FAQ

What is the difference between PCB and PCBA?

What is the difference between PCB and PCBA?

The difference between PCB and PCBA is the most critical distinction in the electronics manufacturing field and the first key point B2B buyers must clarify when procuring PCBs or PCBAs.

Simply put, a PCB is a bare board; it is a raw material or component. A PCBA, however, is a board with components mounted; it is a product of a process. PCB and PCBA represent two completely different stages in the electronics manufacturing supply chain.

PCB (Printed Circuit Board)

-

Common Aliases: Bare Board, Empty Board, Substrate.

-

Status: A PCB is a "base board" (substrate) on which no electronic components have yet been mounted. A PCB only has the copper traces (for conducting electricity) and pads (for positioning components) "printed" onto it according to the circuit design files.

-

Function: A PCB itself does not have any electronic function. The sole purpose of a PCB is to serve as a platform (or skeleton) to "support" the components that will be mounted later and to "provide" the electrical connection paths between those components.

PCBA (Printed Circuit Board Assembly)

-

Common Aliases: Assembled Board, Finished Board, Mounted Board.

-

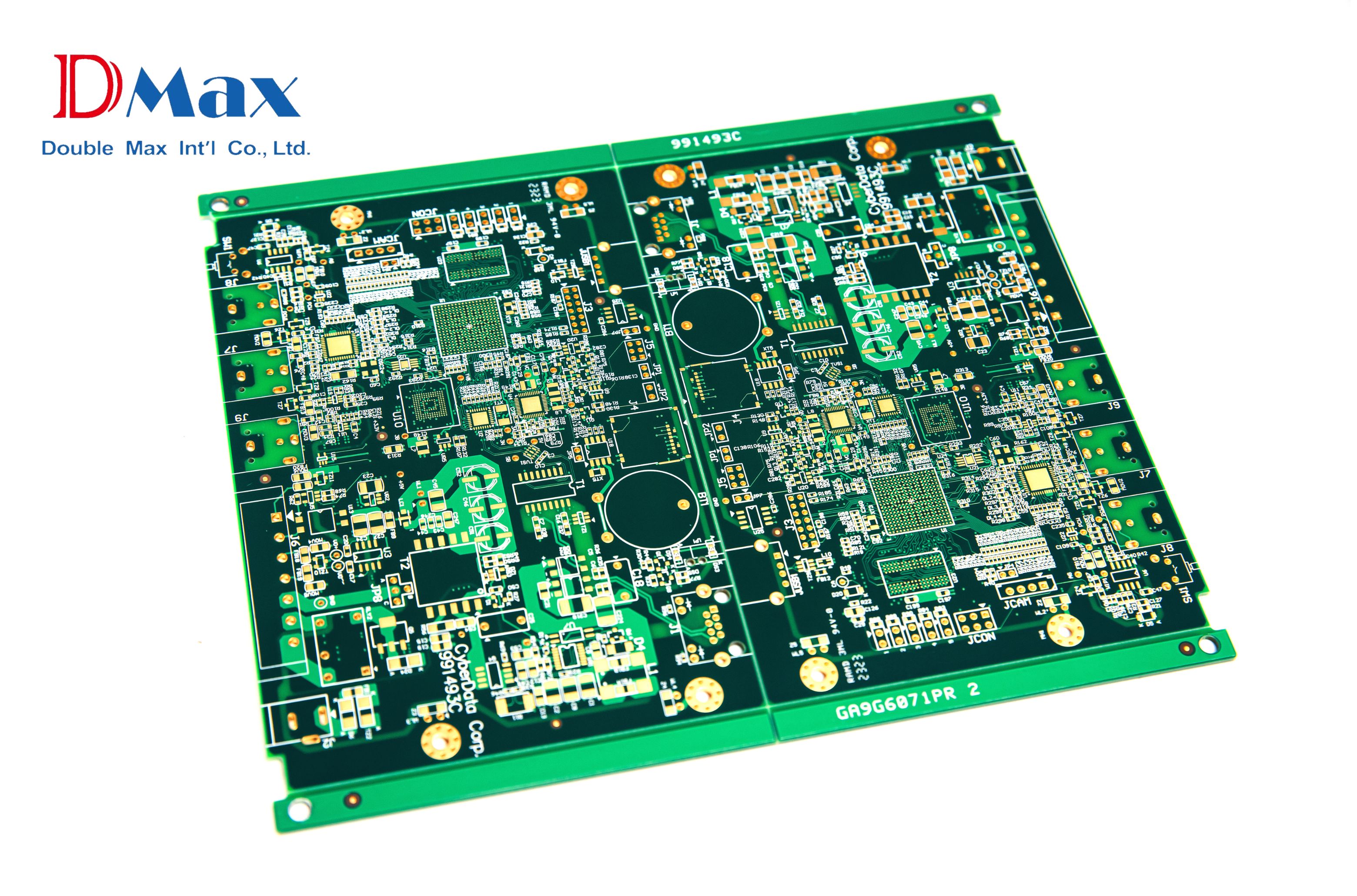

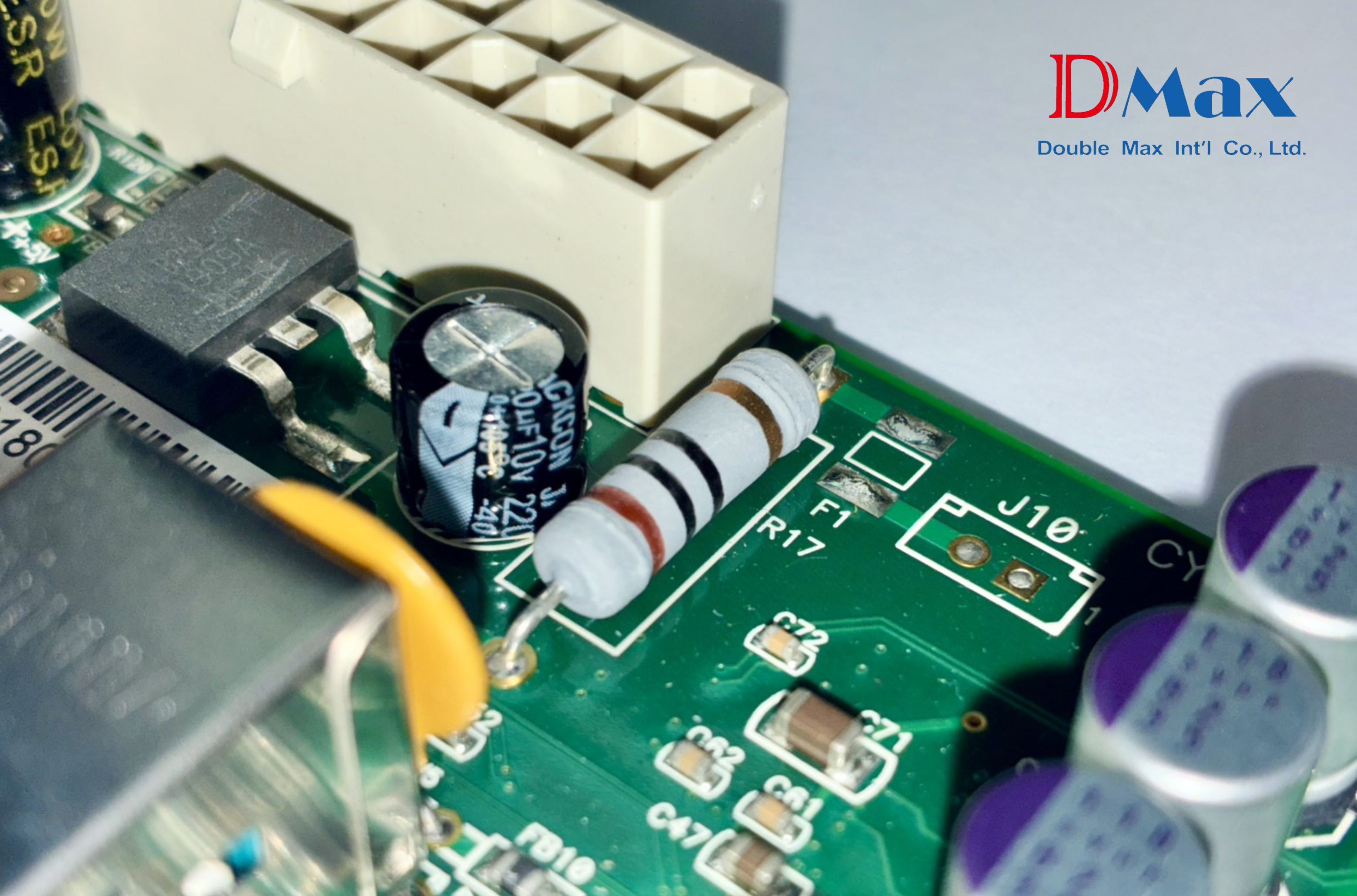

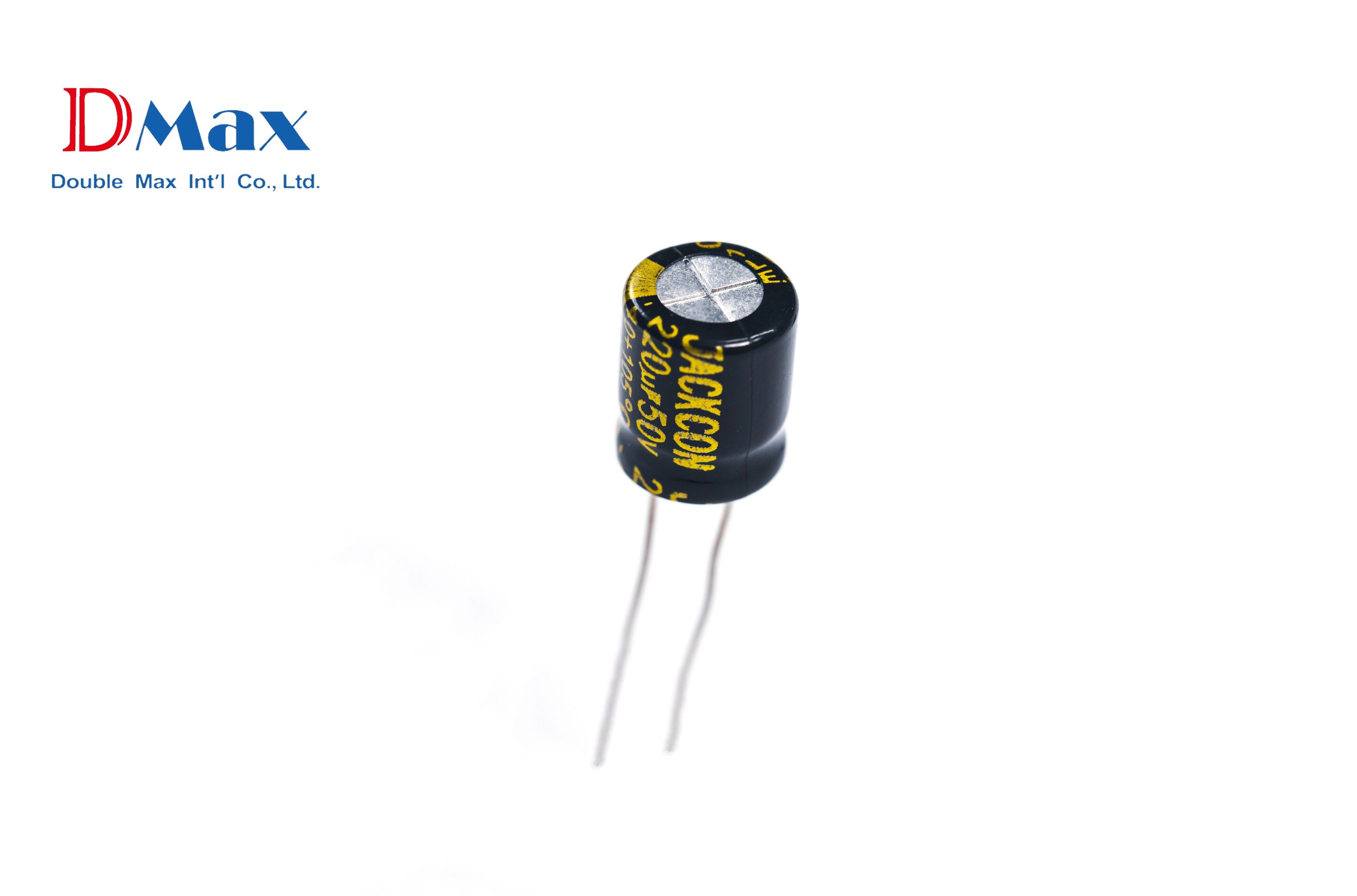

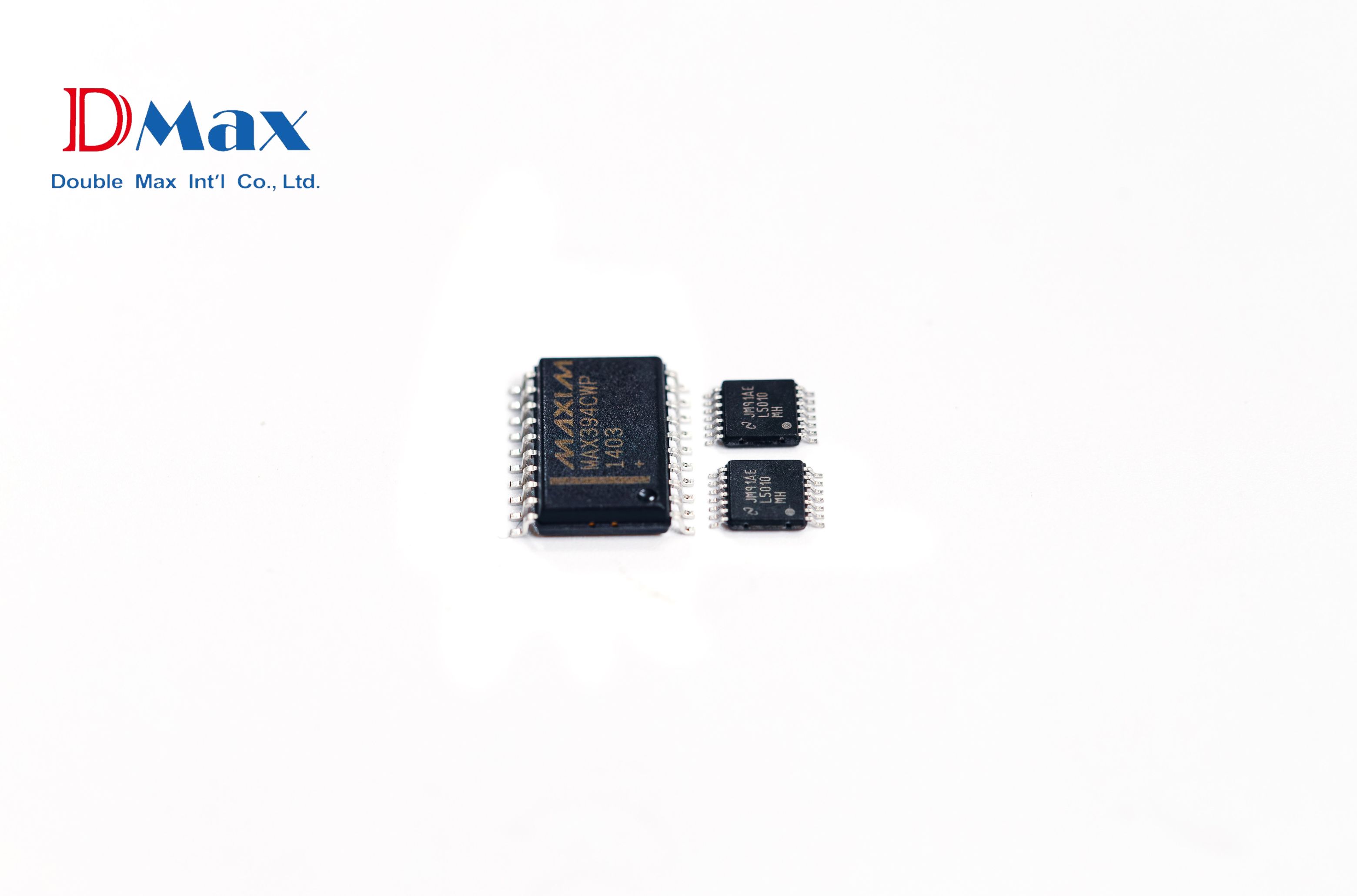

Status: A PCBA starts with a bare PCB (bare board) and undergoes professional processes like SMT or DIP to "Assemble" and "Solder" all necessary electronic components (like ICs, resistors, capacitors) onto it, resulting in a "functional circuit board."

-

Function: A PCBA is a board with specific capabilities. When powered, it executes computations, controls, or signal conversions. It is the "vital heart" that drives electronic products.

The fundamental difference lies in the "A" (Assembly) in PCBA. This "A" represents the high-tech, complex process of transforming a "design blueprint" into a "functional entity," which includes SMT (Surface-Mount Technology), DIP (Dual In-line Package), Reflow Soldering, Wave Soldering, and subsequent AOI Inspection and Functional Testing (FCT).

D-MAX's core expertise is providing high-quality, high-reliability PCBA assembly services. We are responsible for transforming your designed PCB, through our sophisticated assembly processes, into a fully functional PCBA finished product that can power your end device, allowing your product to operate with high quality and stability.

What are the types of PCB?

The types of PCB are determined by their physical structure and layer count. The bare PCB is the foundation, and its classification is physical, determined at the time the bare board is manufactured.

By "Physical Structure":

-

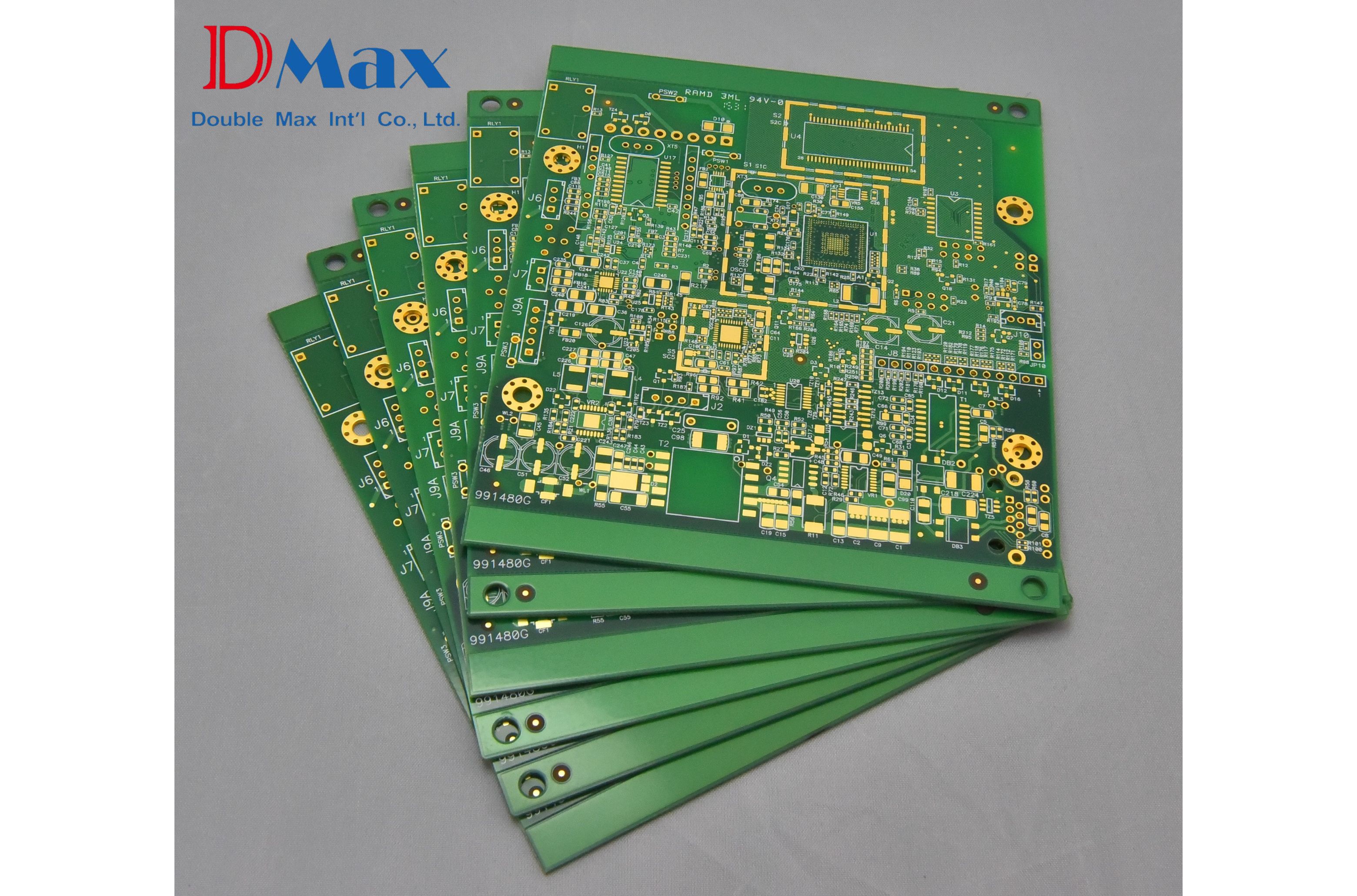

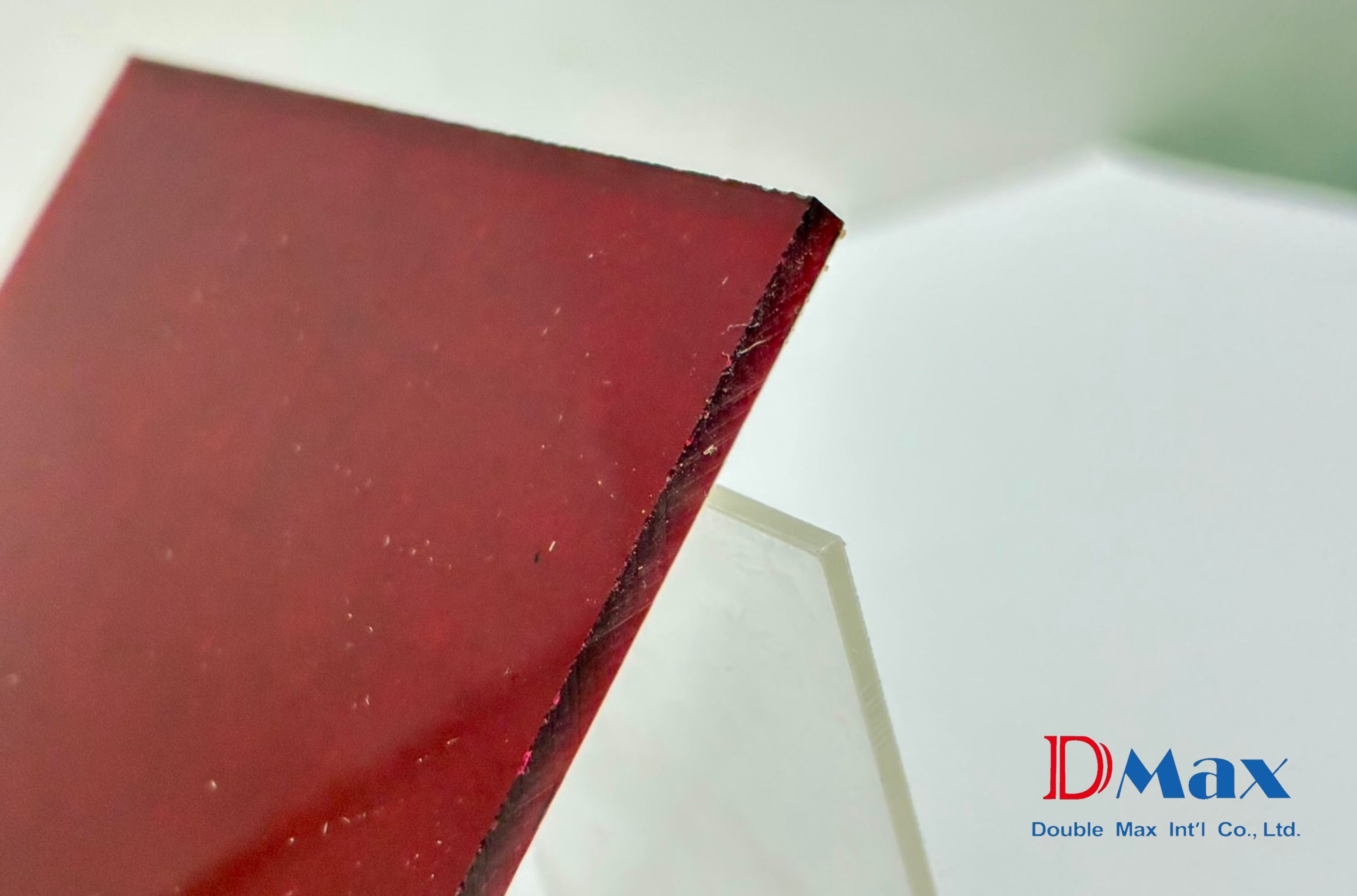

Rigid PCB: This is the most common material used for PCBs. It is made of rigid insulating material like FR-4 (fiberglass), cannot be bent, is very robust, and provides stable mechanical support for the PCB.

-

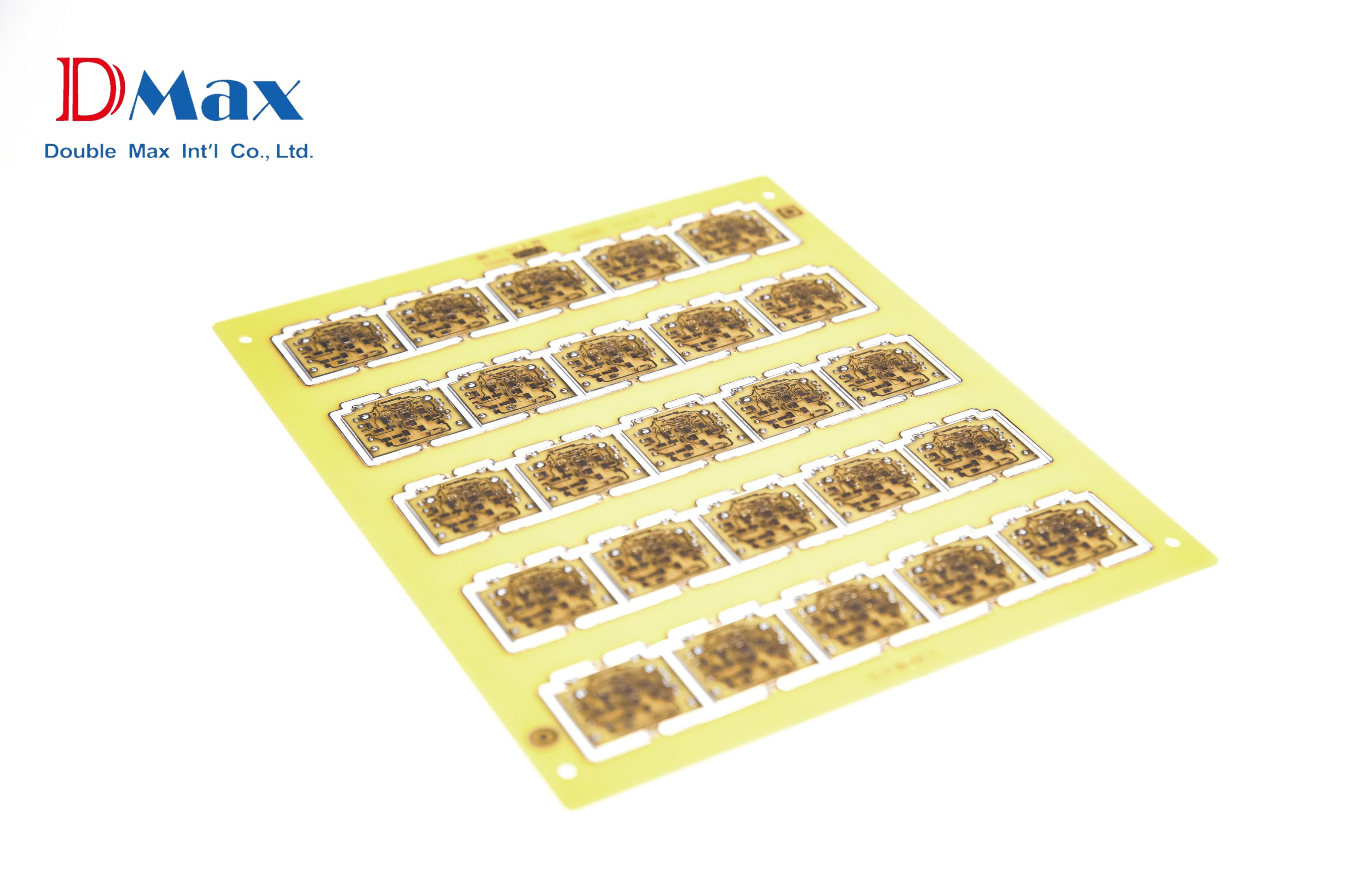

Flexible PCB (FPC): Made of flexible materials like Polyimide (PI), this allows the circuit board to bend, enabling the PCB to fit into small or irregular product spaces (e.g., camera lens modules).

-

Rigid-Flex PCB: This material combines the stability of a rigid board with the flexibility of a flex board. It is the most structurally complex and highest-cost PCB type, often used in aerospace, defense, or medical equipment.

By "Circuit Layer Count":

-

Single-Layer PCB: Traces are on only one side of the PCB.

-

Double-Layer PCB: The PCB has traces on both the top and bottom layers.

-

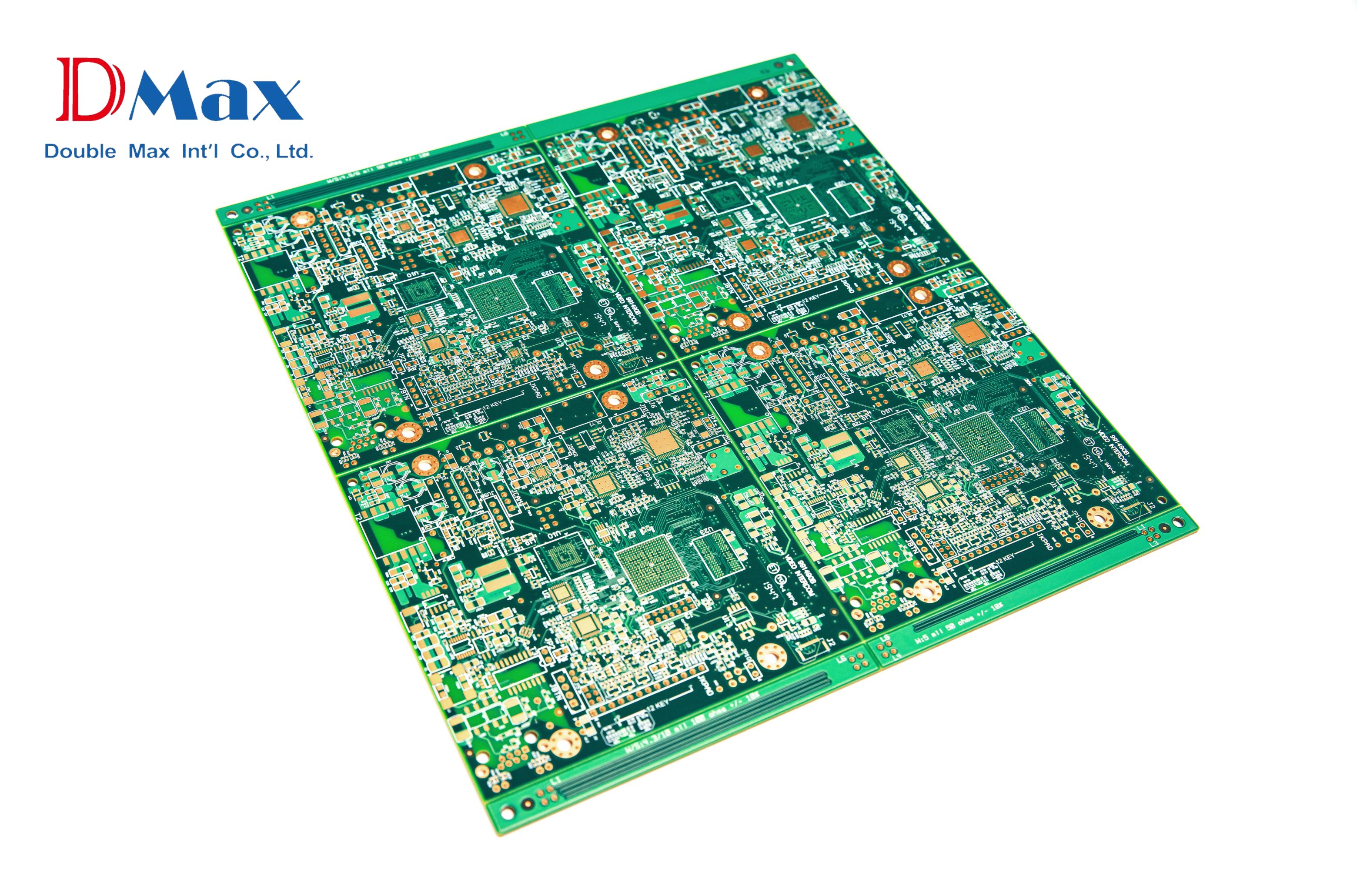

Multi-Layer PCB: Formed by pressing multiple double-layer boards together, with internal layers also containing circuitry. The more layers, the more complex and costly the PCB (e.g., computer motherboards, servers).

What are the types of PCBA?

Since a PCBA is an extension and application of a PCB, it naturally inherits the basic types of the PCB (for example, we would say "this is a Flexible PCBA" or a "Multi-Layer PCBA").

Therefore, when we discuss types of PCBA, we tend to focus on classifications based on the "method and difficulty of the PCB Assembly".

By "Assembly Technology":

-

SMT PCBA: The entire board is assembled using only SMT (Surface-Mount Technology).

-

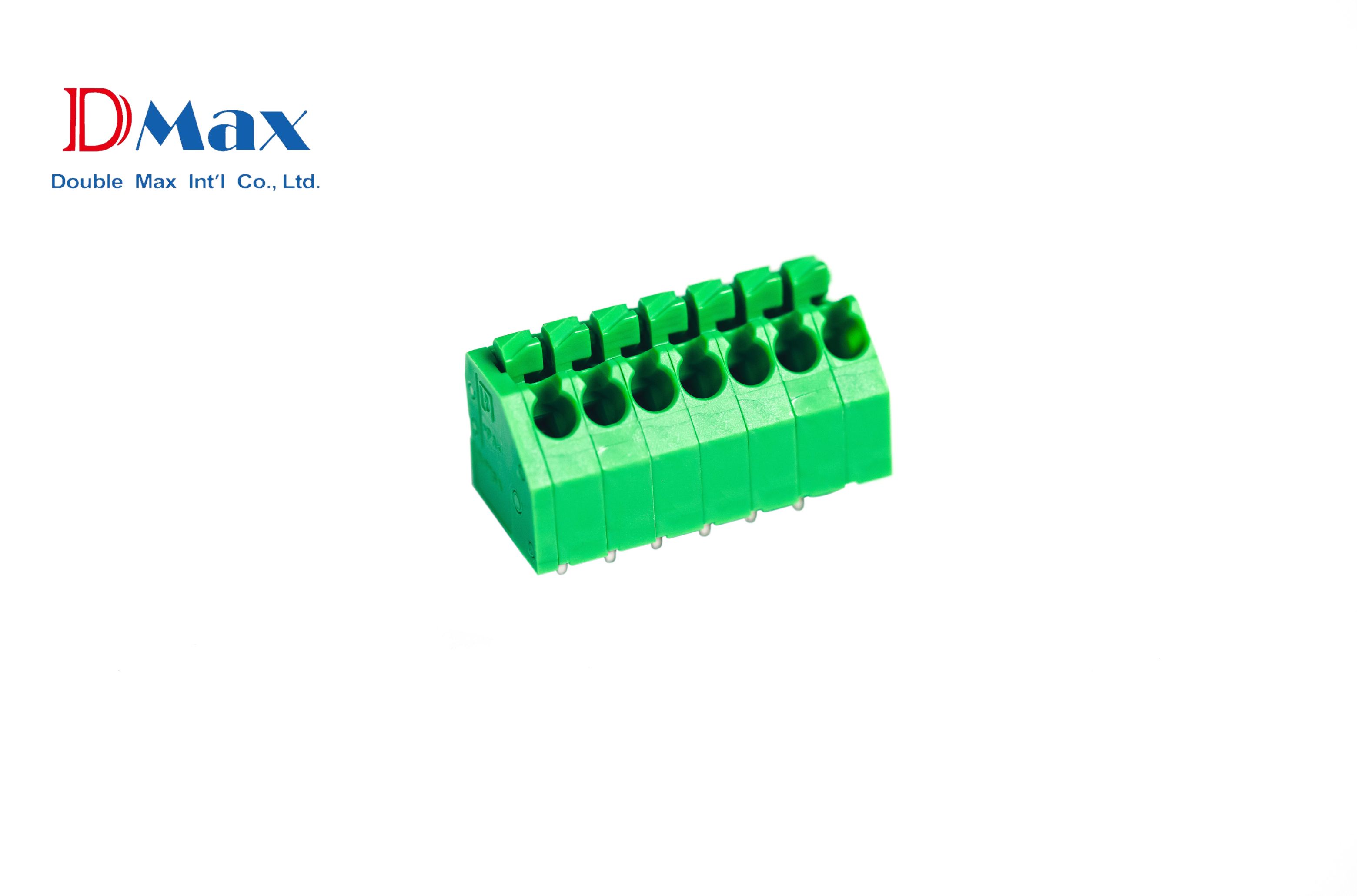

DIP PCBA: The entire board is assembled using only DIP (Dual In-line Package), which is very rare now.

-

Mixed-Technology PCBA: This is the most common type. A single board contains both SMT and DIP components, requiring two different processes: SMT reflow and DIP wave soldering.

By "Assembly Side":

-

Single-Sided Assembly: All electronic components are mounted on only one side of the PCB (usually the Top side).

-

Double-Sided Assembly: Both the top and bottom layers of the PCB have components mounted on them. This significantly increases the process complexity, as the already-soldered components on the first side must be protected while soldering the second side, leading to notable increases in manufacturing cost and time.

RECOMMENDATIONS

_2_cover.png)

_cover.png)