowing you to have peace of mind and focus more on your product's manufacturing and design.

D-MAX's Turnkey service includes the following processes:

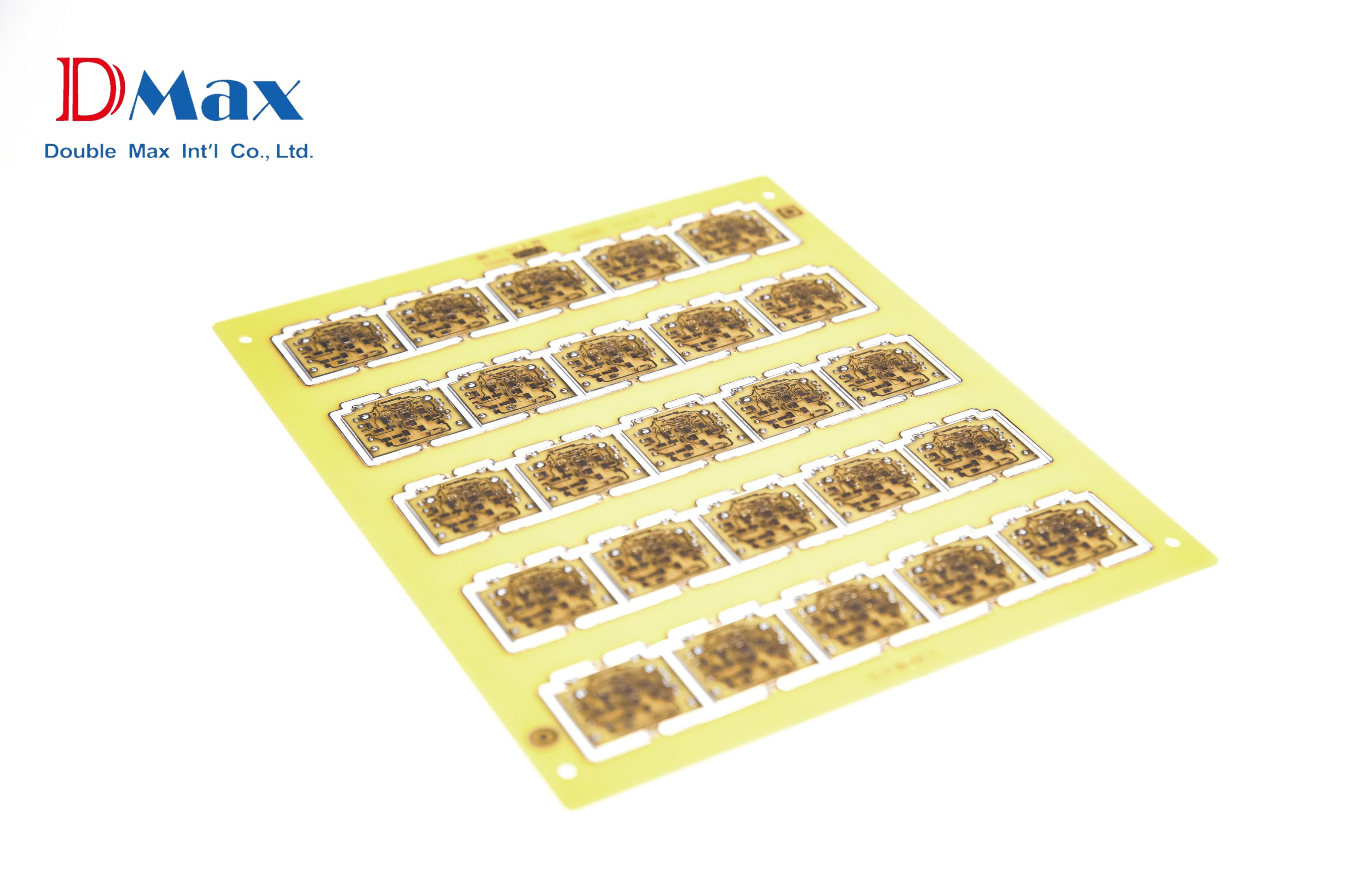

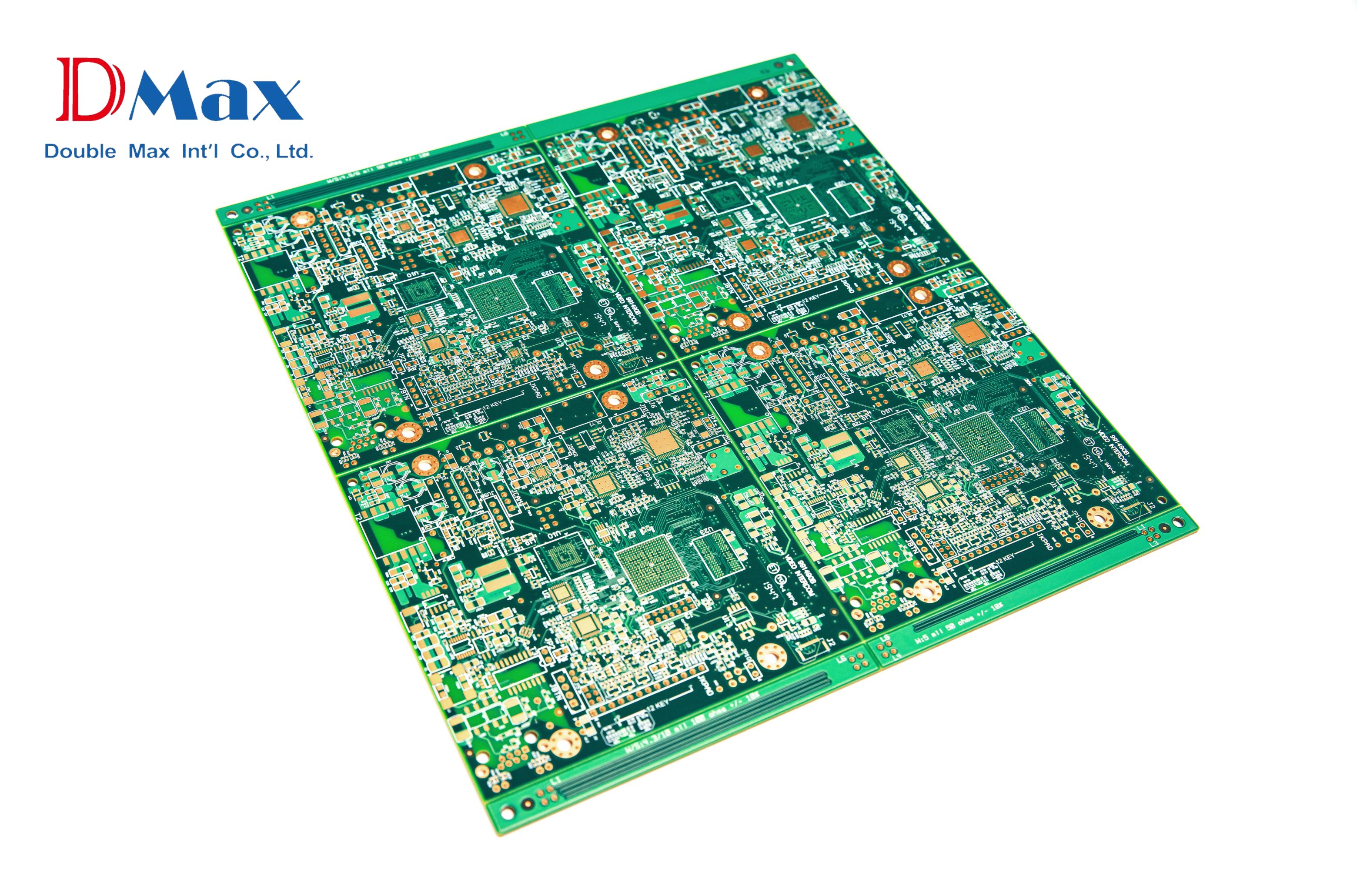

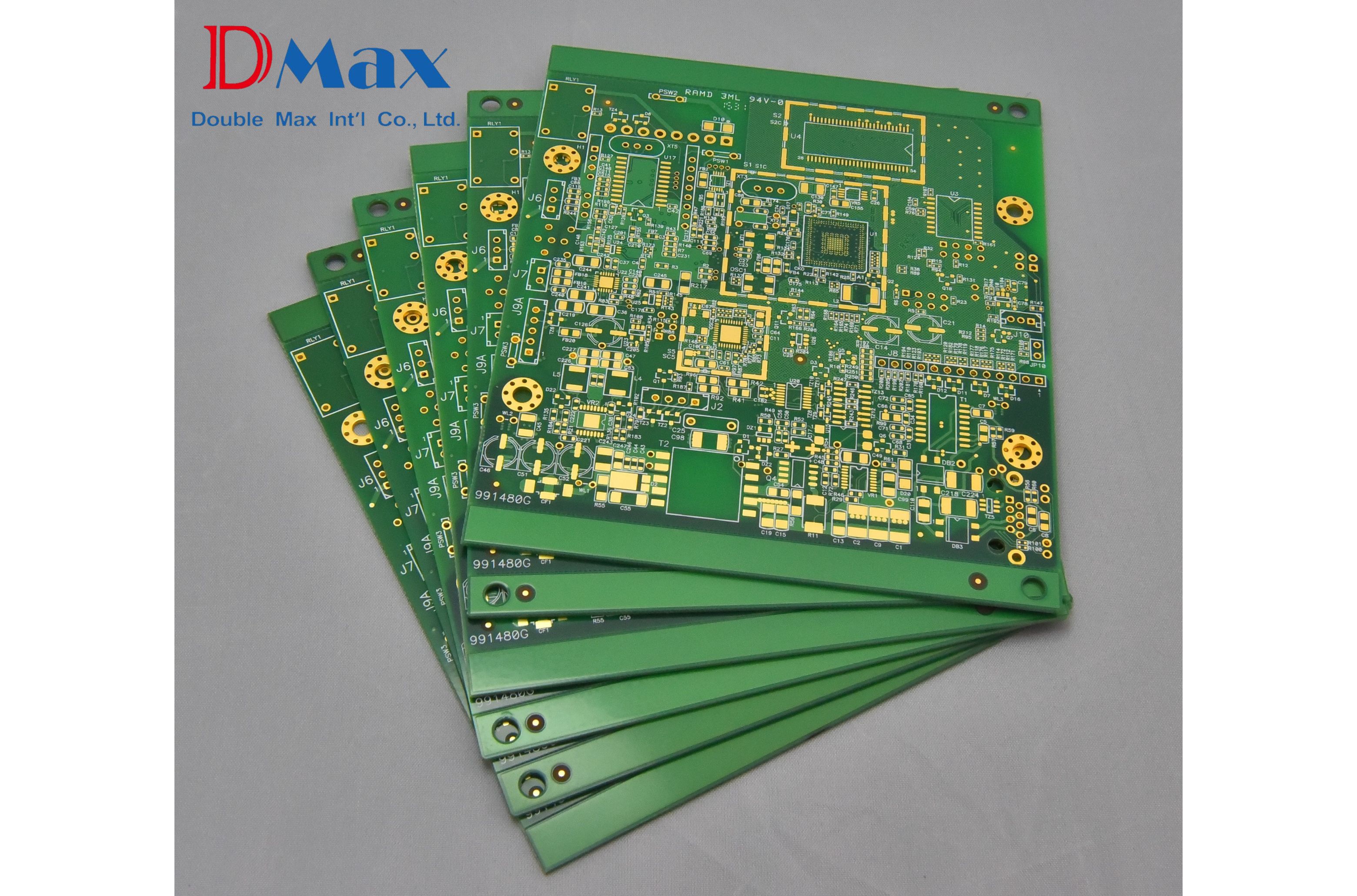

1. PCB Fabrication D-MAX will handle the manufacturing of the bare PCBs and plan a complete, customized manufacturing solution for you.

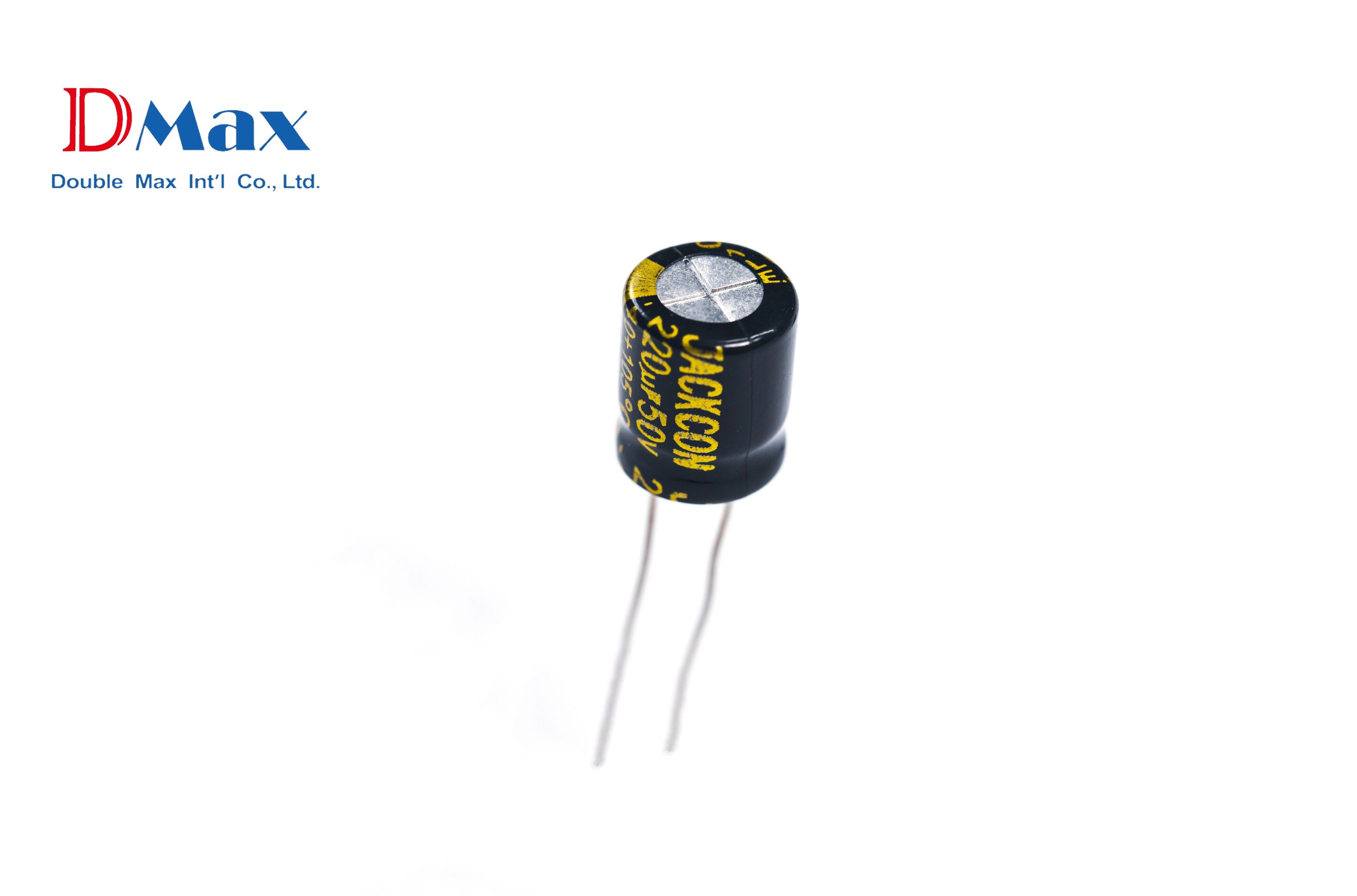

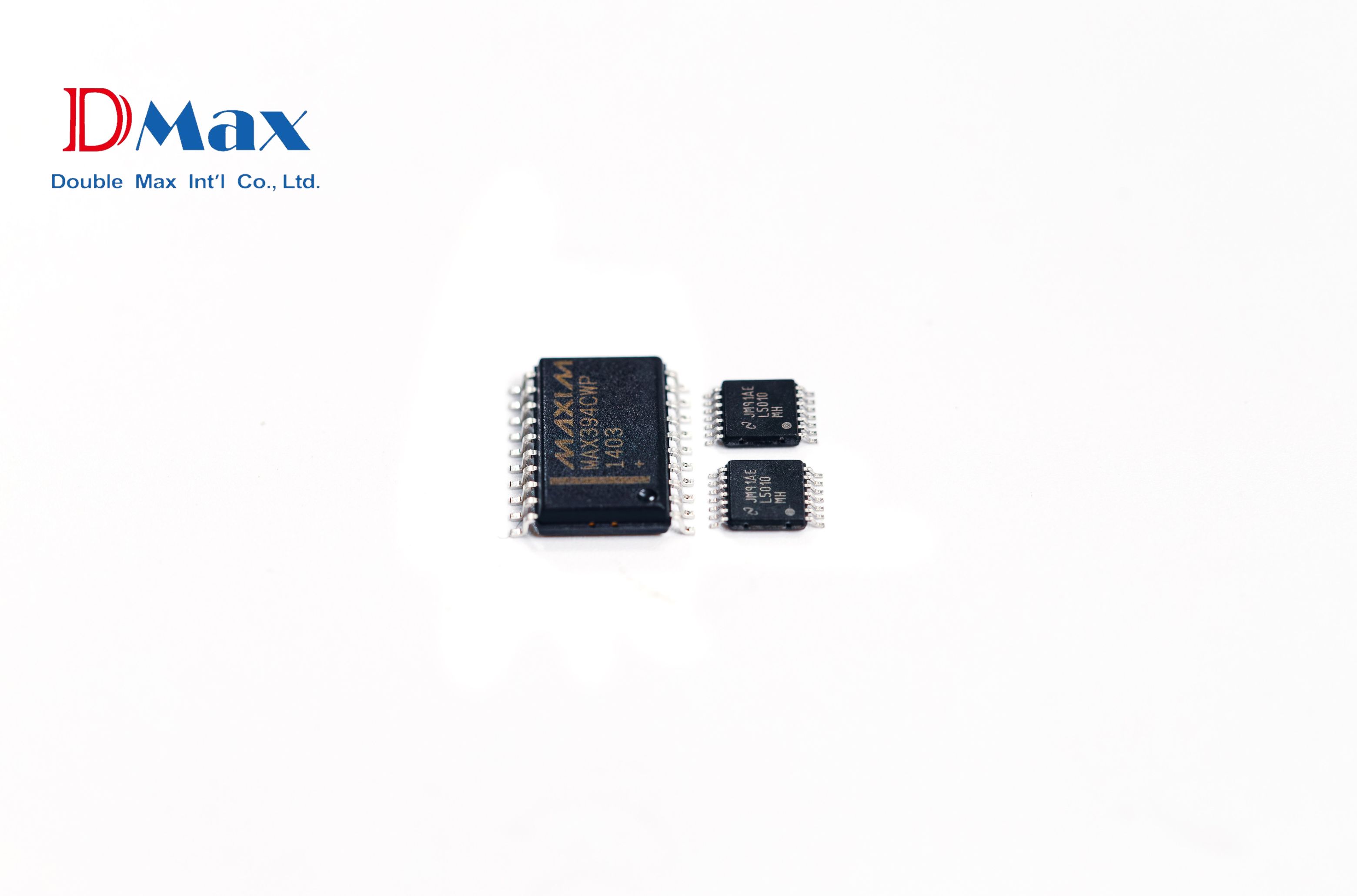

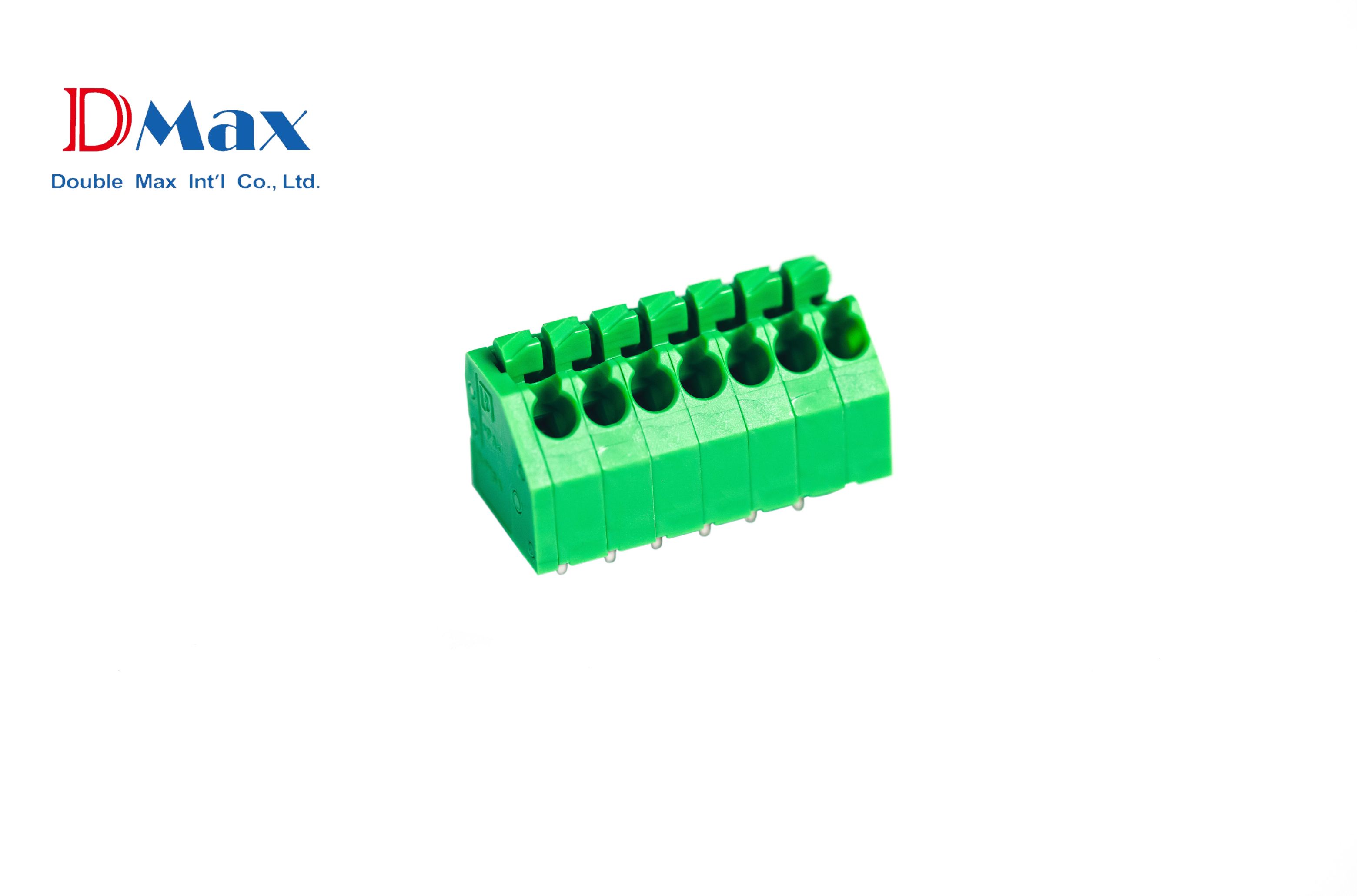

2. Full BOM Sourcing (Electronic Components Procurement) D-MAX utilizes its high-efficiency and reliable procurement capabilities to source all PCBA electronic components on your BOM list, ensuring proper delivery speed and stable production status for all components.

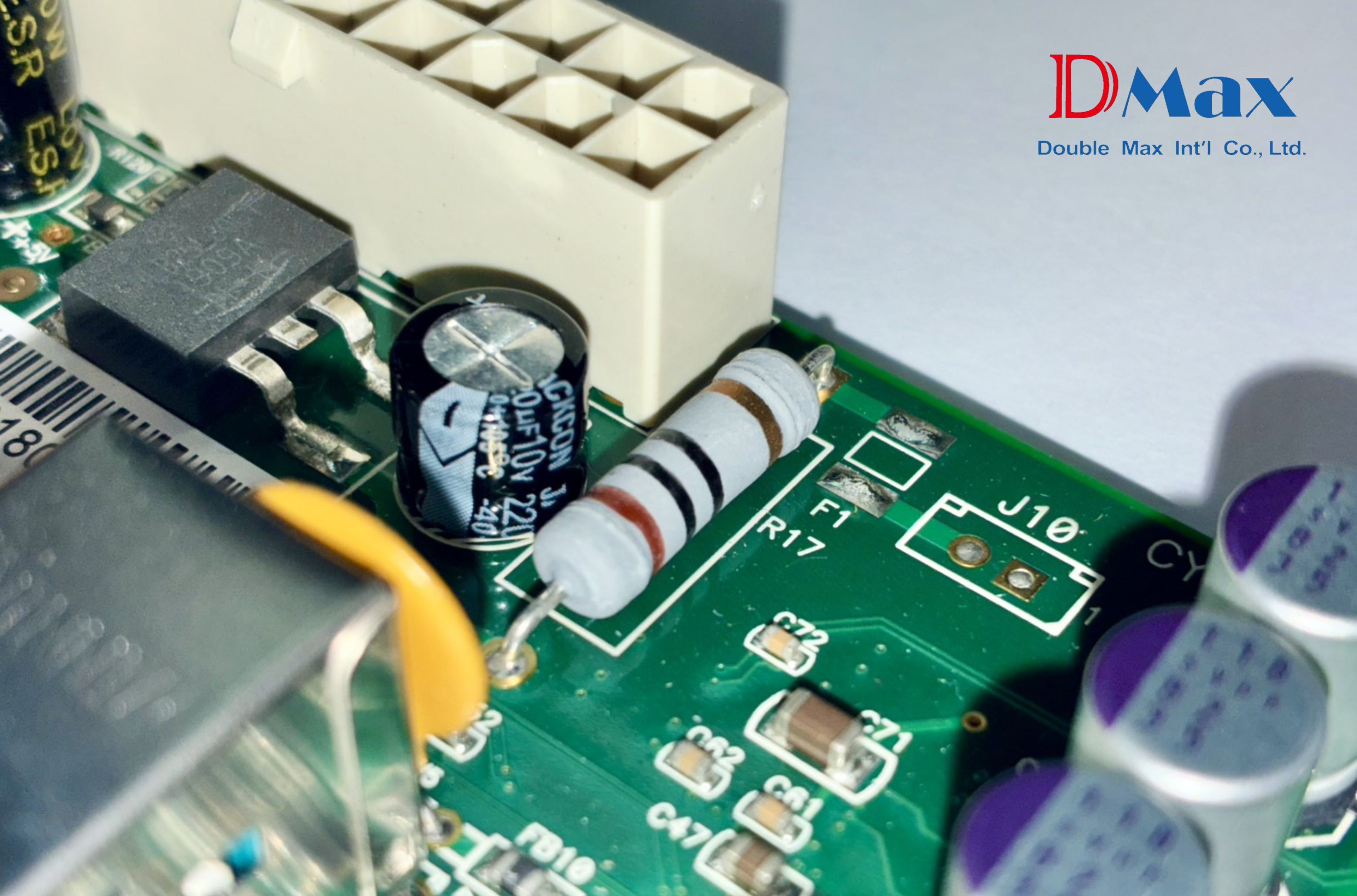

3. SMT / DIP Professional Assembly & Soldering D-MAX's highly professional assembly team will execute the core PCBA assembly process, including SMT (Surface-Mount Technology) and DIP (Dual In-line Package) soldering. We use high-level process technology to produce the highest quality PCBA for you.

4. Quality Inspection D-MAX uses top-tier AOI (Automated Optical Inspection) and X-Ray inspection tools in the industry to ensure PCBA soldering quality.

5. Functional Testing (FCT) As per customer requirements, D-MAX will conduct functional testing on the PCBA to ensure the finished PCBA product is 100% functional and operates stably.

6. Box Build Assembly and Shipment D-MAX offers final-stage system assembly services, installing the PCBA into its enclosure and completing the final product packaging and shipment. From design, procurement, production, quality control, and delivery, we free you from the worries of PCBA manufacturing, allowing you to concentrate more on enhancing your product.

The Core Value of D-MAX's PCBA Turnkey Service

- Simplified Supply Chain: You no longer need to manage dozens of PCBA component suppliers or browse and compare countless PCBA component datasheets. D-MAX will manage it all for you and provide the optimal solution as your dedicated single point of contact.

- Reduced Risk and Cost: D-MAX's professional experience and partner manufacturers can save you from the risks and losses caused by procurement delays or material errors.

- Shortened Time-to-Market: D-MAX will manage the entire PCBA production schedule and shipment for you, allowing you to reserve your valuable time and resources for your core business—Product R&D and Marketing.

Full Turnkey (One-Stop Service / Full Consignment)

"Full Turnkey" is D-MAX's most recommended model and our core service.

Service Definition: The customer (you) only needs to provide the design files (Gerber files and BOM list). D-MAX will act as your single point of contact, responsible for "all" production and manufacturing links. This includes:

- PCB Fabrication

- Procurement of "all" electronic components on the BOM list (including ICs, resistors, capacitors, connectors, etc.)

- Supply Chain Management (including component lead time coordination, IQC, kitting)

- SMT / DIP Assembly & Soldering

- Quality Inspection (AOI, X-Ray)

- Functional Testing (FCT)

You only need to provide D-MAX with the correct PCBA design files and wait to receive the functional PCBA products built for you by D-MAX.

B2B Procurement Advantages:

- Highest Efficiency: Your management cost is reduced to near zero.

- Lowest Risk: D-MAX assumes all supply chain risks, such as component shortages, lead time delays, material errors, etc.

- Focus on Core Business: You can focus 100% of your resources on product R&D and marketing.

RECOMMENDATIONS

_2_cover.png)

_cover.png)